Parallel-tube snubbing pulverized coal discharging system for coal-bed gas well

A technology of coalbed methane wells and parallel pipes, which is applied in the direction of wellbore/well components, flushing wellbore, production fluid, etc. It can solve problems affecting the recovery of coalbed methane well productivity, polluted coal seams, and velocity-sensitive effects, so as to avoid velocity-sensitivity and Pressure-sensitive phenomena, ensuring operation safety, and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

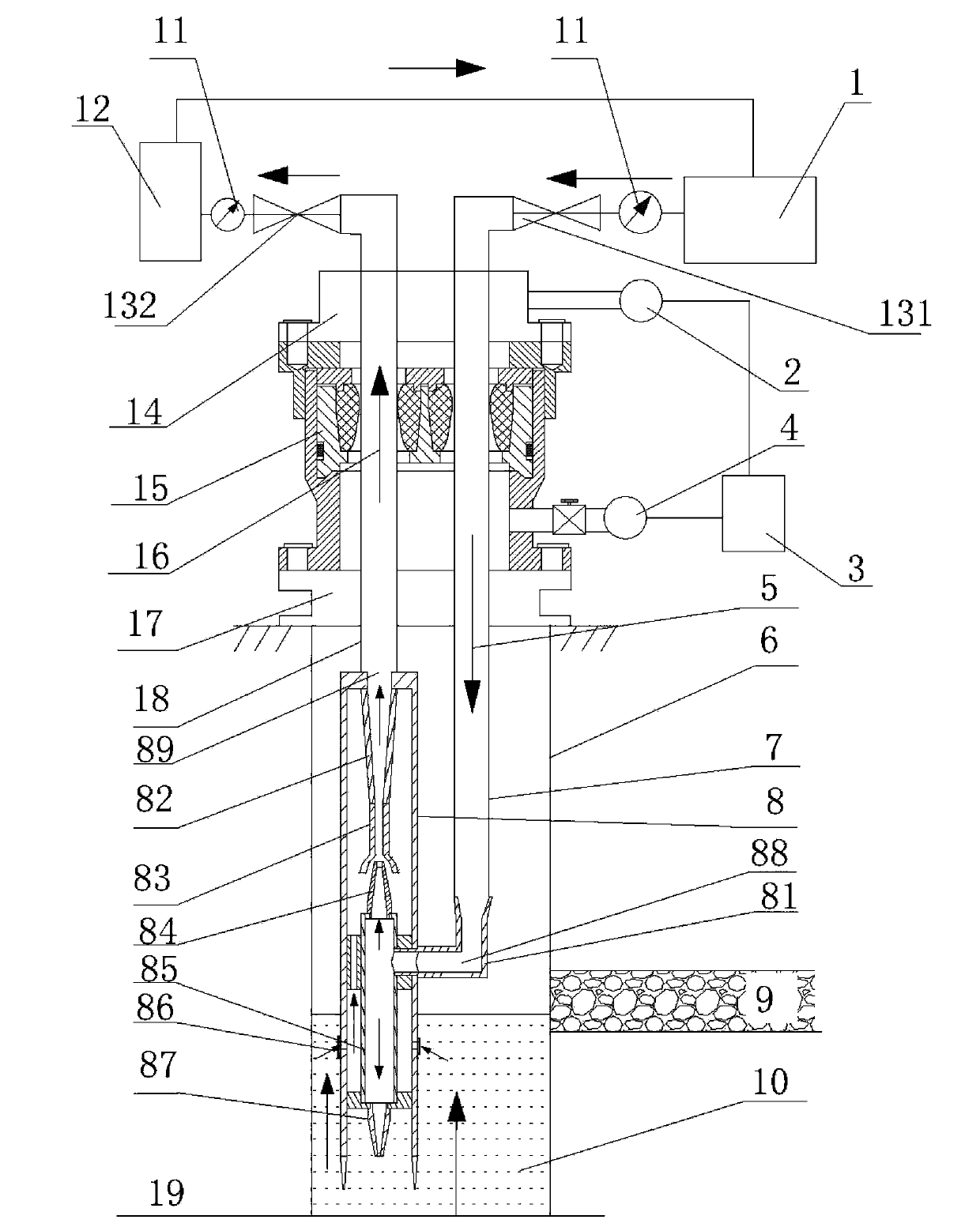

[0029] This embodiment provides a pulverized coal discharge system for a parallel pipe string of a coalbed methane well, see figure 1 , figure 2 and image 3The system includes: a ground part installed on the surface of the wellhead