Angle grinder with push rod type stopping mechanism

A stop mechanism and angle grinder technology, which is applied to portable grinding machines, grinders, manufacturing tools, etc., can solve the problems of limiting the range of use of the angle grinder, inconvenient operation, and large volume occupied by the stop pin structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

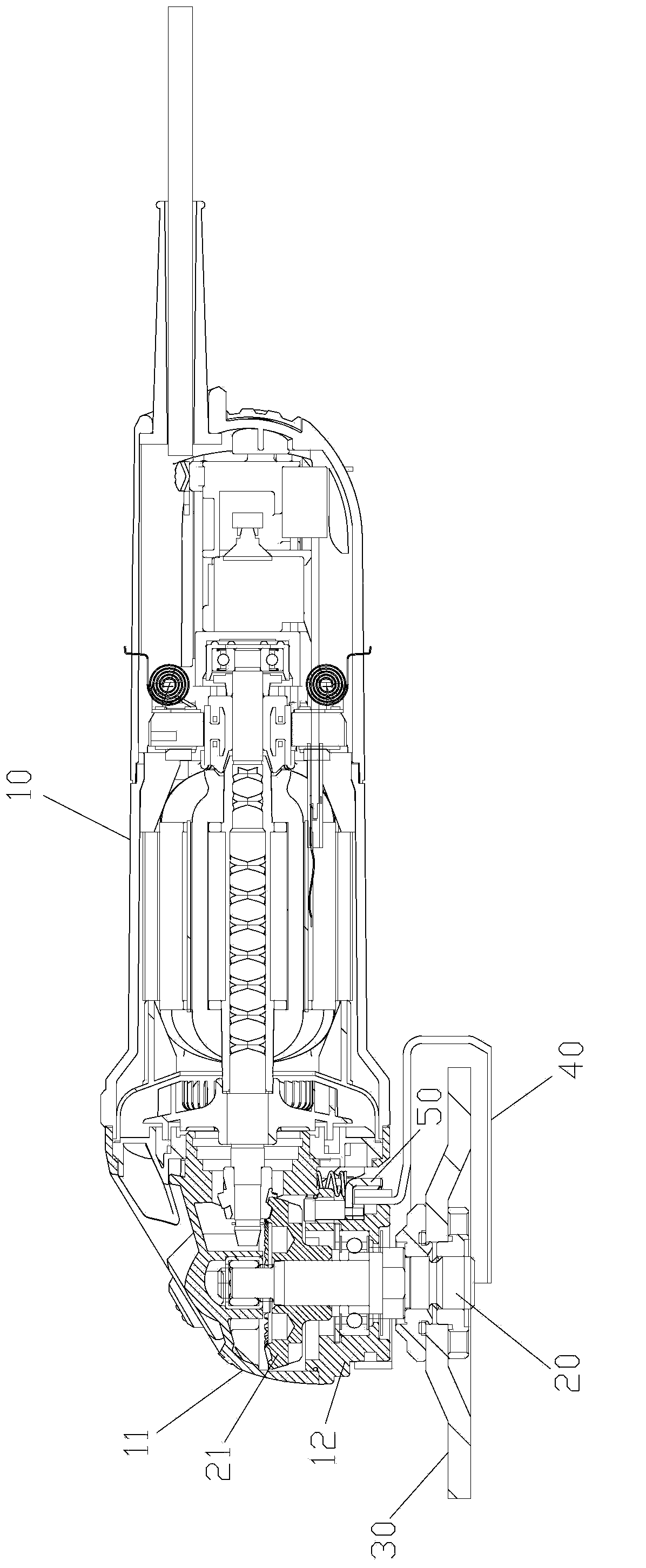

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

