Automatic precisely-weighing tea pressing machine

A tea press, automatic technology, applied in the field of machinery, can solve the problems of insufficient product hygiene and safety, unstable quality, inaccurate quantification, etc., and achieve the effect of easy maintenance, high labor intensity and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

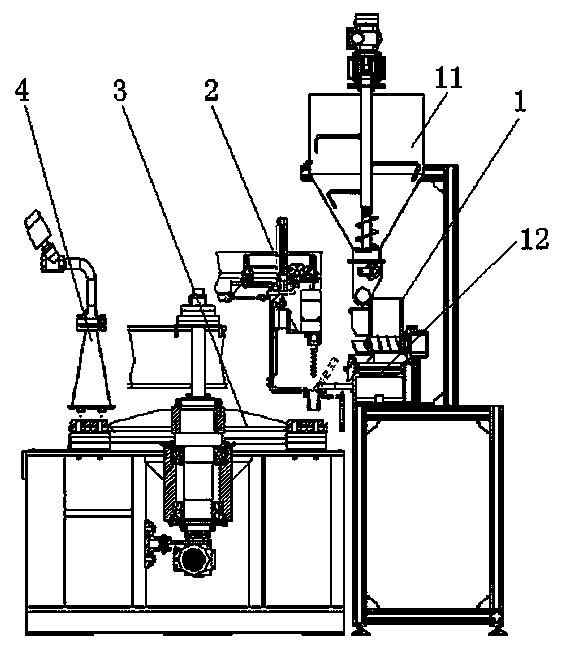

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The automatic quantitative tea pressing machine provided by the present invention includes a turntable 3 with a hole for holding tea, a charging leveling mechanism 2 distributed around the turntable 3 and matched with the hole for holding tea on the turntable 3, a steamed tea softening mechanism 4, and a tea pressing mechanism. Mechanism 6, demoulding mechanism 5, and weighing mechanism 1 matched with charging leveling mechanism 2;

[0030] Described weighing mechanism 1 comprises feed bin 11, is provided with conventional vertical screw feeder in feed bin 11, and feed bin 11 outlet is provided with conventional horizontal screw feeder 111, and below this horizontal screw feeder 12 is connected with weigher 12 ; The weighing device 12 includes a first weighing device that is matched with the outlet of the silo 11, and a fine weighing device that is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com