Gas filling system and method of high-pressure gas cylinder

A technology for high-pressure gas cylinders and gas cylinders, which is applied to container filling methods, container discharge methods, gas/liquid distribution and storage, etc., can solve problems such as damage and leakage of gas cylinders, improve filling efficiency and save manpower Cost, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

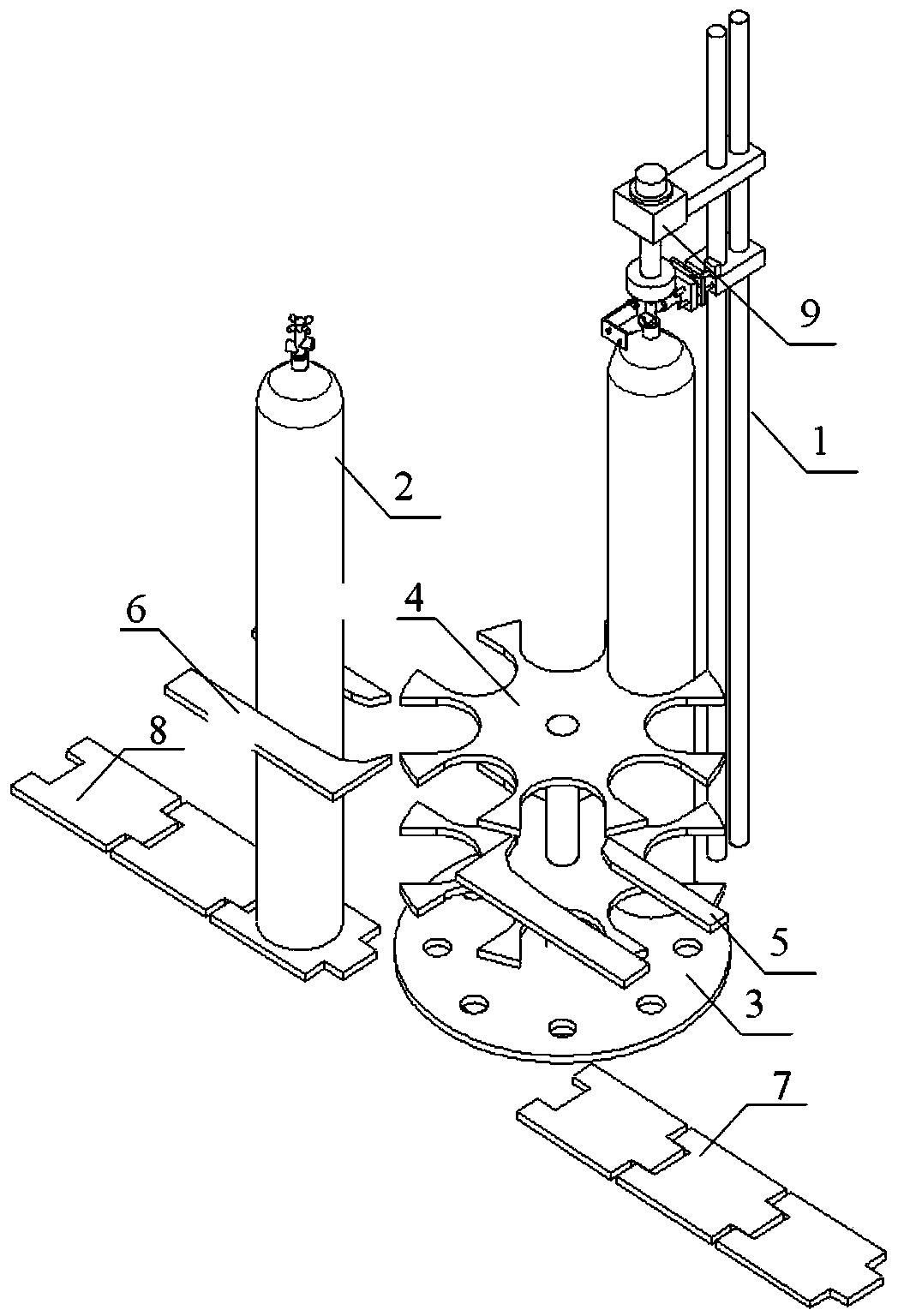

[0023] Such as figure 1 Shown: the gas filling system of the high-pressure gas cylinder 2 of the present invention includes a column 1, a gas cylinder input belt 8, an output belt 7, a bottle inlet guide plate 6 and a bottle outlet guide plate 5, a steel cylinder tray 3, and an upper indexing star wheel 4 , Inflatable device 9.

[0024] A gas filling system for high-pressure gas cylinders, mainly including a conveying device, a filling turntable, and an inflating device; The bottle guide plate, the bottle inlet guide plate is located directly above the end of the input belt, and the bottle discharge guide plate is located directly above the beginning section of the output belt; Degree star wheel, the two grooves of the upper index star wheel are respectively adjacent to the outlet end of the bottle-in and out guide plate and the inlet section of the bottle-out guide plate, and the steel cylinder tray is adjacent to the bottle-out end of the input belt and the bottle-in end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com