Mould pressing device and method of composite material

A composite material and molding technology, which is applied in the field of composite material molding equipment, can solve the problems of low product yield, prone to bubbles on the product surface, poor exhaust, etc., and achieve the effect of high gloss on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

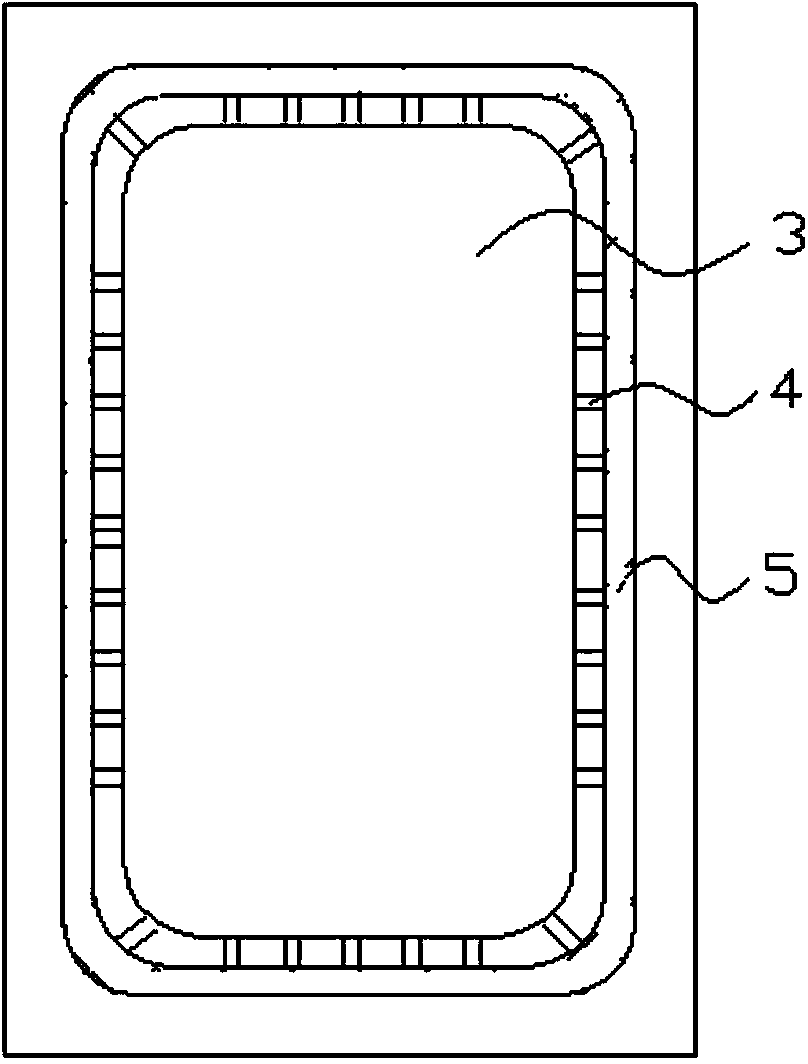

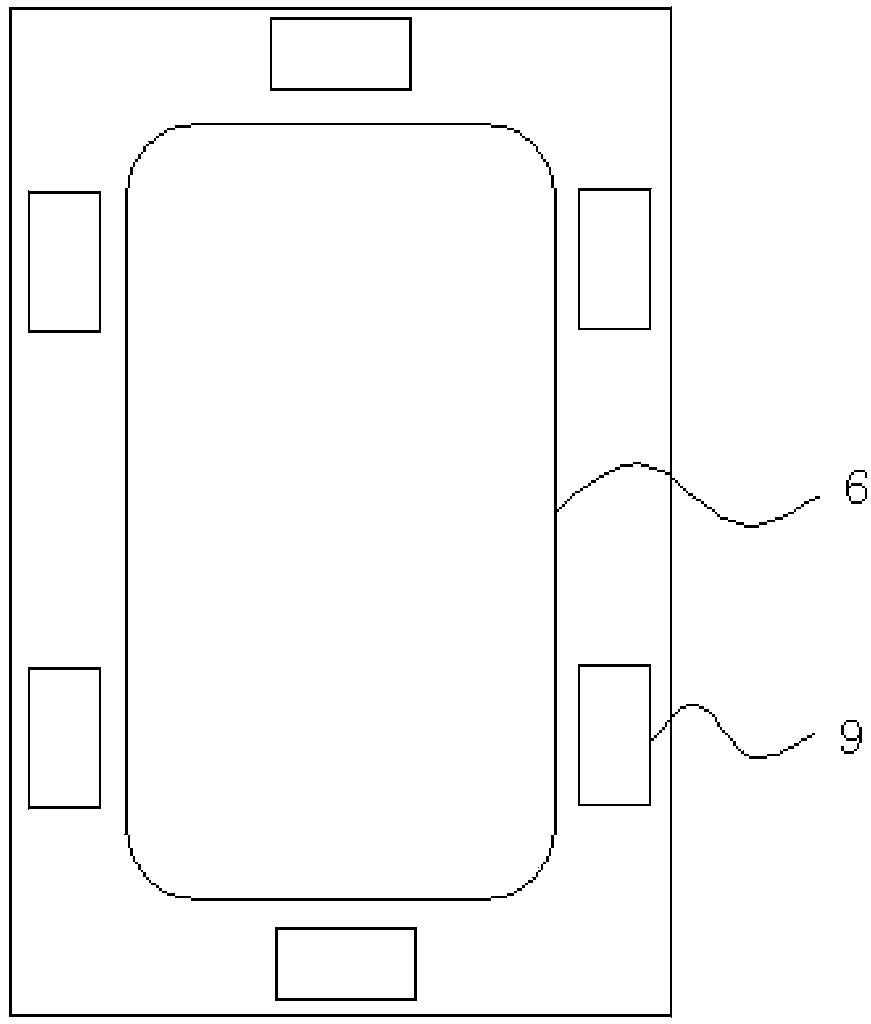

Method used

Image

Examples

example 1

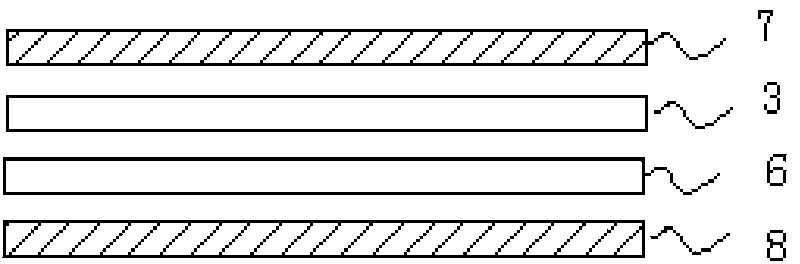

[0047] 1) The fiber prepreg is cut, and the cutting direction is 45°. It is cut according to the product specification, and the edge part is 0.8cm longer than the product specification. The interlayer arrangement of the fiber prepreg fabric is staggered, which is a layer of twill bidirectional weave fabric, a layer of unidirectional fabric and a layer of plain weave bidirectional fabric, and the thickness of the fabric is 0.6mm.

[0048] 2) Clean the mold with carbon fiber cleaning agent and mold release agent, put it on the hot plate and heat it to 60°C, the detergent will evaporate, then apply the mold release agent, dry for 10 seconds, a film will form on the surface of the mold, and then spread cloth, flatten the cloth.

[0049] 3) Heating and pressing once, the temperature rises to 80°C, and the pressure rises to 2kgf / cm 2 .

[0050] 4) Constant temperature for 100s, control the opening and closing of the hot platen for exhausting, the number of exhausting times is 4 ti...

example 2

[0057] 1) The fiber prepreg is cut, and the cutting direction is 90°. It is cut according to the product specification, and the edge part is 0.8cm longer than the product specification. The layers of fiber prepreg are staggered, and the arrangement is 3 layers of twill bidirectional weave fabric + 5 layers of unidirectional fabric, and the thickness of the fabric is 1.25mm.

[0058] 2) Clean the mold with carbon fiber cleaning agent and mold release agent, put it on the hot plate and heat it to 60°C, the detergent will evaporate, then apply the mold release agent, dry for 10 seconds, a film will form on the surface of the mold, and then spread cloth, flatten the cloth.

[0059] 3) Heating and pressing once, the temperature rises to 85°C, and the pressure rises to 2kgf / cm 2 ,

[0060] 4) When the mold reaches the temperature, keep the temperature constant for 120s, control the opening and closing of the hot platen for exhausting, the number of exhausting times is 8 times, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com