Remote manual driveshaft center bearing height adjustment mechanisms

A technology of height adjustment mechanism and drive shaft, which is applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems of difficult access for users and ineffective position of the drive shaft, and achieve the effect of improving ride comfort and maneuvering flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

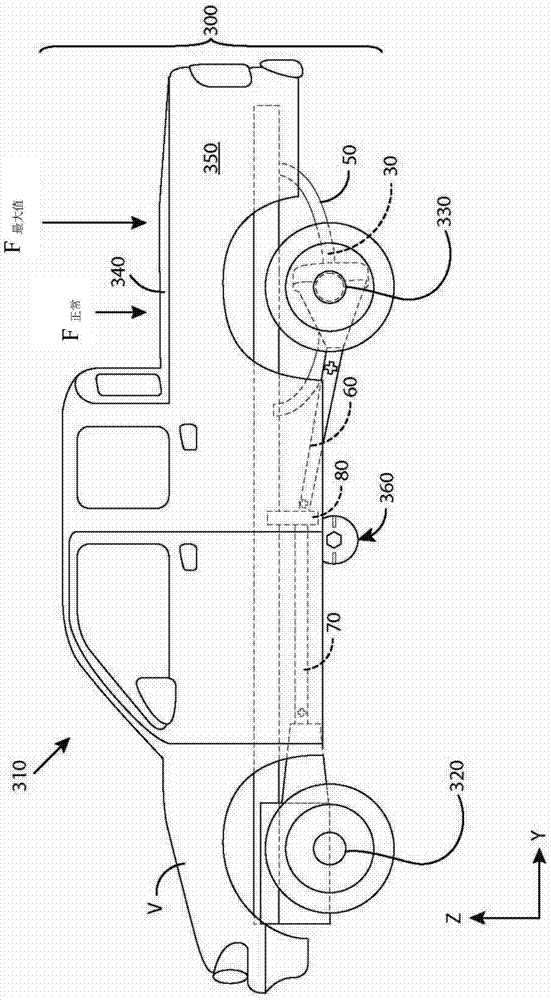

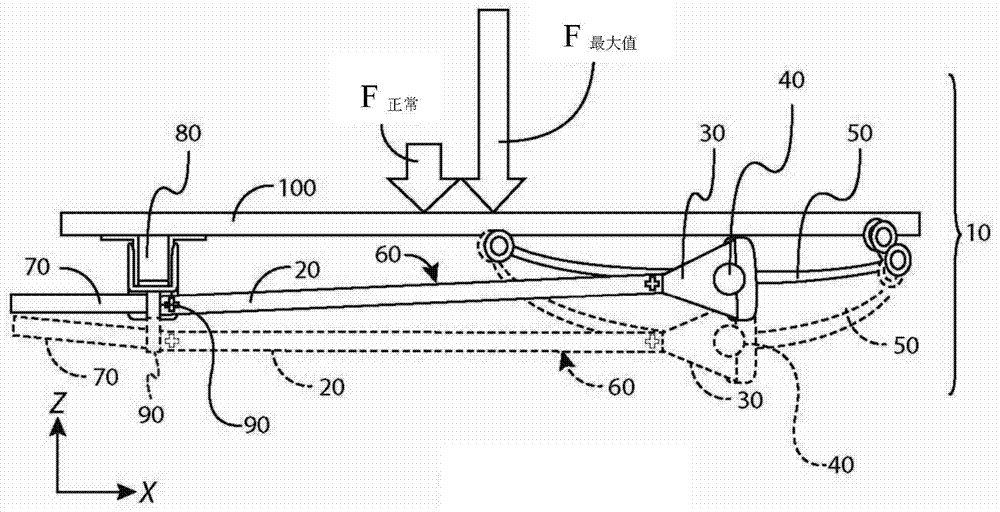

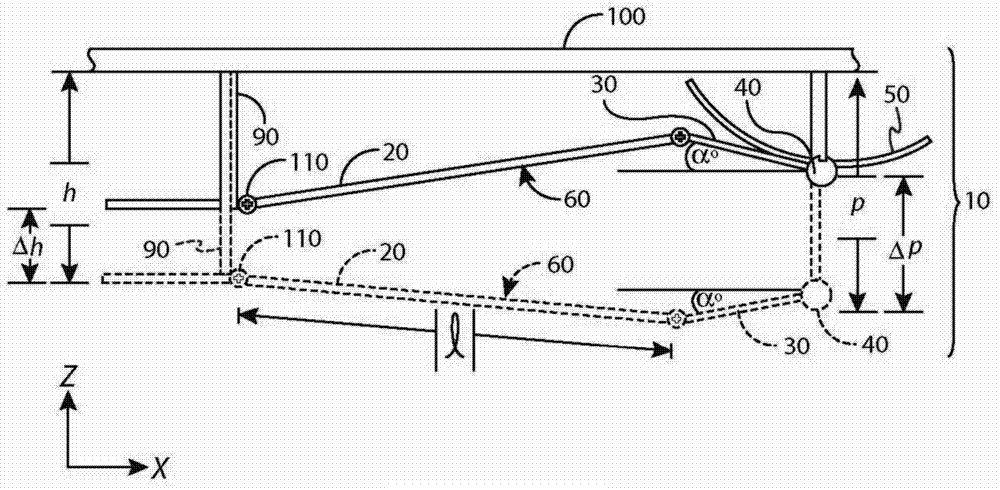

Embodiment Construction

[0024] Referring to the drawings, there is shown an exemplary height adjustment mechanism (or "HAM") for a vehicle propshaft, wherein like features represent examples of like or corresponding parts throughout the several views. The illustrated HAM provides a propshaft manual selector set based on vehicle load conditions. The driver may actuate a manual user input device (eg, a lever) to select the height of the drive shaft center bearing bracket. The predetermined positions provide optimum driveline angles for specific load conditions. The manual user input device is positioned remotely from the propeller shaft and the mounting device for the propeller shaft. The manual user input device is thus remotely located relative to the propshaft mounting arrangement while being convenient for the driver to use. For example, in the illustrated embodiment, the manual user input device is located on the side of the vehicle, bonded to the body sheet metal at knee height.

[0025] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com