SAPO-34 molecular sieve with diisopropanolamine as template, and its synthetic method

A technology of SAPO-34 and diisopropanolamine, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of limited reserves of petroleum resources, unstable supply, rising prices, etc., and achieve excellent Catalytic performance, good selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

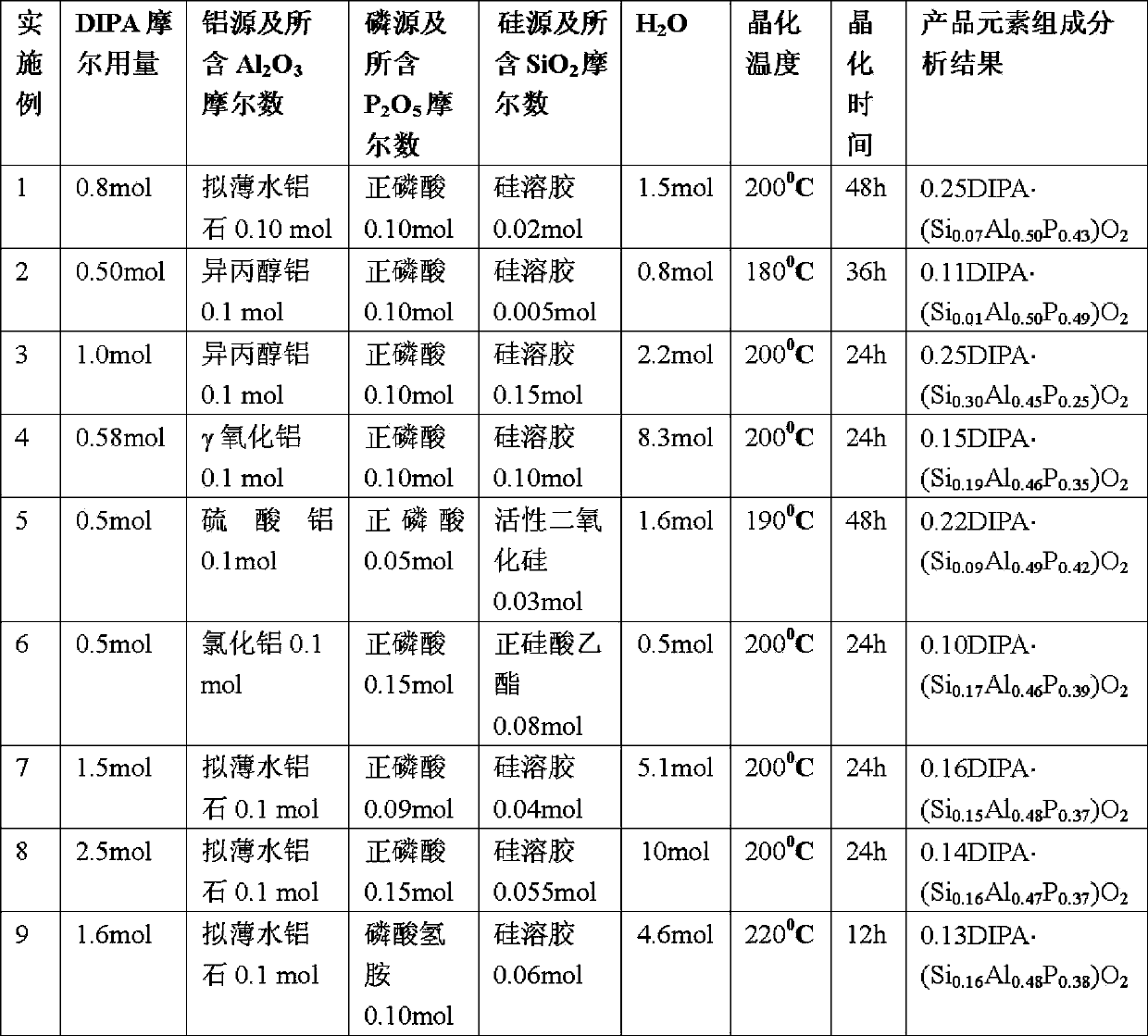

[0042] The molar proportions of each raw material, crystallization conditions and elemental composition of the samples are shown in Table 1. The specific batching process is as follows, 42.5g diisopropanolamine and 7.1g deionized water are mixed and stirred evenly, then add 5.6g pseudoboehmite (Al 2 o 3 Mass percentage composition 72.5%) stir evenly, then 9.12g phosphoric acid (H 3 PO 4 mass percent content 85%) dropwise into, stir evenly, finally add 1.59g silica sol (SiO 2 mass percentage 30.34%), stirred evenly to make a gel, and the gel was transferred to a stainless steel reaction kettle. The molar ratio of each component in the synthesis system is 8.0DIPA:0.20SiO 2 : 1Al 2 o 3 : 1P 2 o 5 : 15H 2 O.

