Production process for preparing astragalus polysaccharide lipidosome nano preparation

A technology of astragalus polysaccharide and production process is applied in the field of production technology for preparing astragalus polysaccharide liposome nano-preparation, and can solve the problems of difficulty in meeting market demands, low drug efficacy, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

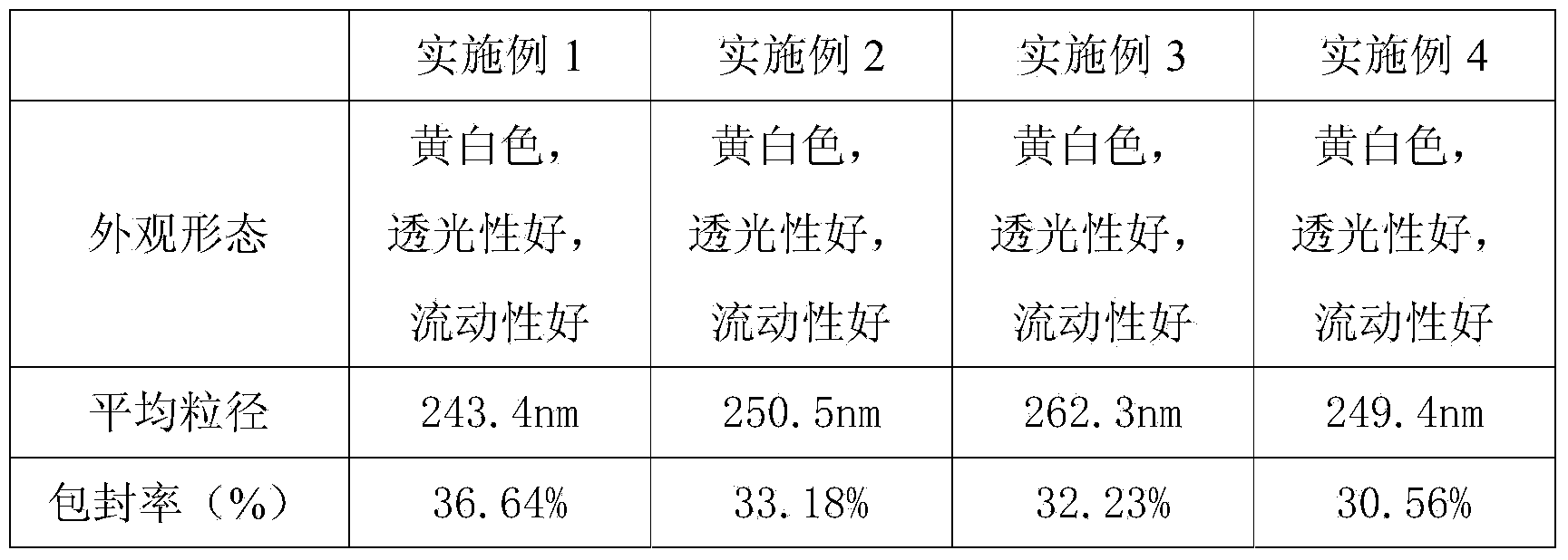

Examples

Embodiment 1

[0014] Accurately weigh analytically pure soybean lecithin (300mg) and cholesterol (75mg) according to the mass ratio of 4:1, and dissolve them in absolute ethanol (4ml) to make a lipid solution with a mass concentration of 7.5%;

[0015] Dissolve astragalus polysaccharide (100mg) with pH 7.0 phosphate buffer (25ml) and stir (55°C constant temperature, 1800r / min) to make astragalus polysaccharide solution with a mass concentration of 0.4%;

[0016] While stirring the astragalus polysaccharide solution obtained in step , slowly inject the lipid solution obtained in step at a volume ratio of 3:1, using a No. 5 syringe needle and keeping the needle below the liquid level, continue Stir for 1 hour, remove ethanol by volatilization to obtain astragalus polysaccharide liposome suspension;

[0017] Pass the astragalus polysaccharide liposome suspension obtained in step sequentially through 0.45 μm and 0.22 μm filter membranes to obtain a transparent milky liquid, which is store...

Embodiment 2

[0019] Accurately weigh analytically pure soybean lecithin (300mg) and cholesterol (150mg) according to the mass ratio of 2:1, and dissolve them in absolute ethanol (4ml) to make a lipid solution with a mass concentration of 15%;

[0020] Dissolve astragalus polysaccharide (100mg) with pH 7.5 phosphate buffer (25ml) and stir (65°C constant temperature, 1500r / min) to make astragalus polysaccharide solution with a mass concentration of 1.0%;

[0021] While stirring the astragalus polysaccharide solution obtained in step , slowly inject the lipid solution obtained in step at a volume ratio of 4:1, using a No. 5 syringe needle and keeping the needle below the liquid level, continue Stir for 1 hour, remove ethanol by volatilization to obtain astragalus polysaccharide liposome suspension;

[0022] Pass the astragalus polysaccharide liposome suspension obtained in step sequentially through 0.45 μm and 0.22 μm filter membranes to obtain a transparent milky liquid, which is store...

Embodiment 3

[0024] Accurately weigh analytically pure soybean lecithin (300mg) and cholesterol (50mg) according to the mass ratio of 6:1, and dissolve them in absolute ethanol (4ml) to make a lipid solution with a mass concentration of 10%;

[0025] Dissolve astragalus polysaccharide (100mg) with pH 7.5 phosphate buffer (25ml) and stir (45°C constant temperature, 1600r / min) to make astragalus polysaccharide solution with a mass concentration of 0.3%;

[0026] While stirring the astragalus polysaccharide solution obtained in step , slowly inject the lipid solution obtained in step at a volume ratio of 5:1, using a No. 5 syringe needle and keeping the needle below the liquid level, continue Stir for 1 hour, remove ethanol by volatilization to obtain astragalus polysaccharide liposome suspension;

[0027] Pass the astragalus polysaccharide liposome suspension obtained in step sequentially through 0.45 μm and 0.22 μm filter membranes to obtain a transparent milky liquid, which is stored...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com