Electric pole centralizer

A technology of centralizers and electric poles, applied in building types, buildings, towers, etc., can solve the problems of shovel digging difficulty, low efficiency, high labor intensity, etc., to reduce the price and operation difficulty, simple structure, and enhance versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

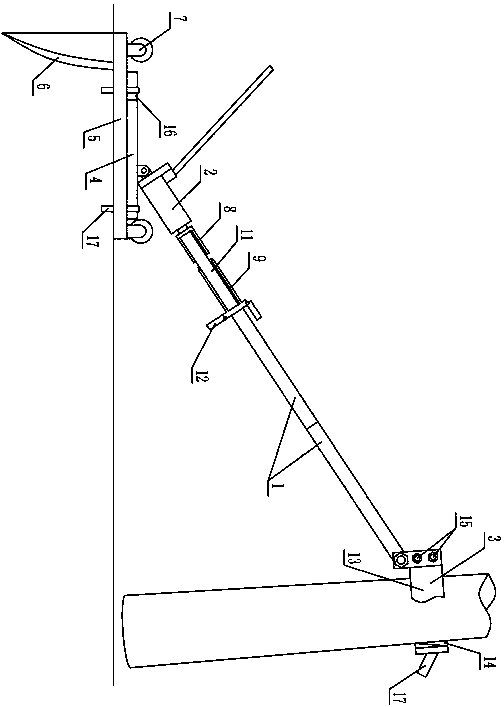

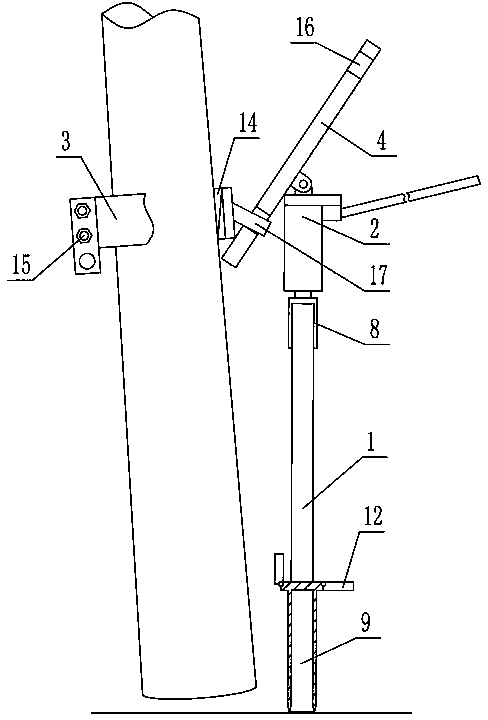

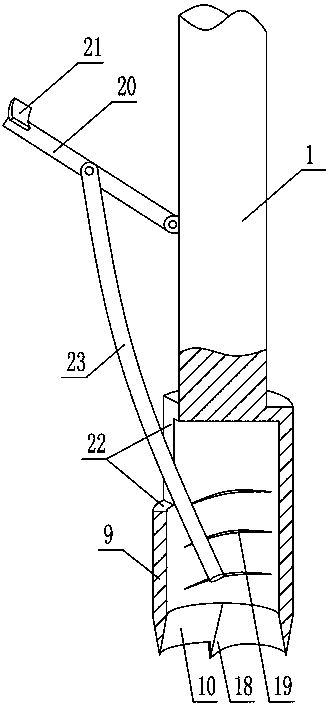

[0037] As shown in the figure, the pole centralizer includes a plurality of multifunctional components, and each multifunctional component is connected through different combinations or assembly methods, thereby realizing different functions. The so-called multifunctional component means that the component has more than one function or function in the pole centralizer, and different combinations of each multifunctional component can realize different functions. Specifically, the pole centralizer mainly includes a clamp 3 , a support rod 1 , a jack 2 and a base 5 connected in sequence. In the pole centralizer, the clamp 3, the support rod 1, the jack 2 and the base 5 all belong to multifunctional components. The clamp 3, the support rod 1, the jack 2 and the base 5 can realize different functions through different combinations or connection methods. In this electric pole centralizer, the different functions realized by the clamp 3, the support rod 1, the jack 2 and the base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com