Stripping and cutting device for cables

A cutting device and cable technology, applied in the direction of cable installation device, cable installation, line/collector parts, etc., can solve the problems of frequent movement, slow screw speed, easy damage of peeling and cutting mechanism, etc., and reach the service life The effect of long length, simple movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

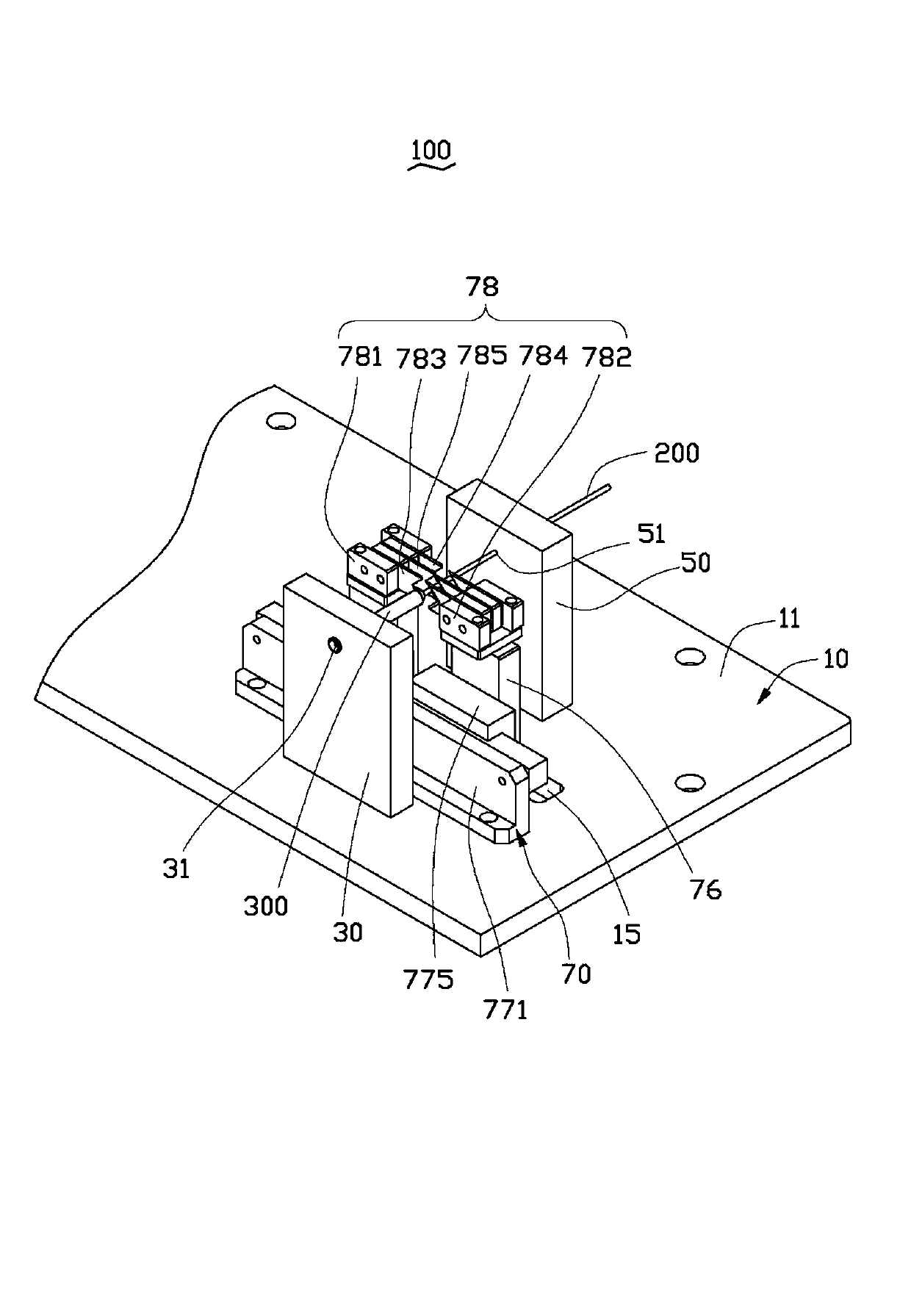

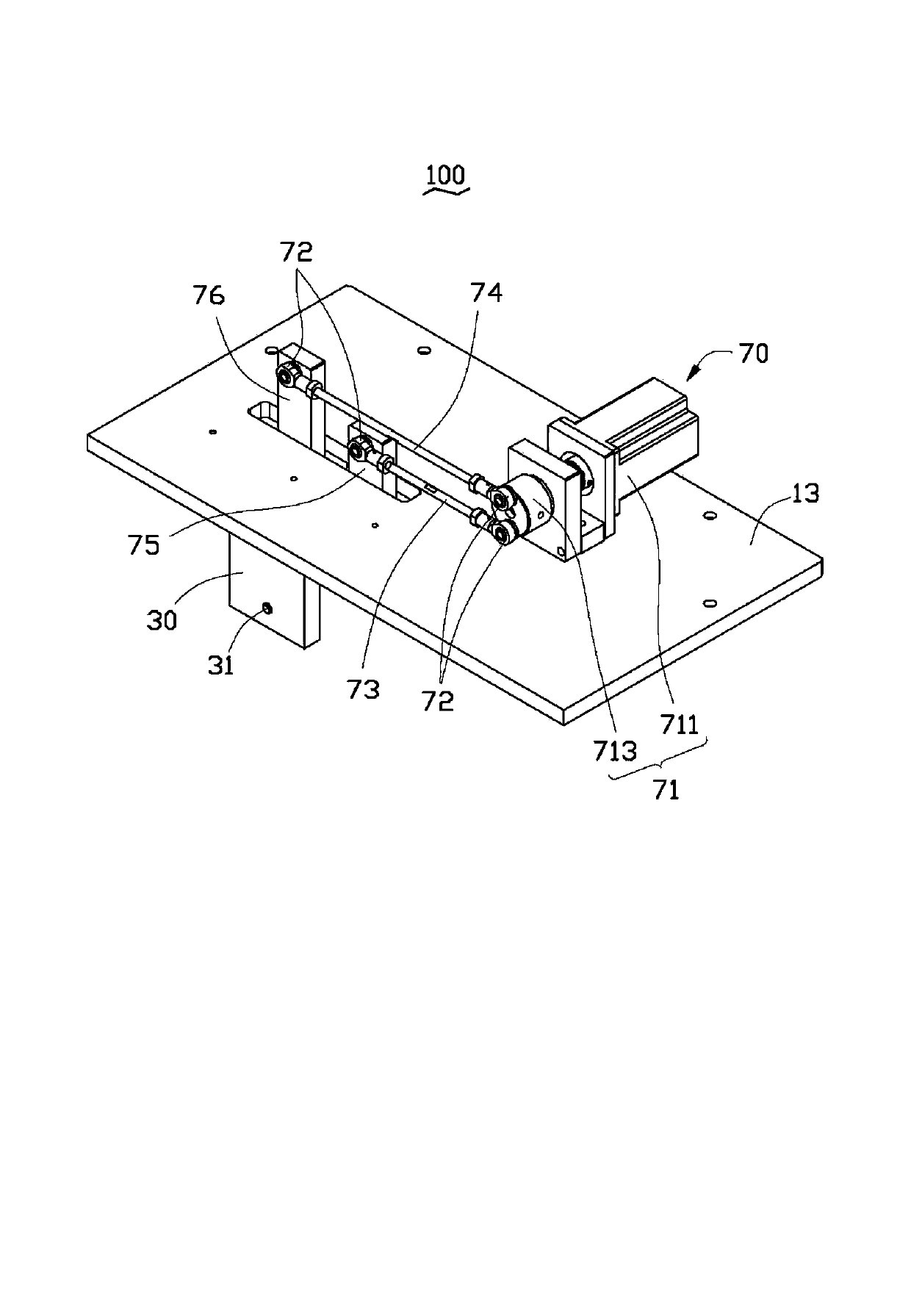

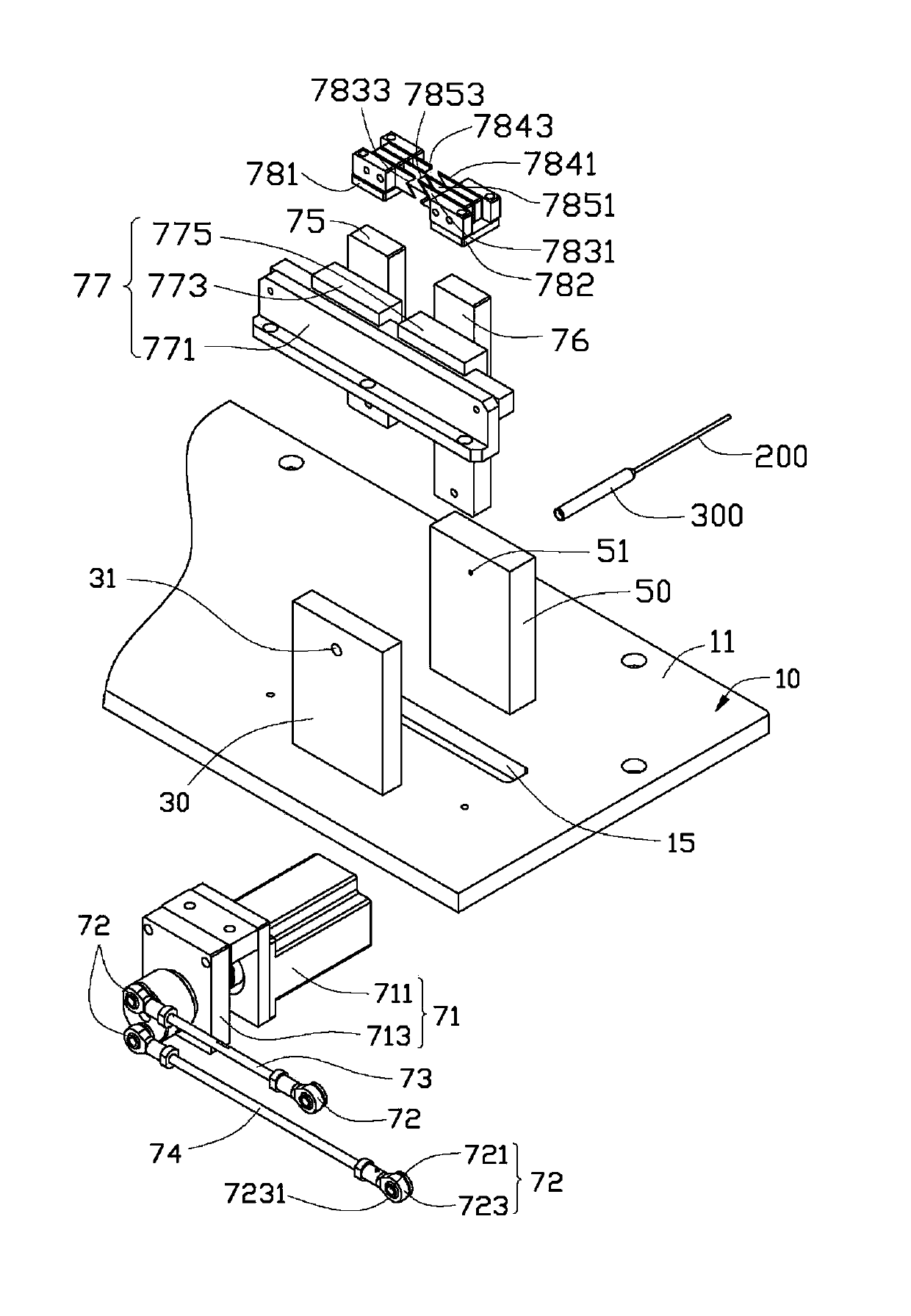

[0012] Please also see Figure 1 to Figure 3 , The cable stripping and cutting device 100 according to the embodiment of the present invention includes a mounting plate 10 , a first stripping member 30 , a second stripping member 50 and a cutting mechanism 70 . The first stripping part 30, the second stripping part 50 and the cutting mechanism 70 are all mounted on the mounting plate 10, the first stripping part 30 fixes the wire barrel 300 through which the cable 200 is passed, and the second stripping part 50 fixes the cable 200 away from the end of the wire barrel 300 . The cutting mechanism 70 is used to cut off the coating layer (not shown) and the core wire (not shown) of the cable 200. The first stripping member 30 and the second stripping member 50 cooperate with the cutting mechanism 70 to separate the coating layer from the core after cutting. Stripped on the line.

[0013] The installation board 10 is substantially rectangular and includes a first surface 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com