of the operation well and a downhole part installed under the operation well. Wherein, the ground part is the control mechanism of the coalbed methane well concentric pipe pulverized coal discharge system, and the downhole part is the executive mechanism of the coalbed methane well concentric pipe pulverized coal discharge system.

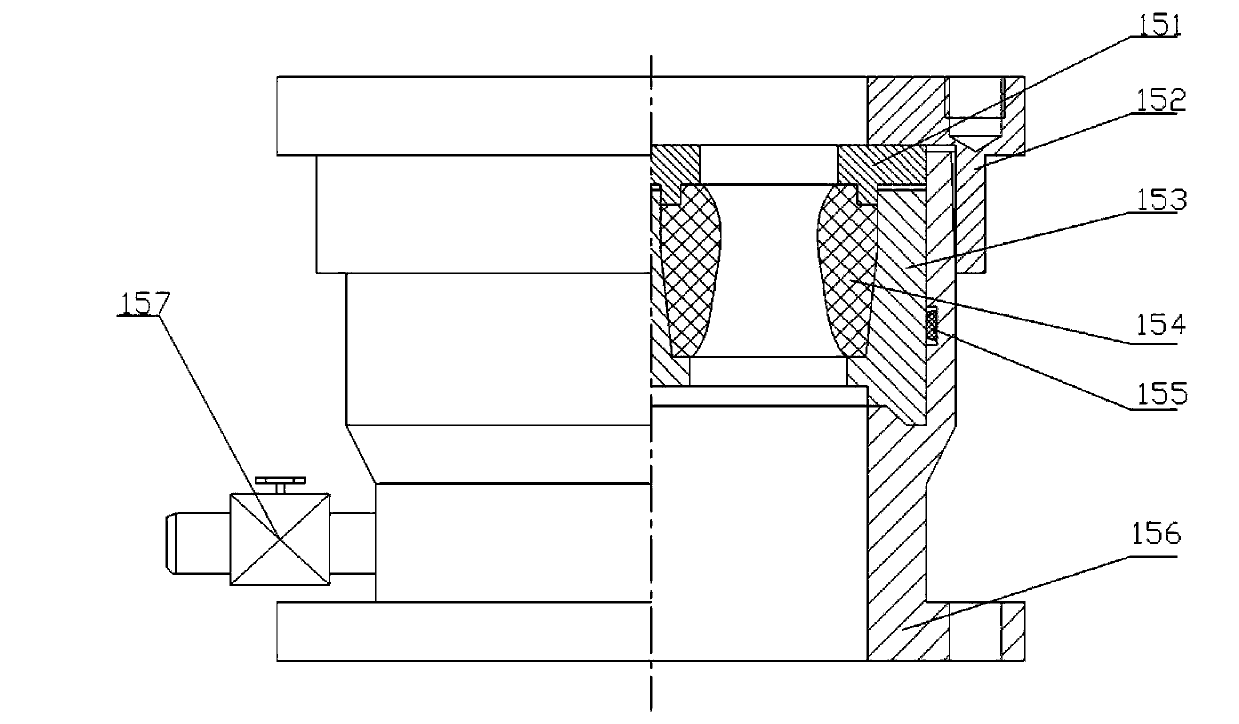

[0030] Specifically, the ground part includes a solid-liquid separation device 12 , a pump truck 1 , a parallel tube self-sealing device 15 , a parallel tube wellhead device 14 , a blower 2 and a coalbed methane recovery device 3 . Among them, the solid-liquid separation device 12 separates the muddy material mixed with coal powder and high-pressure water discharged from the well, discharges or recovers the coal powd...

