A Servo Loop Control System and Control Method for Oil Slick Supporting Inertial Instrument

An inertial instrument and servo loop technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of inconsistent models, slow heat dissipation, smaller system damping, etc., to achieve a safe and reliable degree of automation, high degree of automation, control high precision effect

Active Publication Date: 2016-05-04

BEIJING INST OF AEROSPACE CONTROL DEVICES

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the complex application environment of the instrument and slow heat dissipation, the actual stable temperature of the oil slick is likely to be higher than the preset temperature point. The increase in the temperature of the oil slick will cause the system damping to become smaller, so that the servo loop design correction network does not match the actual application object model, and the system The stability margin becomes smaller

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

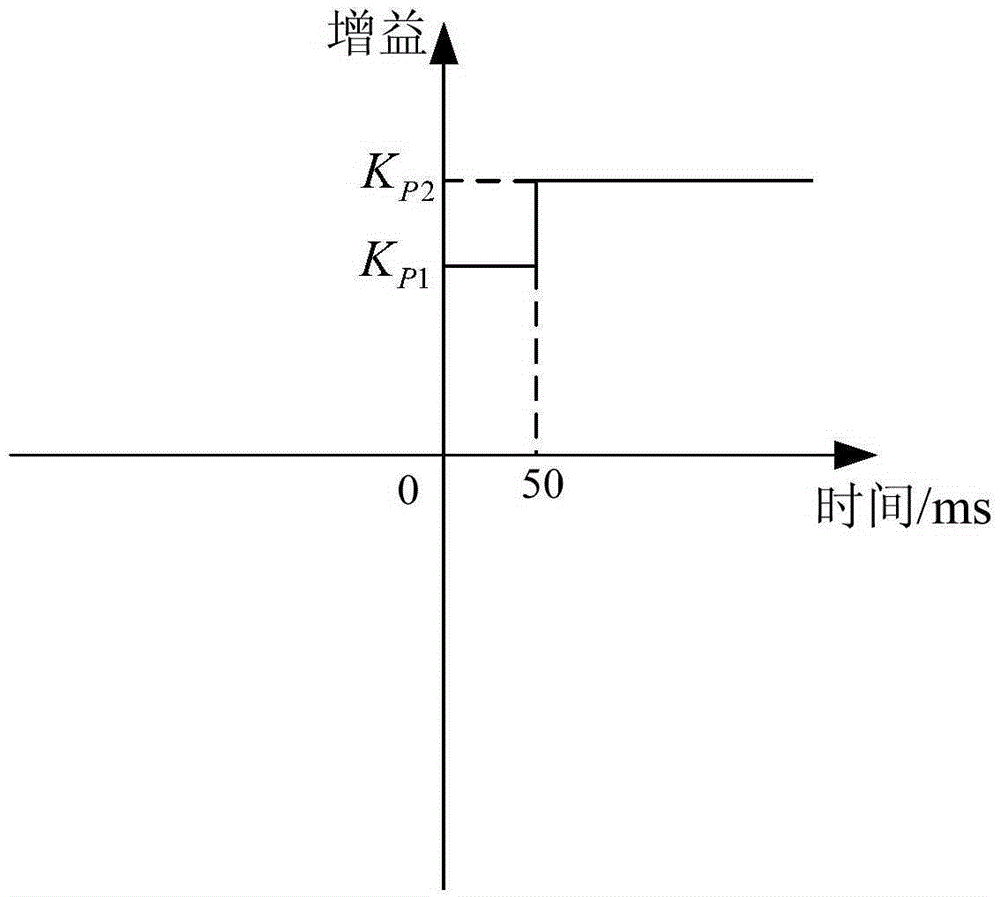

[0024] A set of gyro accelerometer design parameters are given below, and the thresholds of the above temperature points are T 1 =54℃, T 2 =56℃, T 3 =58℃, T 4 =60℃; the corresponding gain within the threshold is K H =4.0,K M =3.5,K L =3.2, the measured system stability margins all meet the design requirements of amplitude margin>10dB and phase angle margin>40 degrees. K P1 is 3.0.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

