Pinellia ternate harvester and harvesting method

A technology of harvester and pinellia, applied in the field of harvester, can solve the problems that the rotation speed of the rotary harrow shaft cannot be changed, the working efficiency of the machine is low, and the harvesting efficiency is not high, so as to achieve the effect of compact structure, simple design and improved harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

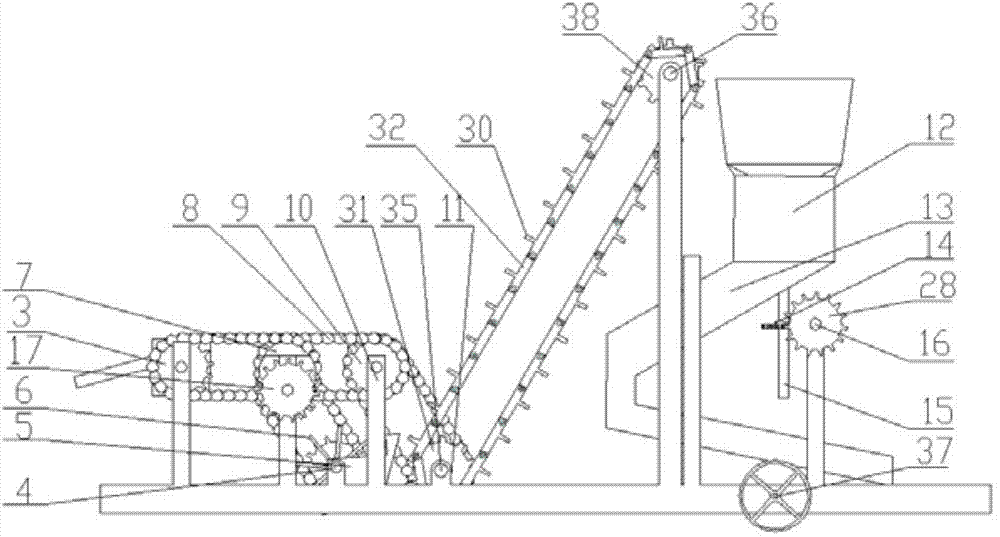

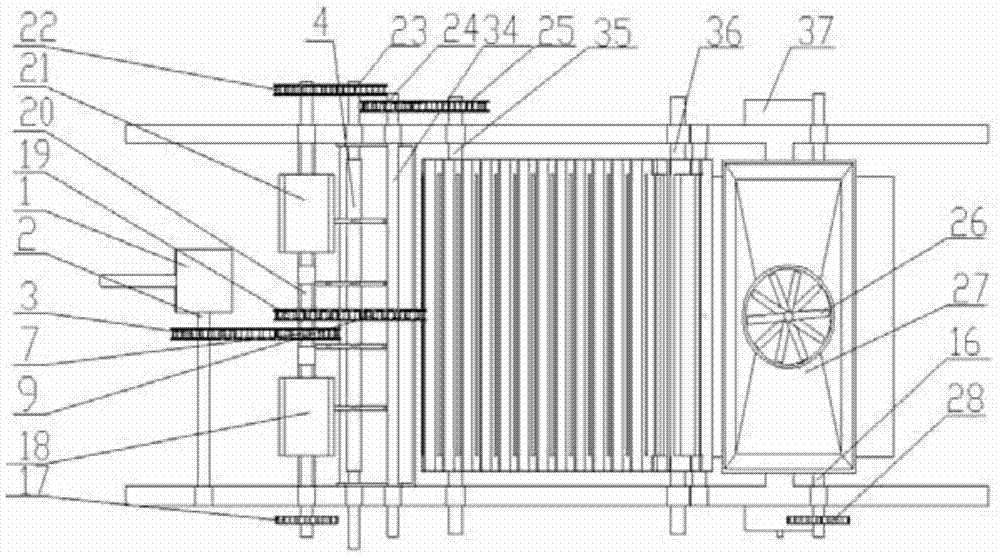

[0026] Such as figure 1 , 2 Shown, a kind of pinellia harvester comprises the output shaft 2 of the tractor gearbox 1 fixed on the frame 10, the first sprocket wheel 3 installed on the output shaft, and the second sprocket wheel forming a chain drive with the first sprocket wheel. Sprocket 7 has the third sprocket 19 that rotates synchronously on the first frame support shaft 20 where the second sprocket is located, and is connected with the chain 8 between the third sprocket and the sixth sprocket 9, where the third sprocket is The first speed changer 18, the second speed changer 21 are equipped with respectively at the two ends of the first frame support shaft, the fourth sprocket wheel 17 is installed on the output shaft of speed changer one, and the fifth sprocket wheel 22 is installed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com