[0043] After putting the reaction kettle into the oven, the temperature was programmed to 200°C for dynamic crystallization for 48 hours. After the crystallization, the solid product was centrifuged, washed, and dried in air at 100°C to obtain the original powder....

Embodiment 2-19

[0051] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as in Example 1.

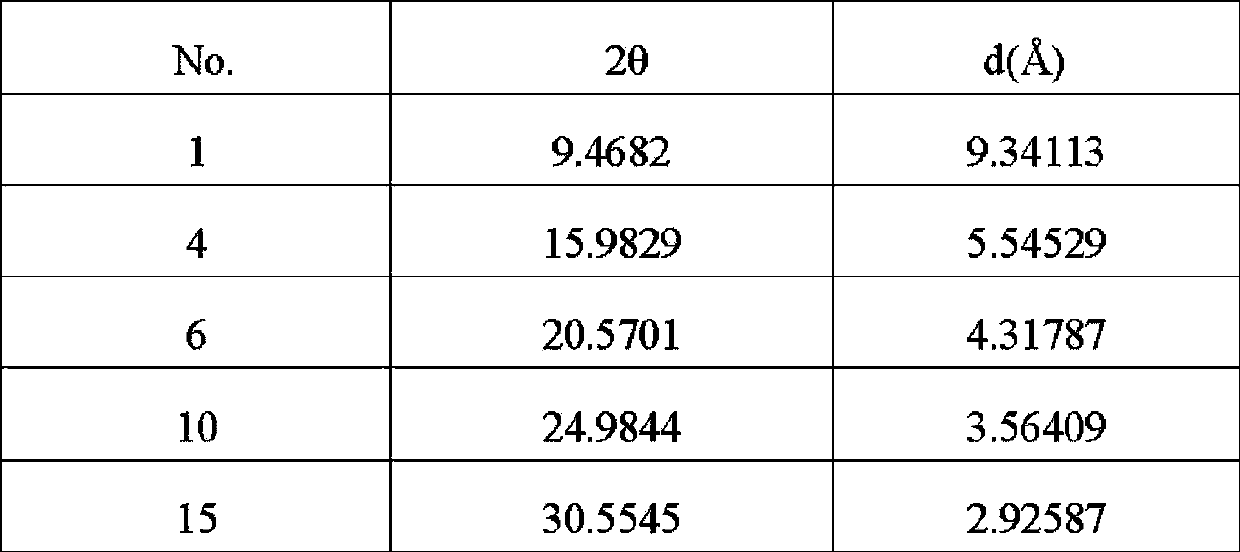

[0052] Synthetic samples were analyzed by XRD, and the data results were close to those in Table 2, that is, the peak positions and shapes were the same, and the relative peak intensity of the peaks fluctuated in the range of ±10% according to the change of the synthesis conditions, indicating that the synthetic products had the characteristics of the SAPO-34 structure. The results of elemental composition analysis of the product are shown in Table 1.

[0053] Carry out to the former powder sample of embodiment 1-10 13 C MAS NMR analysis by diisopropanolamine 13 The C MAS NMR standard spectrum was compared, and it was found that only the resonance peak of diisopropanolamine was found in the sample.

Embodiment 20

[0055] The sample obtained in Example 1 was calcined at 550° C. for 4 hours, and then pressed into tablets and crushed to 20-40 meshes. Weigh 5.0 g of the sample and put it into a tank reactor filled with 30 ml of ethanol to carry out ethanol dehydration reaction. The reaction temperature was set at 150° C., and the reaction was carried out under stirring. The reaction results show that the conversion rate of ethanol can reach 90%, and the selectivity of ether in the product is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com