Taxus chinensis solid air freshener and preparation formula and preparation method thereof

A technology of an air freshener and a manufacturing method, applied in the directions of deodorization, disinfection, etc., can solve the problems of high production cost, the extraction process of yew extract is not clearly given, and the volatility is poor, and the effect of relieving tension is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of manufacture method of yew solid air freshener, this method comprises the following steps:

[0027] A. Preparation of homogenate: dry and pulverize the branches and leaves of the yew plant to obtain crushed branches and leaves; mix the crushed branches and leaves with an appropriate amount of water, then add an appropriate amount of non-volatile inorganic acid, and homogenize after swelling to obtain a homogenate ;

[0028] B. Preparation of base liquid: pass the homogenate into steam distillation, condense to obtain a distillate, then place the distillate for stratification, take the upper oil phase of the distillate and part or all of the lower water phase to obtain the base liquid;

[0029] C. Solidification and molding: add gelling agent and preservative to the base liquid, mix and heat until completely dissolved to obtain a liquid mixture; pour the above liquid mixture into a mold to cool and form, and after demolding, the yew solid air freshener is obtain...

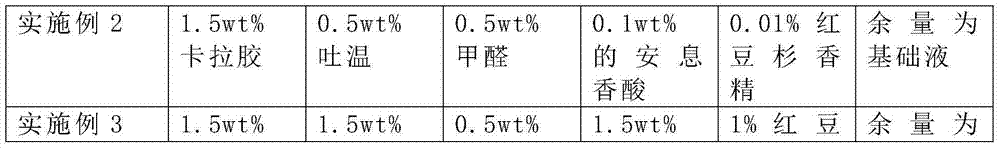

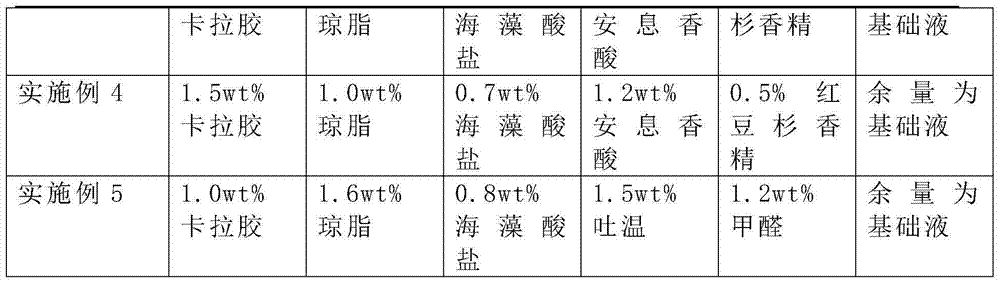

Embodiment 2-5

[0042] The working process of the embodiment here is basically the same as that of the embodiment 1, the difference is that in step C, solidification and molding: the mass numbers of the gelling agent and preservative added to the base liquid are different, see the table below for details .

[0043]

[0044]

Embodiment 6

[0046] Take southern yew [Taxus chinensis (Pilger) Rehd] branches with a diameter of less than 1cm that were pruned at the end of autumn, place them in a cool and dry place until the leaves begin to fall off naturally, dry at 60°C until they can be easily broken, and then cut the branches to 3 -5cm strips, pulverized, and passed through a 60-mesh sieve to obtain yew powder. The yew powder is mixed with the fallen leaves, and then mixed with water at a mass ratio of 1:6-1:3. As preferably, in this embodiment, mixed with a mass ratio of 1:5, in the mixed object Add 1.0wt% phosphoric acid, let it swell until there is no obvious liquid, and homogenate. After homogenization, steam distillation at 100°C for 240 minutes, collect the distillate in the condenser, and separate the distillate into layers. Separate the distillate, take the upper oil phase, and the lower water phase whose volume is 30 times that of the upper oil phase to obtain the base liquid, add 2.5wt% carrageenan, 1.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com