Damping closing structure of buried-type hinge

A closed structure and embedded technology, which is applied in building structures, switches with braking devices, door/window accessories, etc., can solve the problem of not having a good buffer effect, affecting the life of the buffer, and the impact force of furniture. and other problems, to achieve the effect of quick opening and/or closing operation, prolonging the service life and prolonging the working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

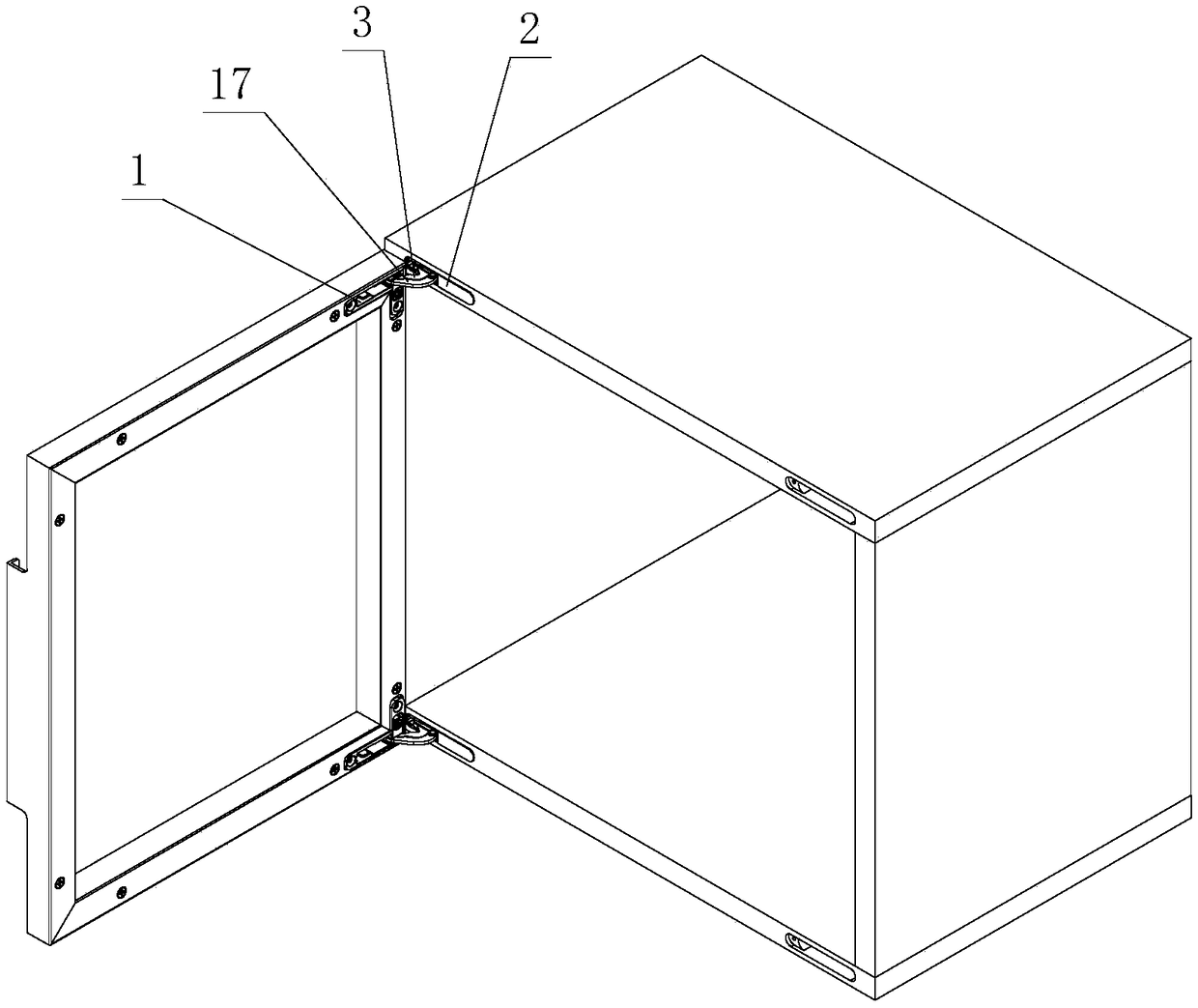

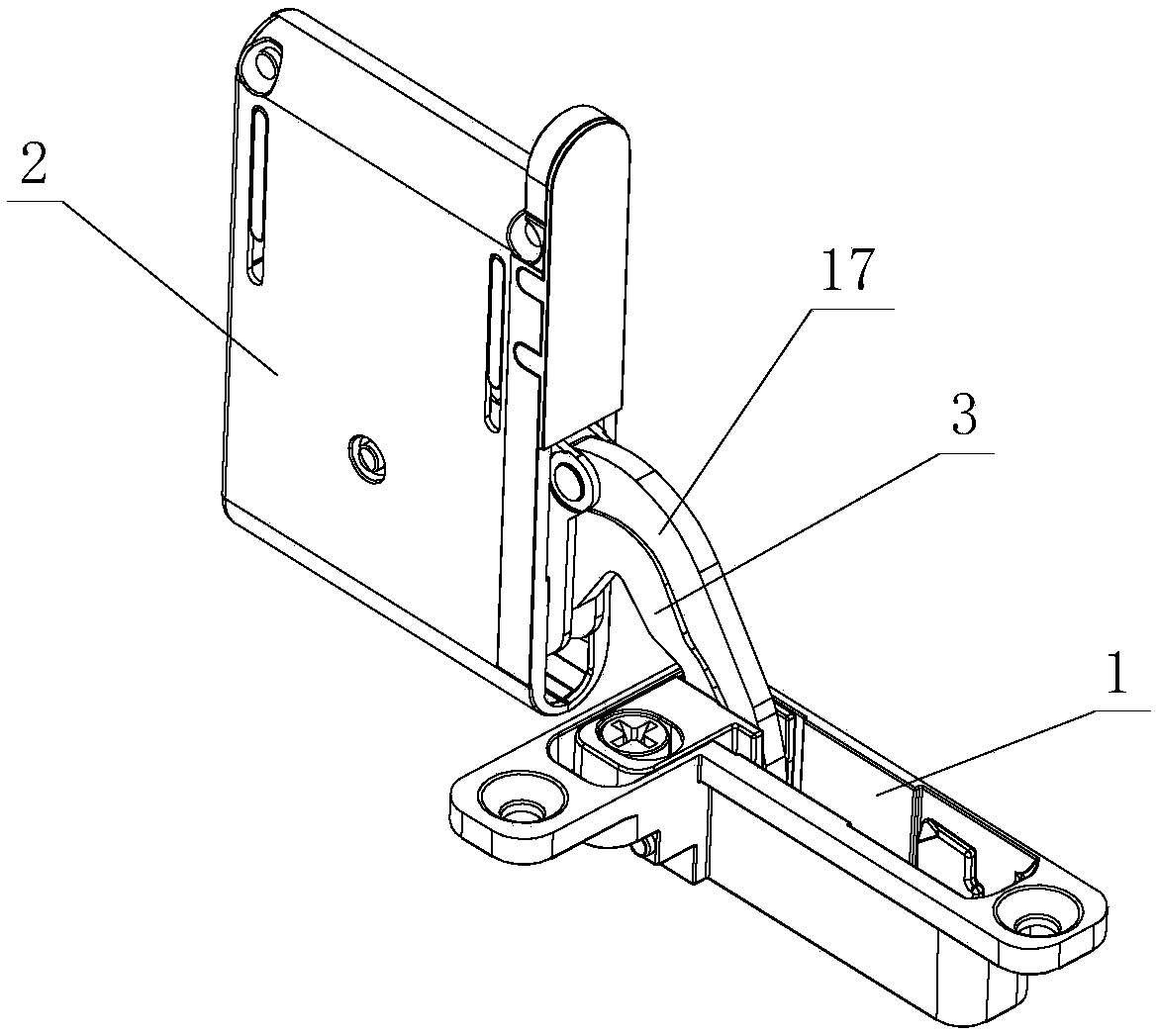

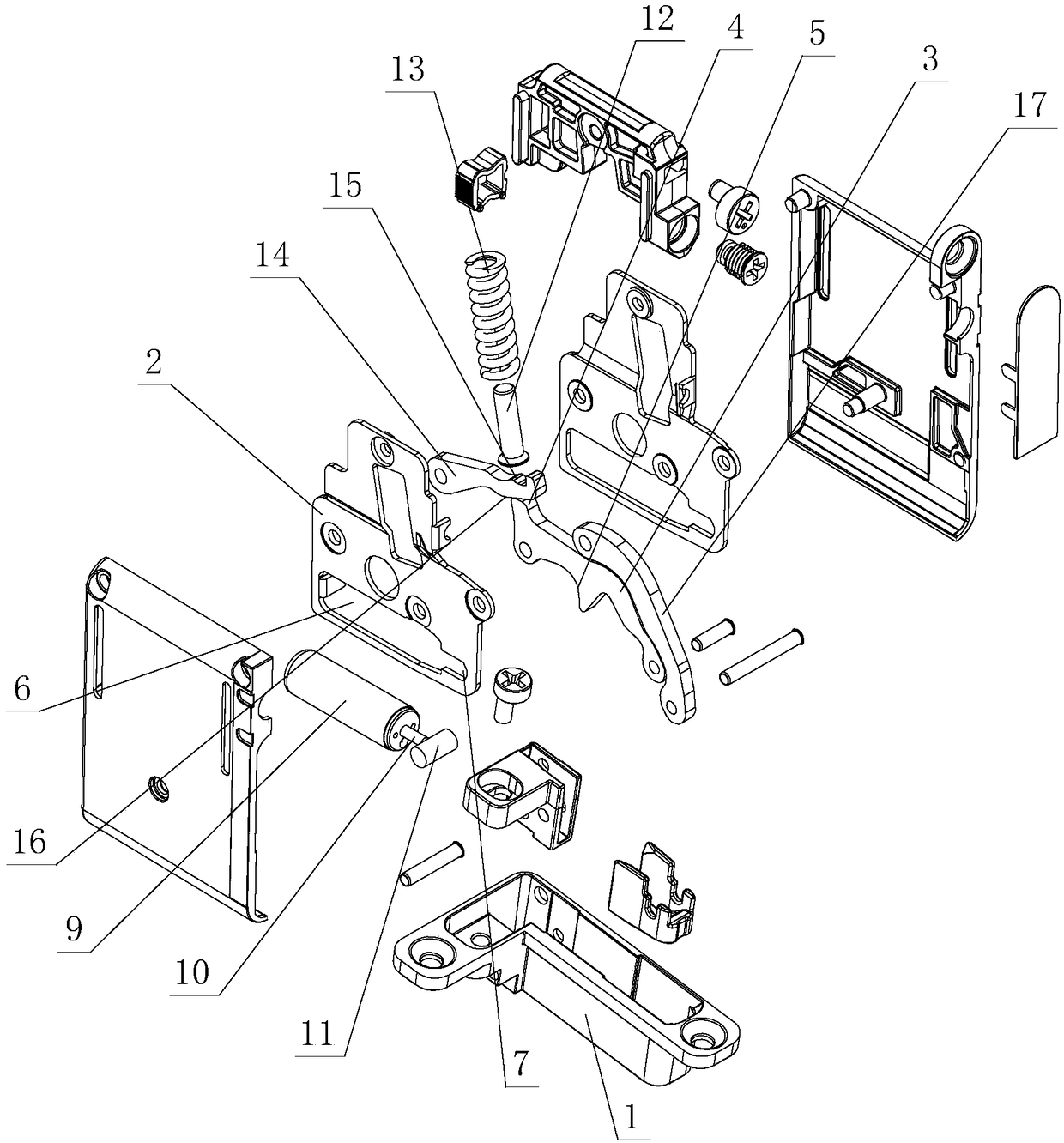

[0026] see Figure 1-Figure 7 , the damping closure structure of the embedded hinge includes the hinge cup 1 and the fixed bracket 2 that are hinged to each other through the connecting arm assembly. The connecting arm assembly includes at least the first connecting arm 3, and the two ends of the first connecting arm 3 are respectively connected Bracket 2 and hinge cup 1 are rotatably connected, elastic components and dampers are also arranged on fixed bracket 2, elastic action part 4 and damping action part 5 are also arranged on first connecting arm 3; described first connecting arm 3 is in When the hinge cup 1 is hinged and opened and closed relative to the fixed bracket 2 at a certain position, the elastic action part 4 interacts with the elastic component to realize the elastic hinge opening and closing of the hinge cup 1 relative to the fixed brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com