Film paving monitoring device for powder resin covering filter

A powder resin, monitoring device technology, applied in measurement devices, optical devices, program control in sequence/logic controllers, etc., can solve the problems of low degree of automation, limited observation range, no quantitative analysis methods, etc. Simple operation, small number of equipment, and the effect of improving the level of automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

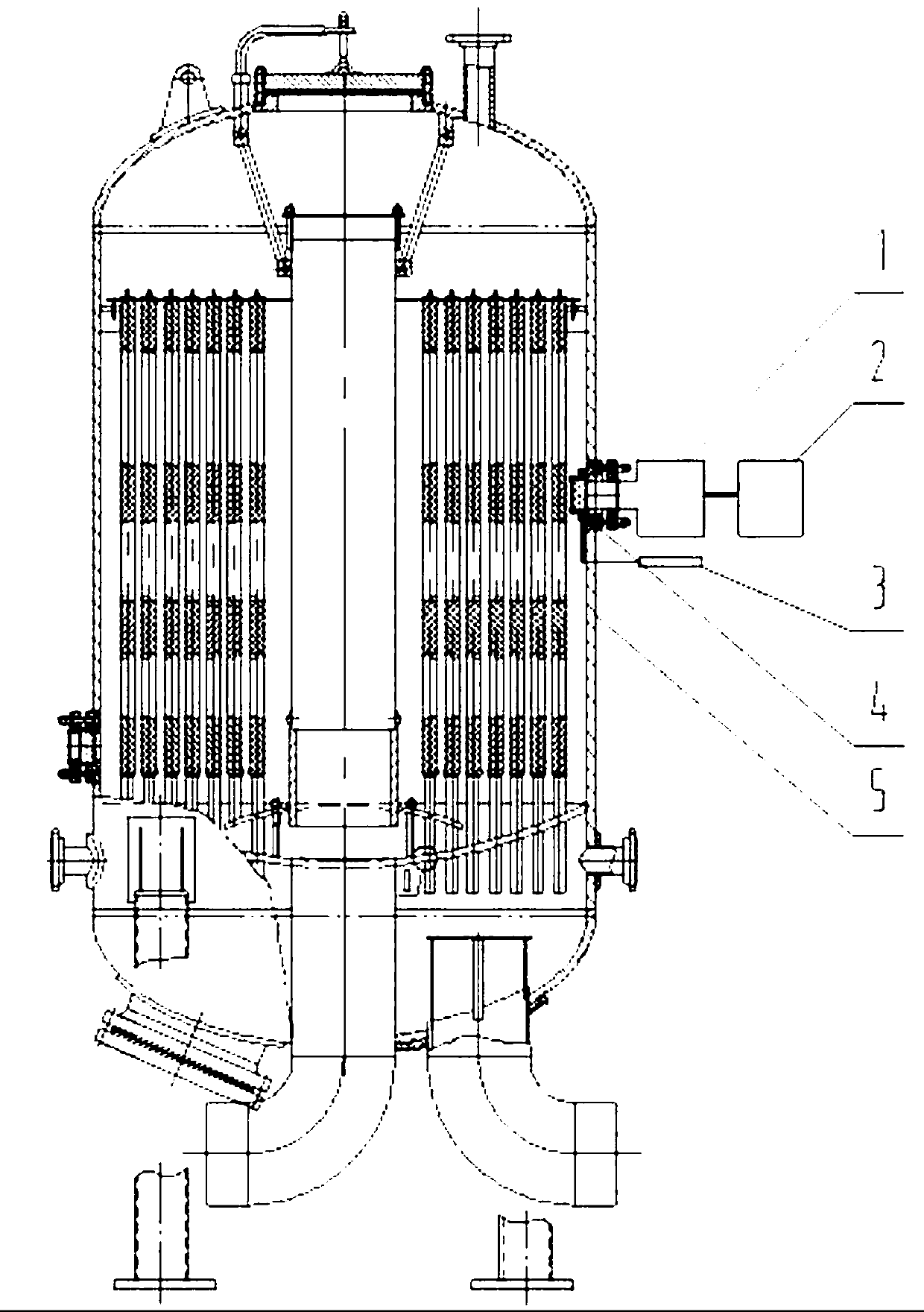

[0022] Examples of this patent: as figure 1 As shown, it is the core processing equipment of the condensate polishing system in the thermal power plant of the air-cooling unit, mainly including: infrared waterproof camera monitoring and detection equipment (1), intelligent calculation controller (2), ultrasonic cleaning device ultrasonic generator (3), Ultrasonic cleaning device Ultrasonic vibrating plate (ring shape) (4), powder resin covering filter (5).

[0023] Through the infrared waterproof camera monitoring and detection equipment (1) installed at 2 / 3 of the height of the straight edge of the powder resin-covered filter (5), the operation of the powder resin-covered filter and the surface shape of the filter element during the film laying process, filter Meta install fixed case. Infrared waterproof camera monitoring and detection equipment (1) has both video monitoring and film thickness measurement functions, and can continuously measure the film thickness online. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com