Deep water silt layer geological large-span multi-line reinforcing system and jacking culvert construction method

A construction method and technology of silt layer, applied in erecting/assembling bridges, bridges, buildings, etc., can solve the problems of underground water gushing, unstable foundation, short railway interference time, etc., and achieve convenient reinforcement and installation, easy operation, and earthquake resistance The effect of good performance and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

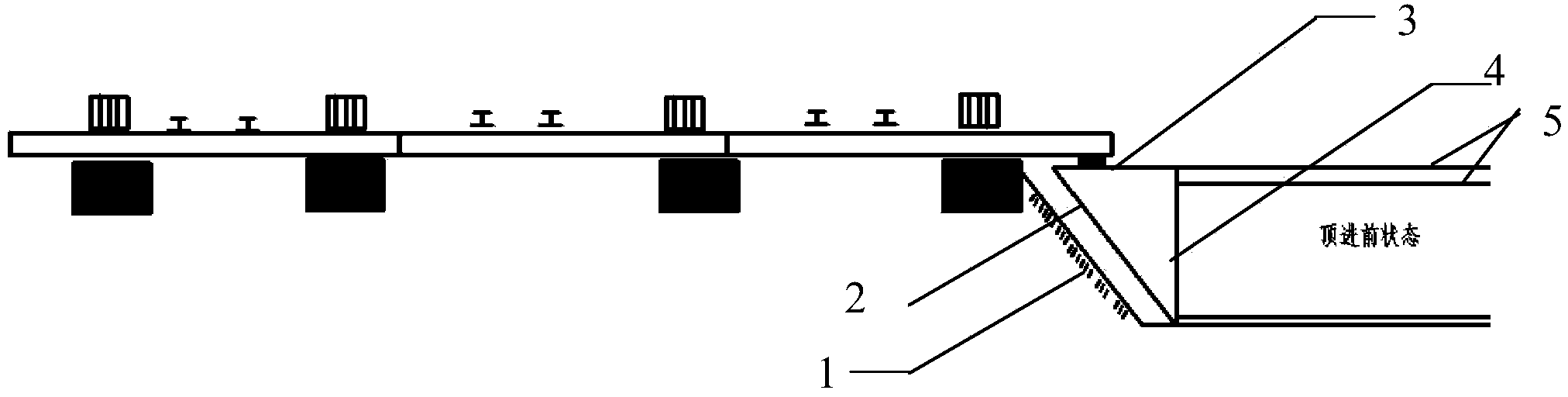

[0021] Such as figure 1 As shown, a deep-water silt layer geological long-span multi-line reinforcement system includes a high-pressure rotary grouting occlusal pile 1, a protective pile 2, an anti-sway pile 3, and a support pile 4. The high-pressure rotary grouting occlusal piles are arranged at the entrance and exit of the frame bridge to reinforce the slope and the bottom of the foundation pit; the top of the protective piles is provided with a reinforced concrete crown beam 5 as a hard fulcrum for reinforcing the I-beam beam on the outer side of the bridge The anti-sway pile is the front back beam when the bridge is jacked, which can effectively prevent the line from moving laterally during the jacking of the bridge; The hard fulcrum of the beam, even if a collapse occurs, the I-beam of the beam can lift the line through the action of the supporting pile longitudinal beam, which does not affect the driving safety of the line, and can effectively prevent the collapse of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com