Watch chain link pin and manufacturing method thereof as well as watch chain link connecting structure

A connection structure and technology for watches, applied in the field of watches, can solve the problems of increasing the risk of bracelets, inconvenient assembly and disassembly, and short service life, and achieve the effects of reducing the risk of unraveling, simplifying the assembly and disassembly process, and having a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

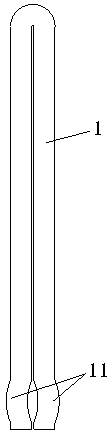

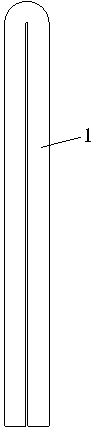

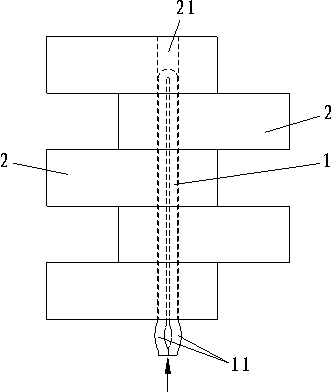

[0022] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~4 As shown, the watch chain link plug of the present invention includes a plug 1 made of a shape memory alloy, and a convex portion 11 is formed on the side of the plug 1 to protrude outward. The plug 1 is a shape memory alloy with two-way memory effect, the phase transition temperature is 30-50°C, the high-temperature phase shape is a linear structure without protrusions 11, and the low-temperature phase shape is a long strip structure with protrusions 11. 1 Deform to a linear structure at a temperature of 30~50°C.

[0023] Pin 1 is Ni-Ti alloy, and Ni-Ti alloy can be added with Nb, Cu, Mo, V and other metals. Of course, pin 1 can also be Au-Cd, Ag-Cd, Cu-Zn, Cu-Zn-Al, Cu -Zn-Sn, Cu-Zn-Si, Cu-Sn, Cu-Zn-Ga, In-Ti, Au-Cu-Zn, NiAl, Fe-Pt, Ti-Ni-Pd, Ti-Nb, U-Nb Or alloys such as Fe-Mn-Si.

[0024] The latch 1 is made of a shape memory alloy metal strip folded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com