Embodiment 2

[0042] This embodiment provides a coal bed methane well parallel pipe snub-free method for discharging pulverized coal, using the coal bed methane well parallel pipe string discharging pulverized coal system described in Embodiment 1, and the specific steps of the method are:

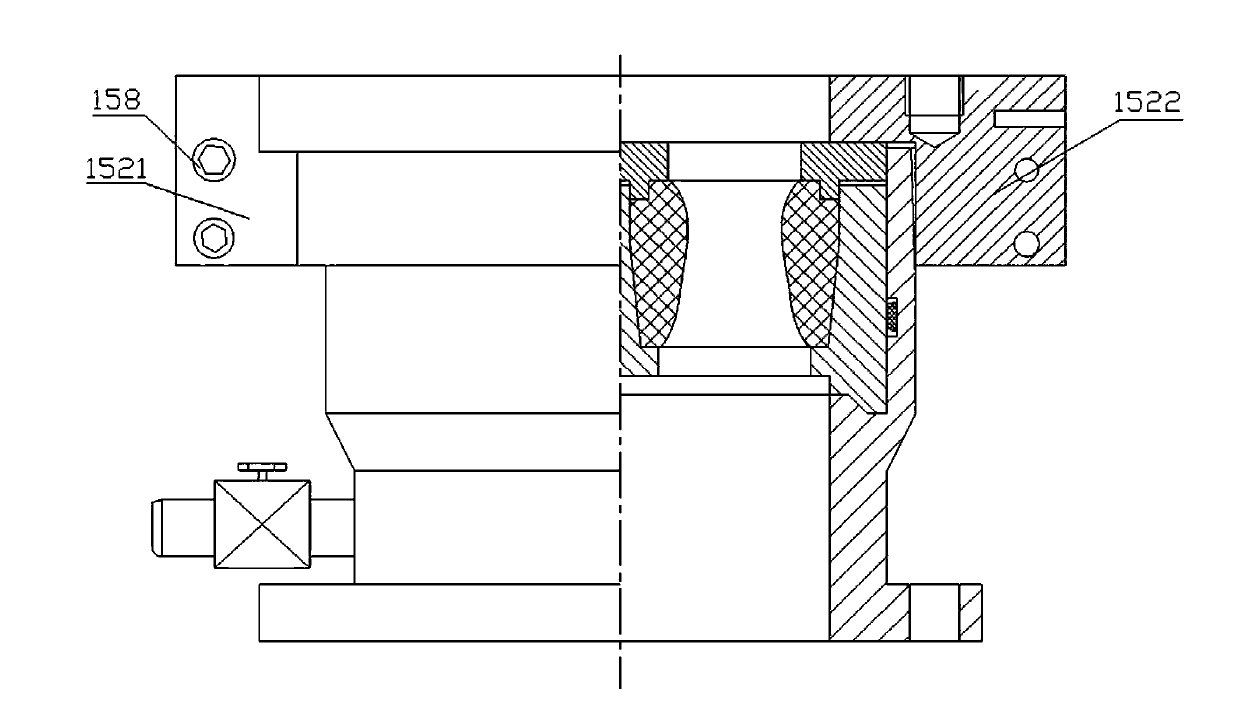

[0043] S1, determine the operation well, install the casing 156 and the top cover 152 in the parallel pipe self-sealing device 15 at the wellhead of the operation well, and connect the first oil pipe 7 and the second oil pipe 18 to the parallel pipe hydraulic jet flushing pulverized coal device 8 respectively Connect the first oil pipe 7 and the second oil pipe 18 with the parallel pipe hydraulic jet flushing pulverized coal device 8 through the top cover 152 and the casing 156 and lower them into the operation well, then lift the top cover 152 and put the two bushings 153 Put it into the casing 156, place the two opening sealing rubbers 154 in the cavity formed by the two bushings 153 respectively, inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com