Method and device for acoustic discrimination of multistage yield points by rock triaxial single sample method

A yield point, three-axis single technology, applied in measuring devices, scientific instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as the difficulty of sonic wave velocity testing and acoustic emission testing of rock specimens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

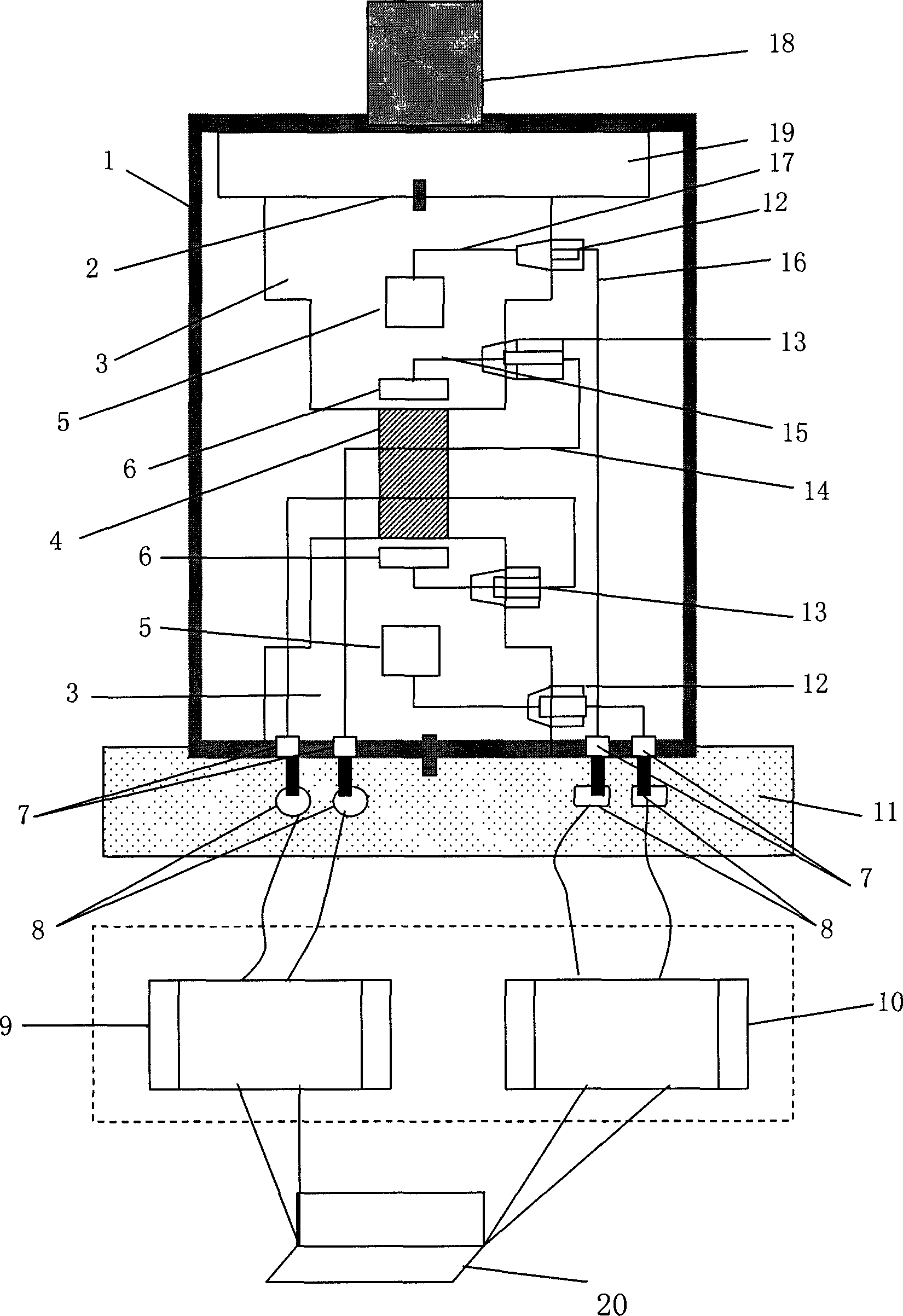

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0026] See figure 1 , an acoustic discrimination device for multi-level yield point of rock triaxial single sample method, triaxial chamber 1 is a closed container, which is filled with high oil pressure, and upper and lower ends of triaxial chamber 1 are respectively installed with upper rigid pressure The head 3 and the lower rigid indenter 3', the rock sample 4 is placed on the lower rigid indenter 3', the rock sample 4 is always placed in the triaxial chamber 1 filled with high oil pressure, and the upper rigid indenter 3 is pressed. On the rock sample 4, the upper rigid indenter 3 is provided with a pressure plate 19, and the pin 2 fixes the upper pressure plate 19 on the upper rigid indenter 3, and keeps the upper pressure plate 19 and the upper rigid indenter 3 in the center. The force transmission column 18 is arranged on the pressure plate 19, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com