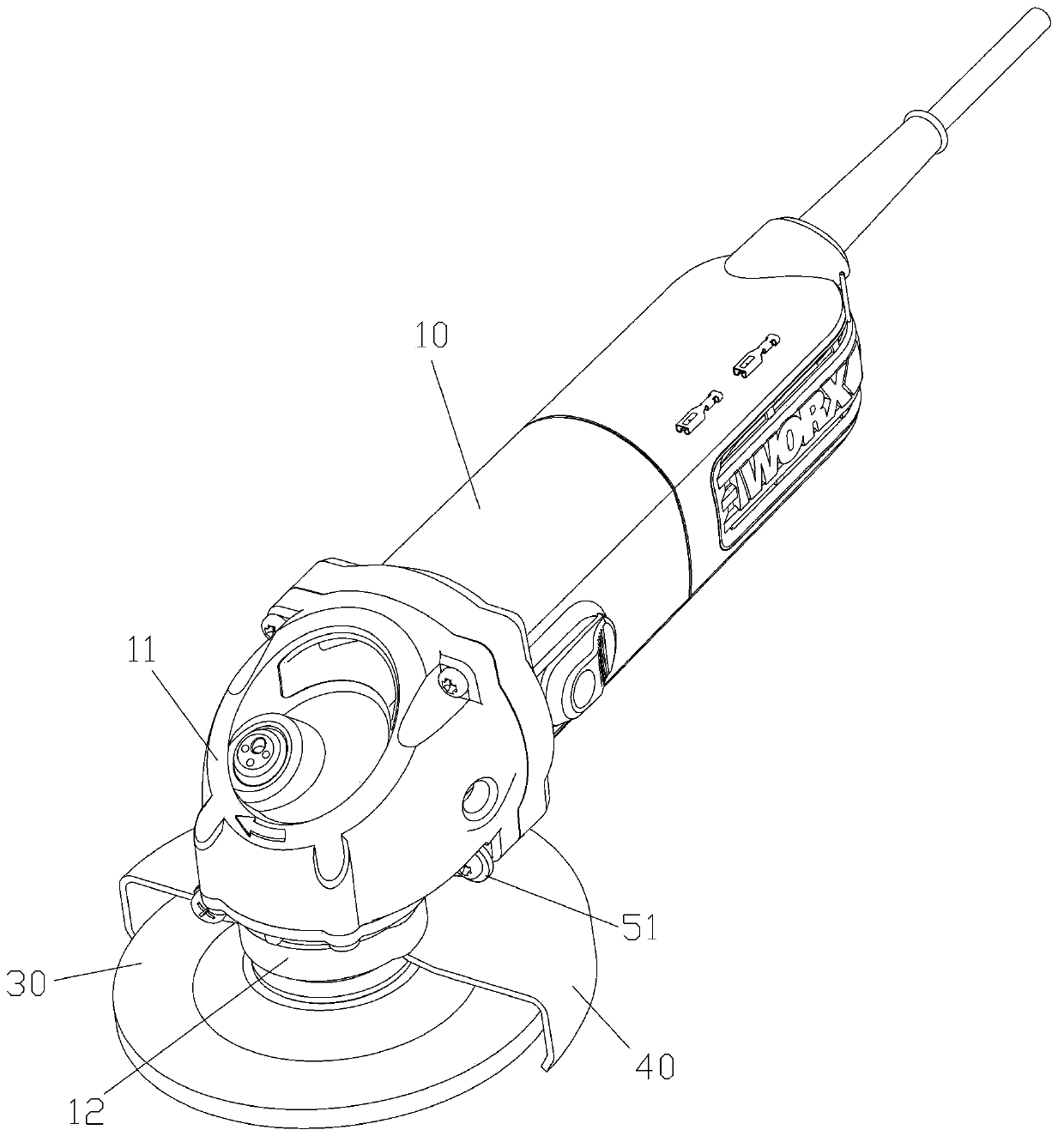

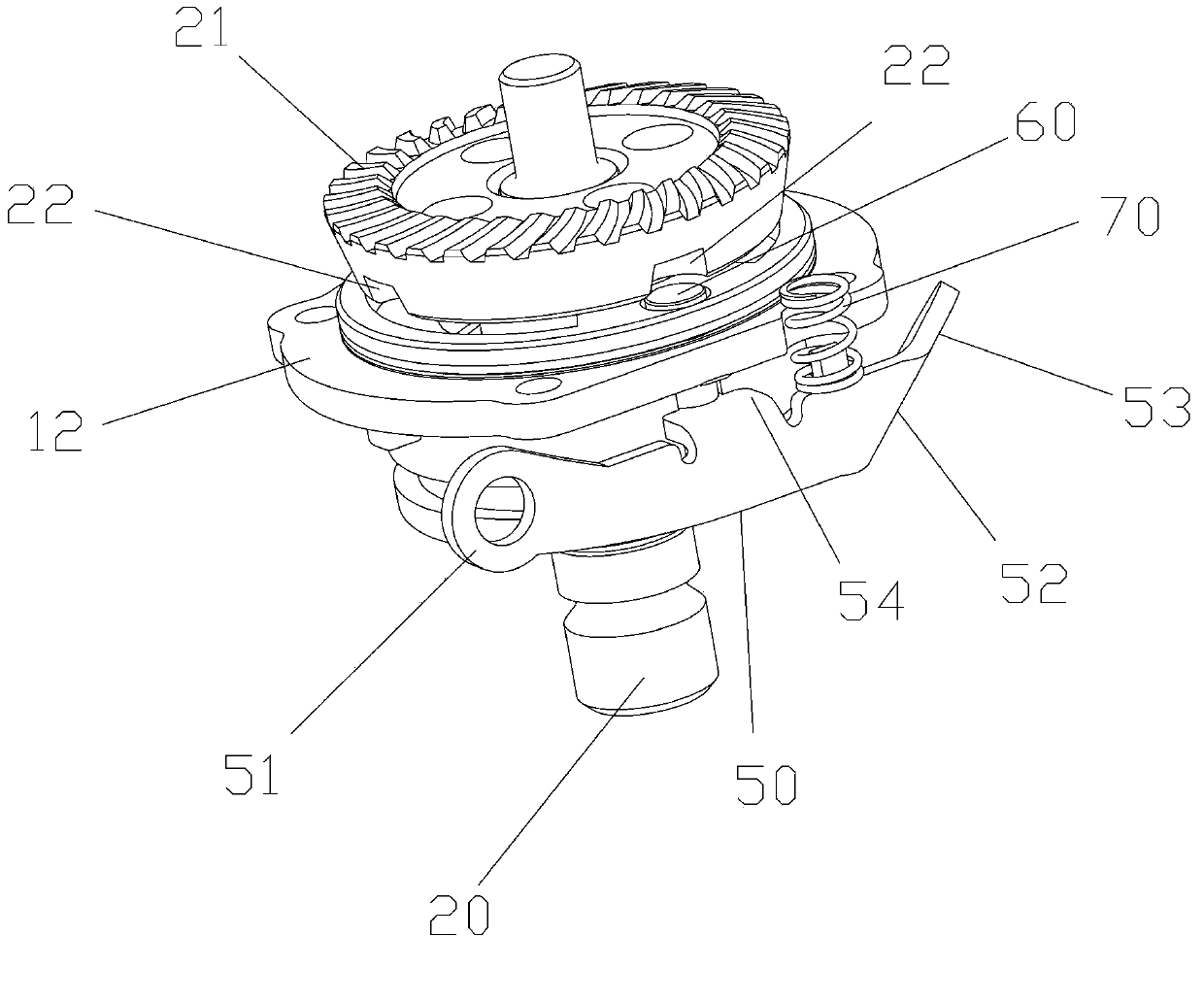

[0020] see Figure 1 to Figure 5 , the present invention provides an angle grinder with a push rod type stop mechanism, which includes an angle grinder body 10, a head shell 11, an output shaft 20 mounted on the head shell 11, and a drive for driving the output shaft 20 The gear 21 , the gear box cover 12 installed on the lower part of the head shell 11 , the grinding wheel sheet 30 , the grinding wheel cover 40 , and the push rod type stop mechanism includes a push rod 50 , a stop pin 60 and a spring 70 .

[0021] The push rod 50 is located below the reduction box cover 12, one end of which is a shaft end 51 that is rotatably connected to the angle grinder body 10 along a vertical plane, and the other end is used to pull the The free end 52 of the push rod 50 rotates.

[0022] The lower end of the stop pin 60 is fixedly connected to the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com