Output calibration method for public-viewpoint naked-eye true three-dimensional display system

A technology of three-dimensional display and calibration method, which is applied in optics, instruments, projection devices, etc., can solve the problems of weak trapezoidal correction function, high difficulty of calibration accuracy, and limited adjustment range, so as to reduce manpower and time consumption, projection The effect of precise area and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

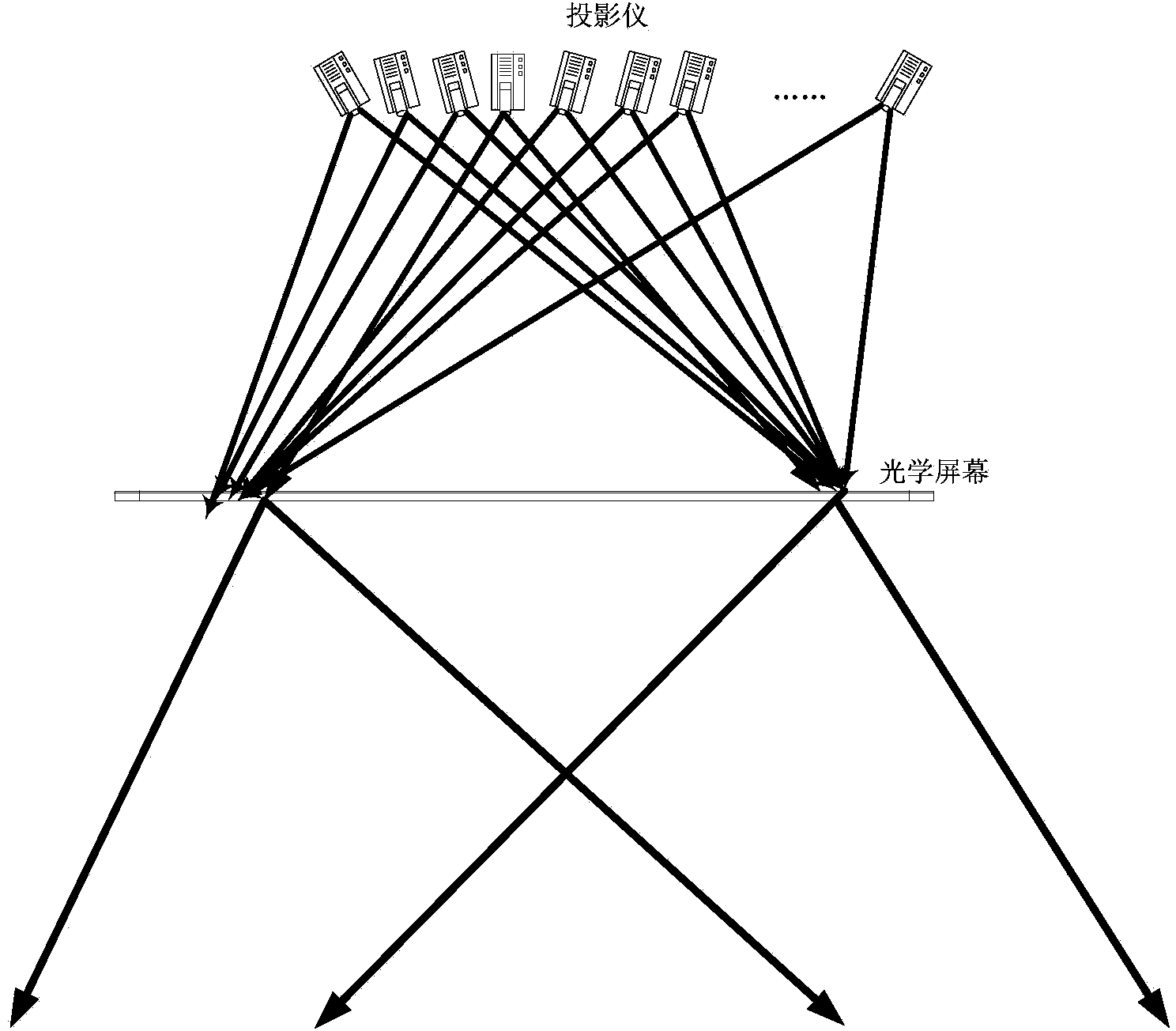

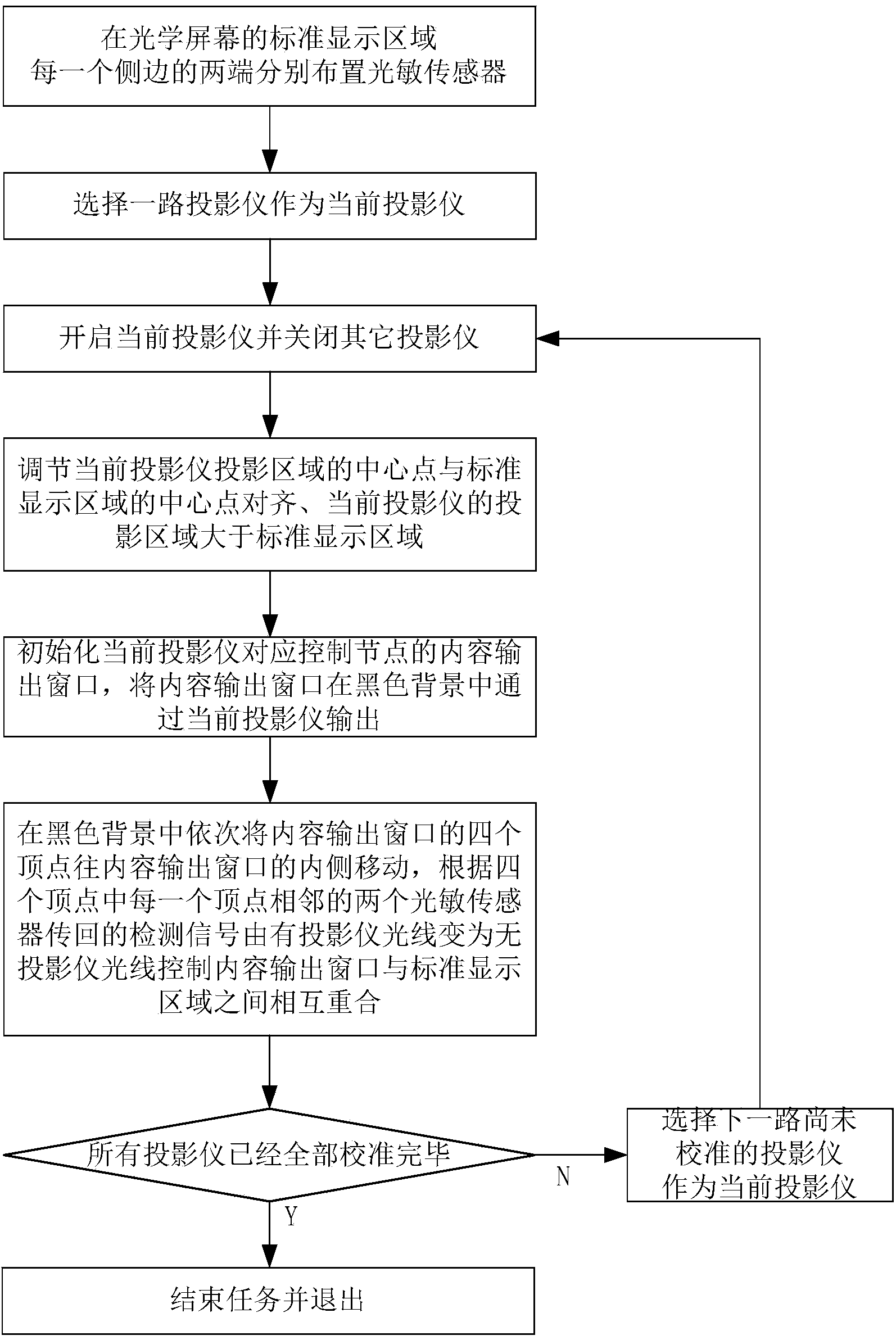

[0034] Such as image 3 As shown, the implementation steps of the output calibration method used in this embodiment for the multi-view point naked-view true three-dimensional display system are as follows:

[0035] 1) At both ends of each side of the standard display area of the optical screen, a photosensitive sensor for detecting the presence or absence of projector light is arranged respectively, and one projector is selected as the current projector.

