Tight focus spot energy optimization method and device for femtosecond laser three-dimensional micromachining

A femtosecond laser, energy optimization technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as lack of accuracy, and achieve the effects of simple installation, adjustable laser space energy distribution, and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

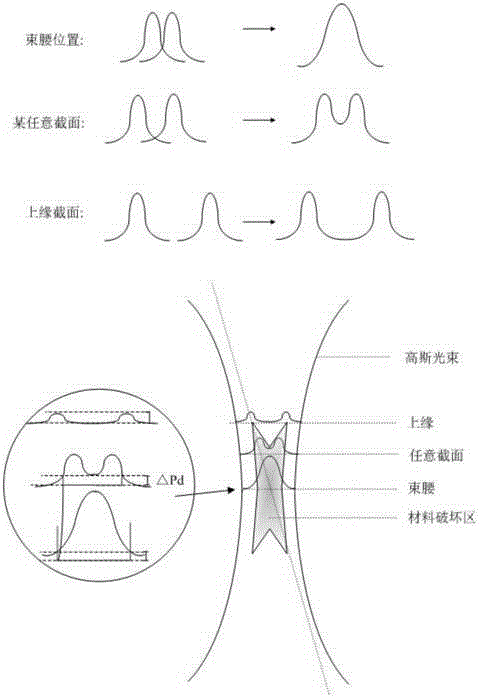

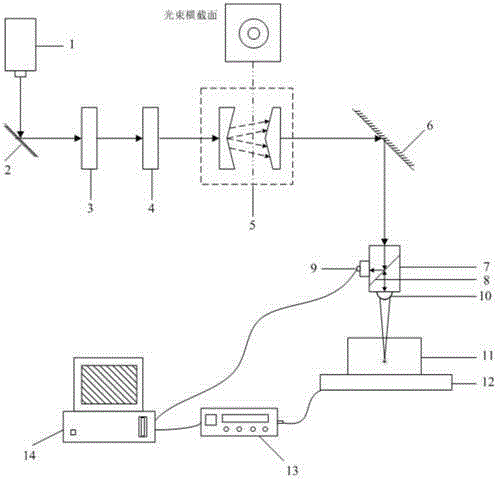

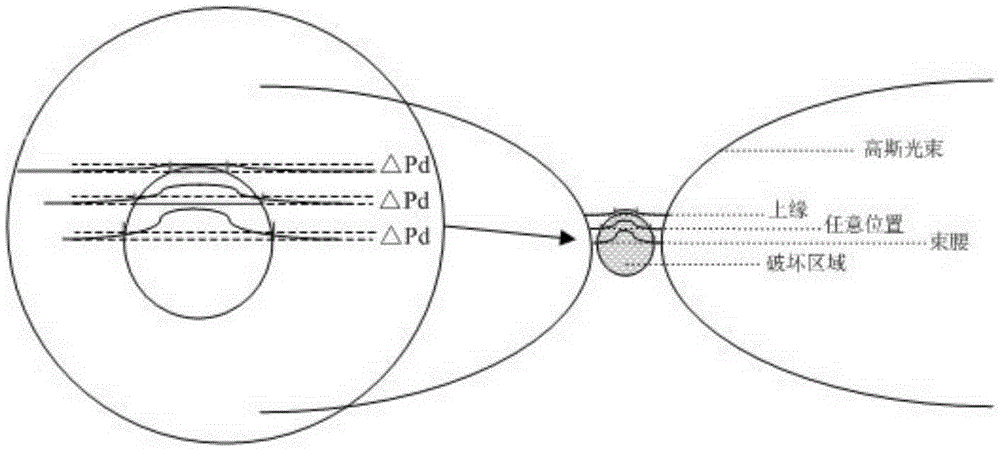

[0029] The tightly focused spot energy optimization method for femtosecond laser three-dimensional micromachining of the present invention comprises:

[0030] Step 1, the femtosecond laser generates a femtosecond laser beam, and the femtosecond laser beam is reflected by the first reflector to the surface of the attenuation sheet to attenuate the laser energy;

[0031] Step 2: Control the diameter of the spot through the aperture, measure the average power of the femtosecond laser beam with a laser power meter, and adjust the average power by rotating the attenuation sheet; finally modulate the femtosecond laser beam through the beam energy conversion system Laser beam to obtain the required central energy attenuation spot;

[0032] Step 3, the central attenuated light obtained in step 2 is introduced into the microfocus system through the second mirror, and after passing through the microfocus system, a focused spot is generated inside the sample;

[0033] Step 4, write the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com