Amorphophallus konjac continuous washing machine

A washing machine, konjac technology, applied in the application, food processing, food science and other directions, can solve the problems of labor, affecting production costs, low output, etc., to achieve continuous washing operation, large-scale processing and production reduction, and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

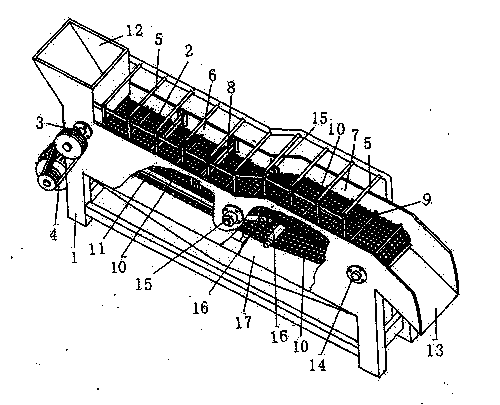

[0012] figure 1 As shown: above a strip-shaped body 1, a immersion tank 6 and an integrated flushing tank 7 are arranged, and an endless chain belt 2 is arranged in series, and the chains 10 on both sides of the endless chain belt 2 pass through the two ends. The transmission gear shaft 3 and the built-in gears of the driven gear shaft 14 mesh to form a circular rotation structure; several water spray pipes 5 that can spray water into the immersion tank 6 and the rinse tank 7 are arranged on the top of the body 1; There are several detachable brushes 8; there is a feed port 12 above the front end of the body 1, and a discharge port 13 is provided at the tail; The two sides are tightly fixed with the body 1, and the two ends are inclined upward to leave a space for the loop chain belt 2 to rotate and circulate. A plurality of scrapers 9 are distributed on the endless chain belt 2 . On both sides of the endless chain belt 2 in the middle of the body 1, there is a pressure whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com