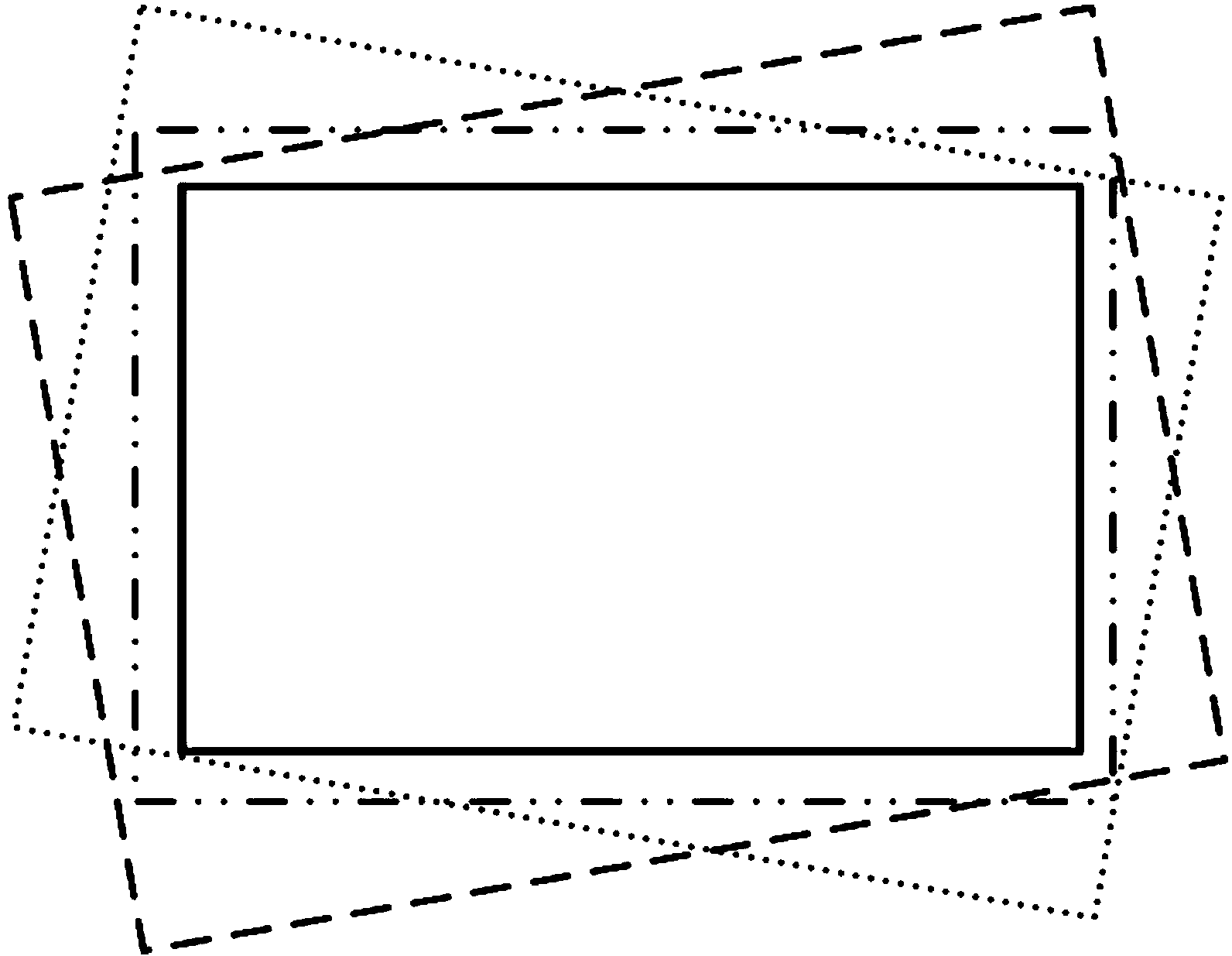

[0036] The optical screen of the multi-viewpoint naked-view true 3D display system is made of optical film. For the specific application of the multi-viewpoint naked-view true 3D display system, the size of the optical screen has been designed and the fixing device has been made. The standard display area of the multi-viewpoint stereoscopic true 3D display system can be determined on the above. Such as Figure 4 As shown, in this embodiment, a photosensitive sensor for detecting the presence or absence of projector lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com