A friction all-drive eight-wheel tractor

A tractor and friction wheel technology, applied in the field of tractors, can solve the problems of complex operation process, low efficiency, difficult steering, etc., and achieve the effect of reducing transition costs and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

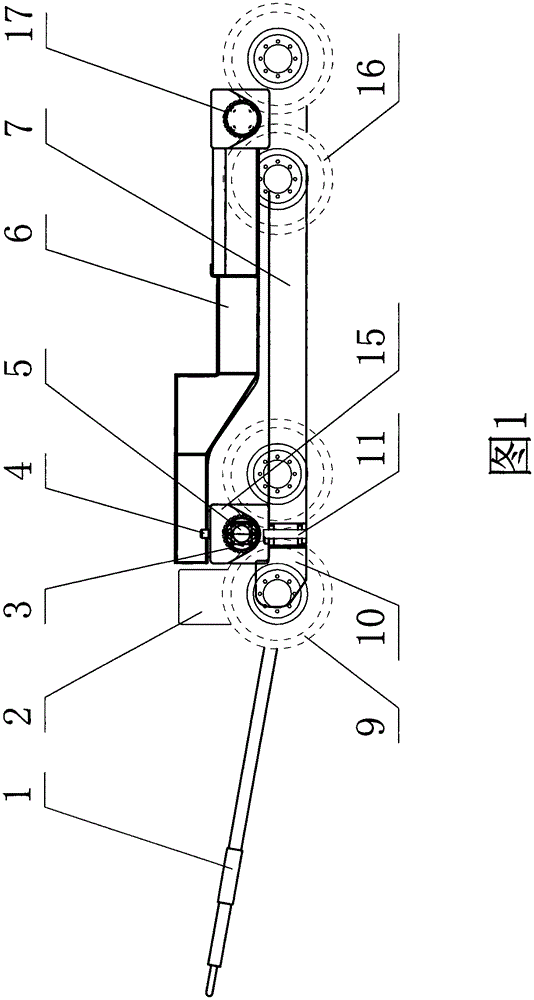

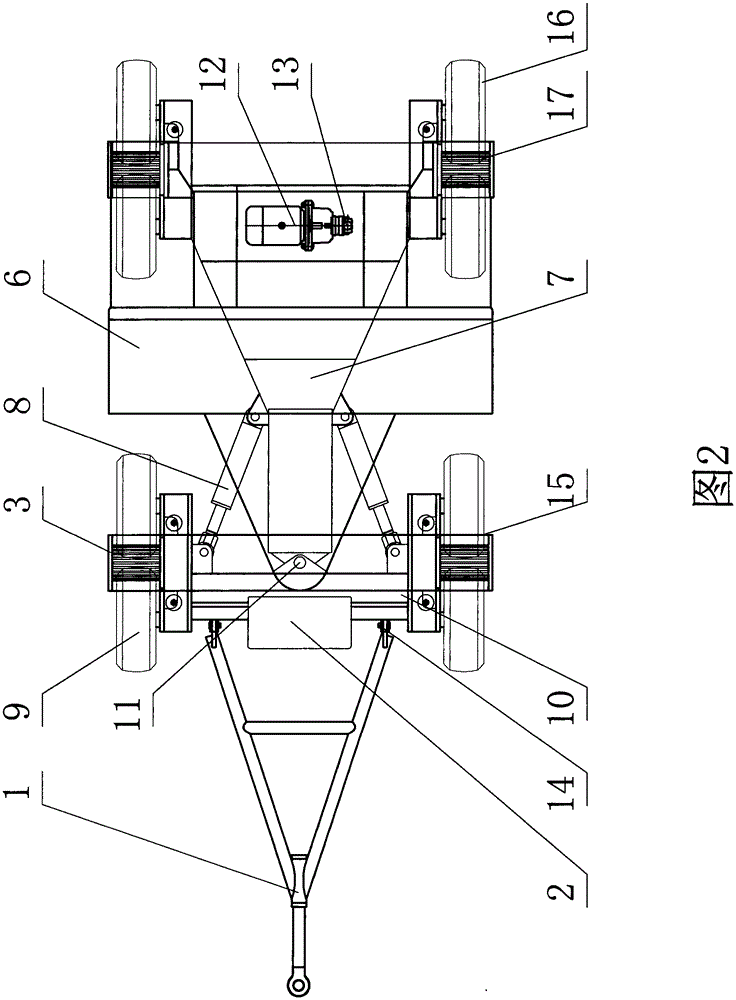

[0017] Attached below figure 1 , 2 A kind of friction all-drive eight-wheel tractor of the present invention is described in detail below.

[0018] as attached figure 1 , 2 As shown, a kind of friction all-drive eight-wheel tractor of the present invention, its structure comprises drawbar 1, lower bracket assembly and upper vehicle frame assembly, and described lower bracket assembly includes the lower front bracket assembly of split design and the lower rear bracket Assembling, the lower front bracket assembly includes the lower front bracket 10 and two left and right front road wheels 9 arranged on it;

[0019] The upper frame assembly includes split-designed upper front frame assembly and upper rear frame assembly, the upper front frame assembly includes upper front frame 15 and left and right front friction wheels 3 arranged thereon, each The front friction wheel 3 is provided with a hydraulic motor 5, and the upper front frame 15 is lapped on the front running wheel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com