Simple detection method for crack growth rate of cold-drawing high-strength steel wires

A technology of crack growth rate and high-strength steel wire, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., which can solve the problems of small material specifications, inability to process test pieces, and inability to judge the crack growth rate of cold-drawn high-strength steel wire of alternative materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

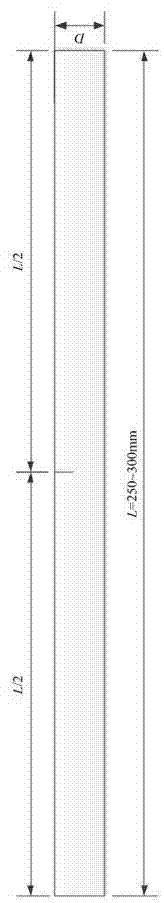

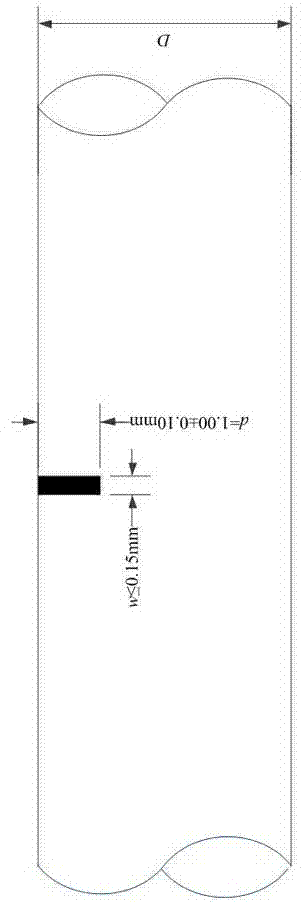

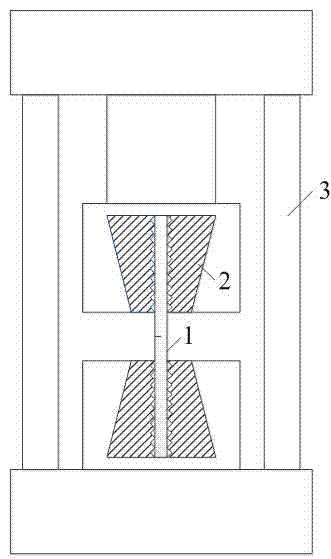

[0023] The invention relates to a method for detecting fatigue crack growth rate by using the lines formed on the steel wire fracture surface by fatigue load. Cold-drawn high-strength steel wire is a steel wire with a diameter of 5mm or 7mm obtained by cold-drawing hot-rolled steel rods for many times. During the cold drawing process, the pearlite in the steel is gradually deflected as the number of cold drawing increases, and the final high-strength steel wire is an orthotropic material whose crystal arrangement is different from that of the original hot-rolled steel rod material. Due to the small diameter of the steel wire and the curved outer surface, it is difficult to measure the crack growth length by traditional methods. The invention forms several banded lines on the steel wire crack fracture surface by applying special fatigue load, which is used for assisting the measurement of the crack length. Below in conjunction with accompanying drawing, the specific implementa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com