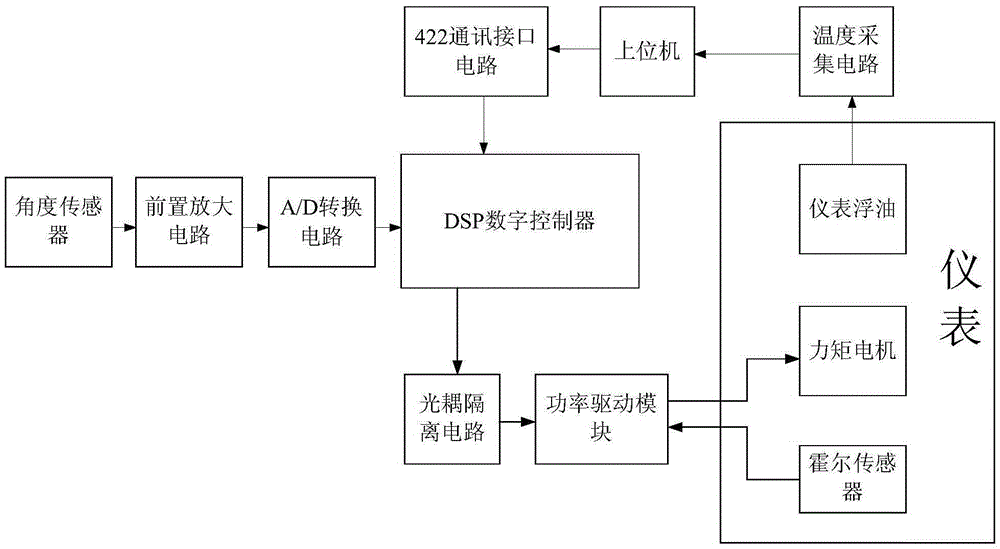

The invention discloses a servo loop control system and control method for a floating oil support inertia instrument. The control system mainly comprises an angle sensor, a front positioned amplification circuit, an A / D (analog / digital) conversion circuit, a DSP (digital signal processor) digital controller, a photocoupling isolation circuit, a power driving module, a moment motor, a hall sensor, a 422 communication interface circuit, a temperature collection circuit and an upper computer. The nonlinear control in the starting stage of the control system and the temperature gradient precise control of an instrument servo loop are respectively realized by introducing a variable parameter correction network DSP digital controller. The upper computer collects the floating oil temperature information in the instrument by the temperature collection circuit and sends the information to the DSP digital controller by the 422 communication interface circuit. The DSP digital controller compares the temperature with a given temperature threshold value and calls corresponding control parameters, so the variable parameter servo control for different temperatures of the instrument is realized. The control system is high in integration degree, high in control precision, high in automation degree, safe and reliable.

Description

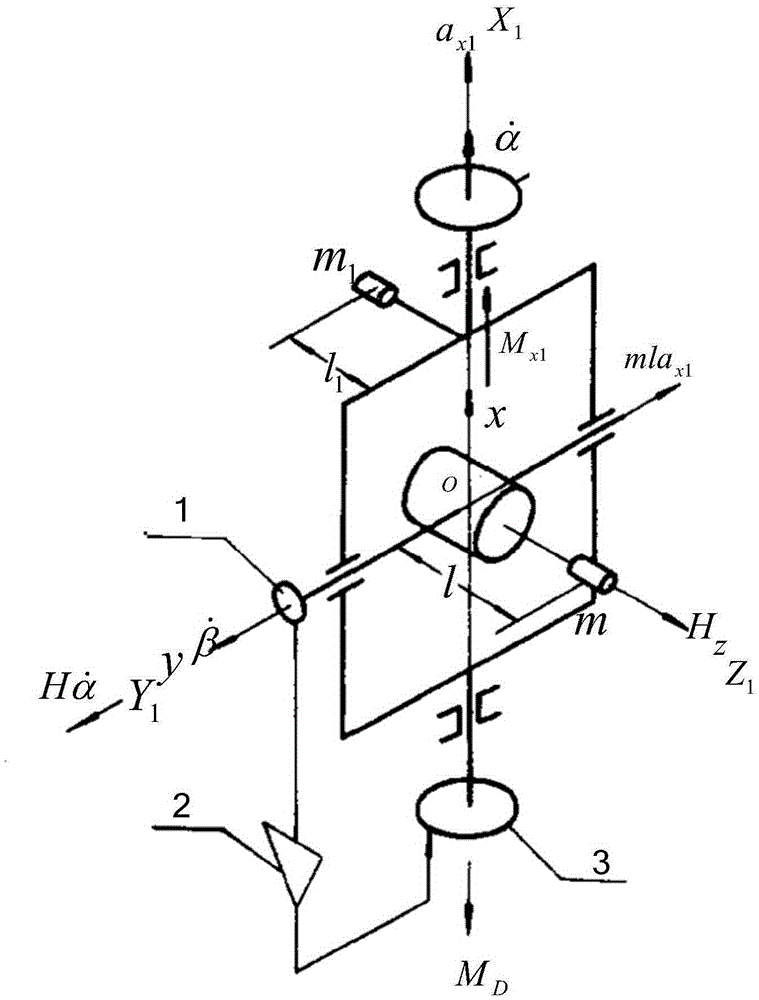

technical field [0001] The invention relates to a servo loop control system and a control method for an inertial instrument supported by slick oil. Background technique [0002] Taking the gyro accelerometer as an example, the principle of the oil slick supporting the inertial instrument is explained below. Such as figure 1 As shown, the outer ring coordinate system of the gyro accelerometer is OX 1 Y 1 Z 1 ,OX 1 is the axis of the outer frame, OY 1 is the axis of the inner frame, OZ 1 is the angular momentum direction of the motor, , are the angular velocities of the outer frame relative to the instrument base and the inner frame relative to the outer frame, respectively, M X1 is the sum of various disturbance moments around the outer frame axis, M D Torque generated by the torque motor. The shaft of the inner frame is supported by slick oil. Due to the disturbance moment M on the axis of the outer frame X1 influence, the angular momentum H will slowly move t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02P23/00G01C21/16

Inventor 章丽蕾严小军张沛晗岳辉杨志超周敏

Owner BEIJING INST OF AEROSPACE CONTROL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com