Multi-section swing arm crawler-type robot for detection of mine disasters

A crawler and robot technology, applied in the field of robotics, can solve the problems of low height of vertical obstacles for swing-arm robots, low performance of single-section robots over continuous obstacles, and insufficient power, and achieve light and convenient pitching and yawing. Navigation, simple and practical design, power-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

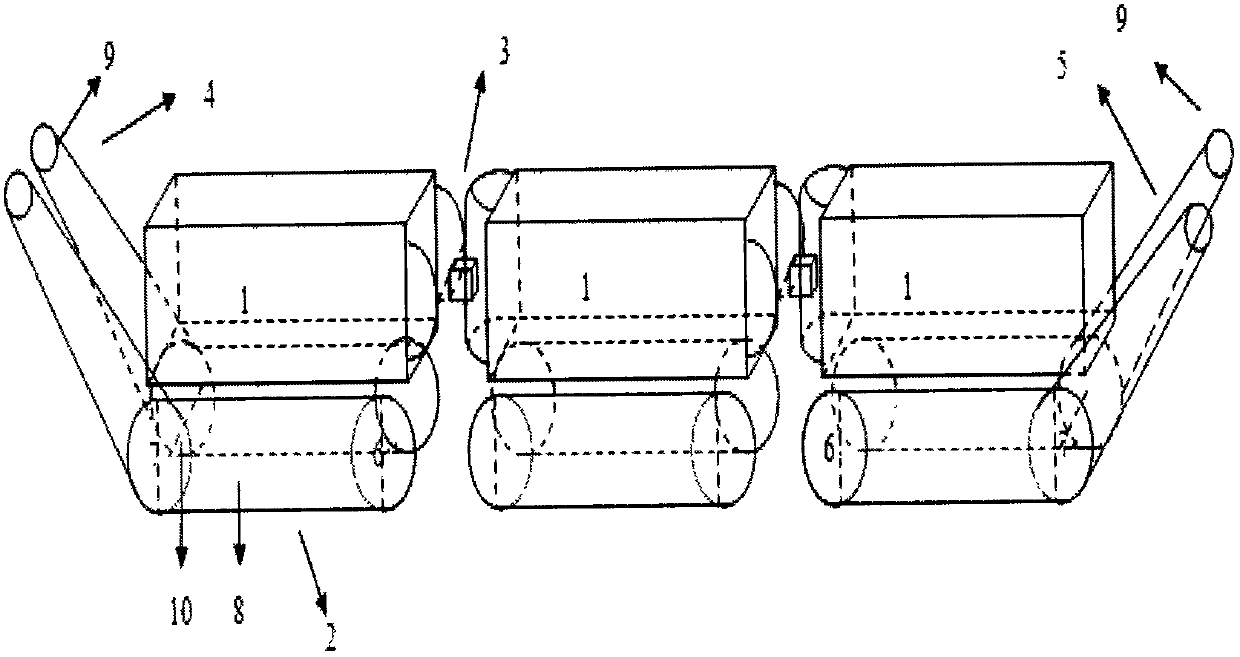

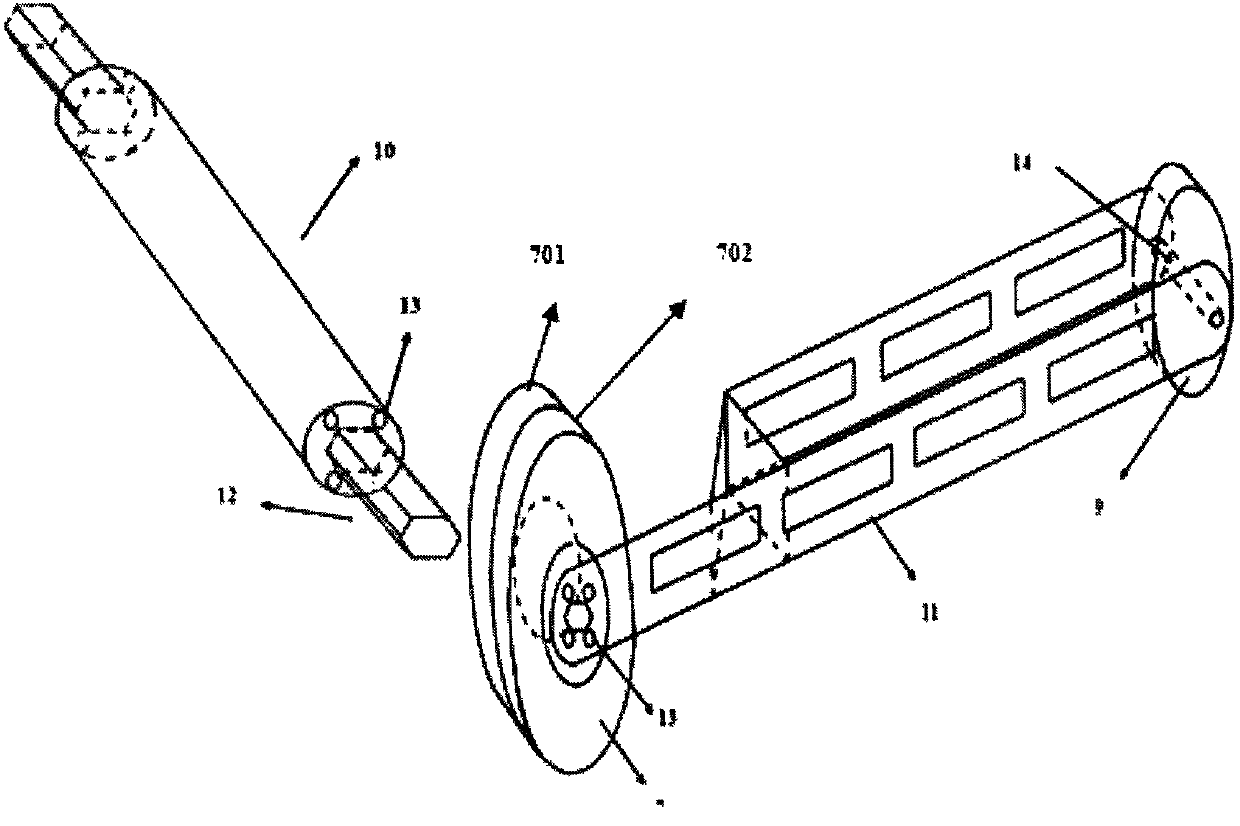

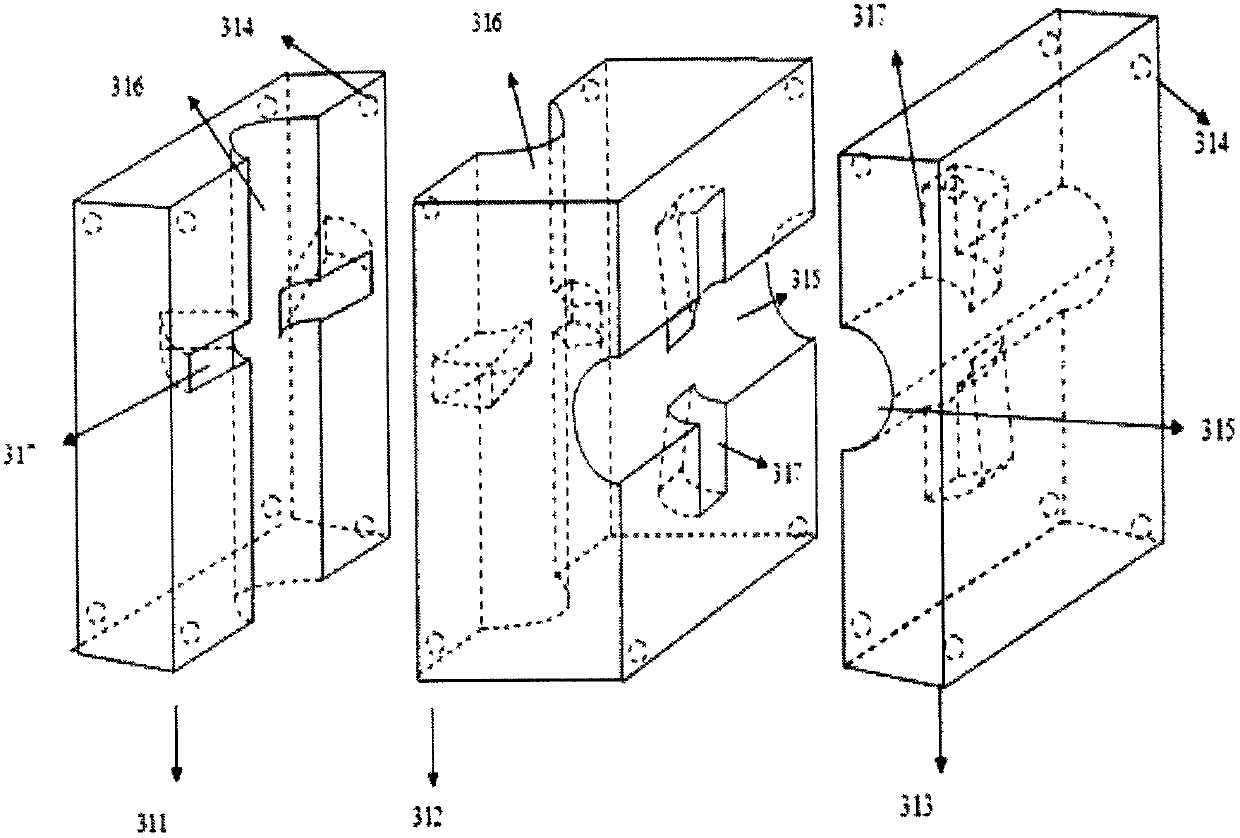

[0020] Combine below figure 1 , figure 2 , image 3 , Figure 4 Specific embodiments of the present invention are described in detail.

[0021] from figure 1 It can be seen that the overall structure of the multi-section swing arm crawler mine disaster detection robot. The robot is formed by connecting three car bodies 1 through special joint modules 3, adopts a crawler-type walking mechanism 2, and the first and last two car bodies are respectively equipped with crawler-type swing arm units. The three car bodies have independent crawler running mechanisms. The positions of the driving wheels 6 of the crawler running mechanisms of the first and last two car bodies are different. The driving wheel of the first car body is the rear wheel, and the driving wheel of the last car body is the front wheel. The crawlers on both sides of the last two car bodies can be controlled independently, and the steering of the car body can be realized by using the differential speed. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com