Terminal compression joint device

A crimping machine and terminal chain technology, which is applied in connection, electrical components, circuits, etc., can solve the problems of frequent faults in the use of automatic crimping machines, easy entanglement of feeding wire harnesses, and increased product scrap rate, so as to reduce frictional production Heat, reduce production costs, reduce the effect of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

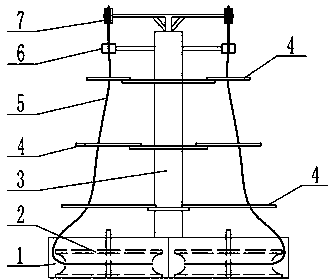

[0009] Depend on figure 1 It is known that a terminal crimping device is composed of a motor 1, a body 2, an upper mold 3, a pusher 4, a lower mold 5, a winding device 6, and a terminal chain 7. The body 2 and the lower body are fixed on the workbench. The mold 5, the motor 1 is set on the top of the fuselage 2, the upper mold 3 is set on the bottom of the fuselage 2 and cooperates with the lower mold 5, and the winding device 6 is set on the side of the fuselage 2, according to the processing technology of the terminal chain 7 It is required to set the parameters of the programmable controller, adjust the gap between the upper mold 3 and the lower mold 5, install the terminal chain 7 on the winding device 6, the terminal chain 7 passes through the support frame, and finally sends it to the lower mold 5 , step on the starting pedal, the upper mold 3 reciprocates up and down under the action of the motor 1, the terminal chain 7 is pushed to the appropriate position of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com