Final cutting drum for passim coiler

A final cutting and drum technology, applied in application, tobacco, food science and other directions, can solve the problems of excessive cigarette length, reduced cigarette cutting quality, skewed mouth incision, etc., to reduce maintenance costs, improve cutting quality, avoid The effect of disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

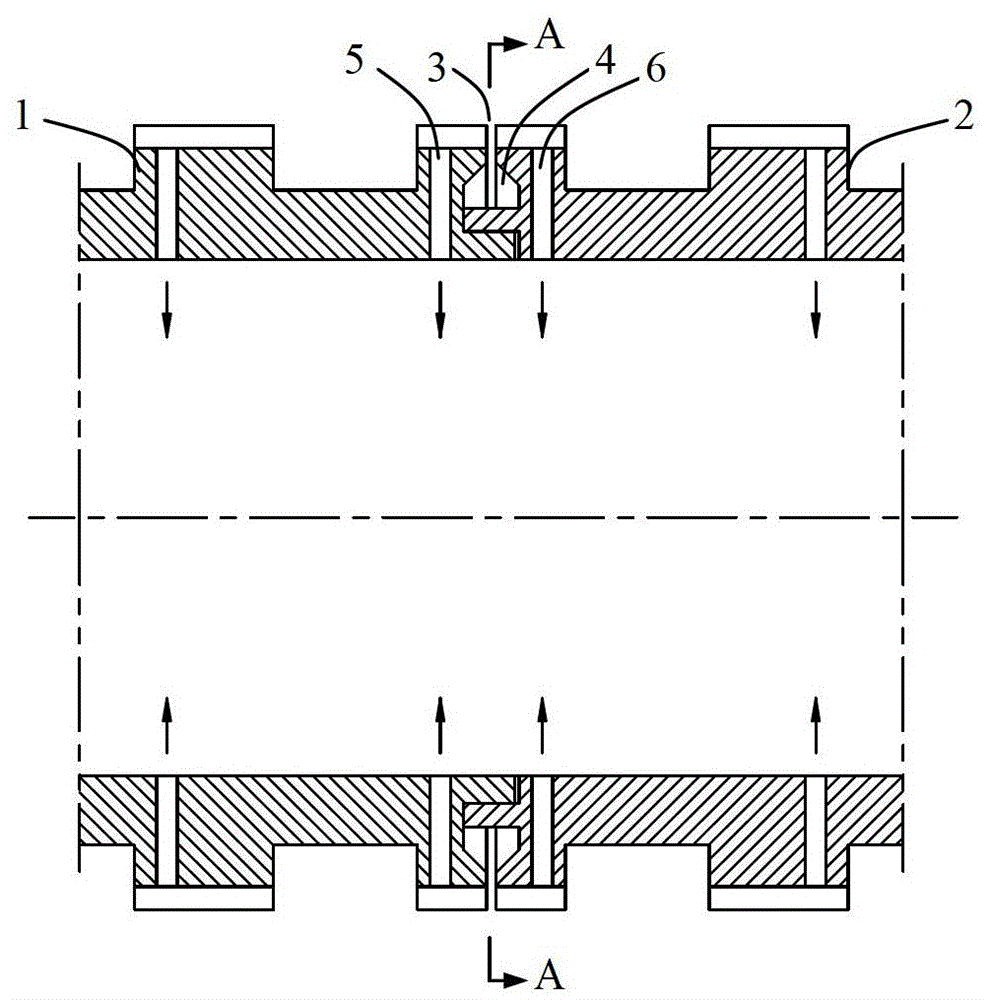

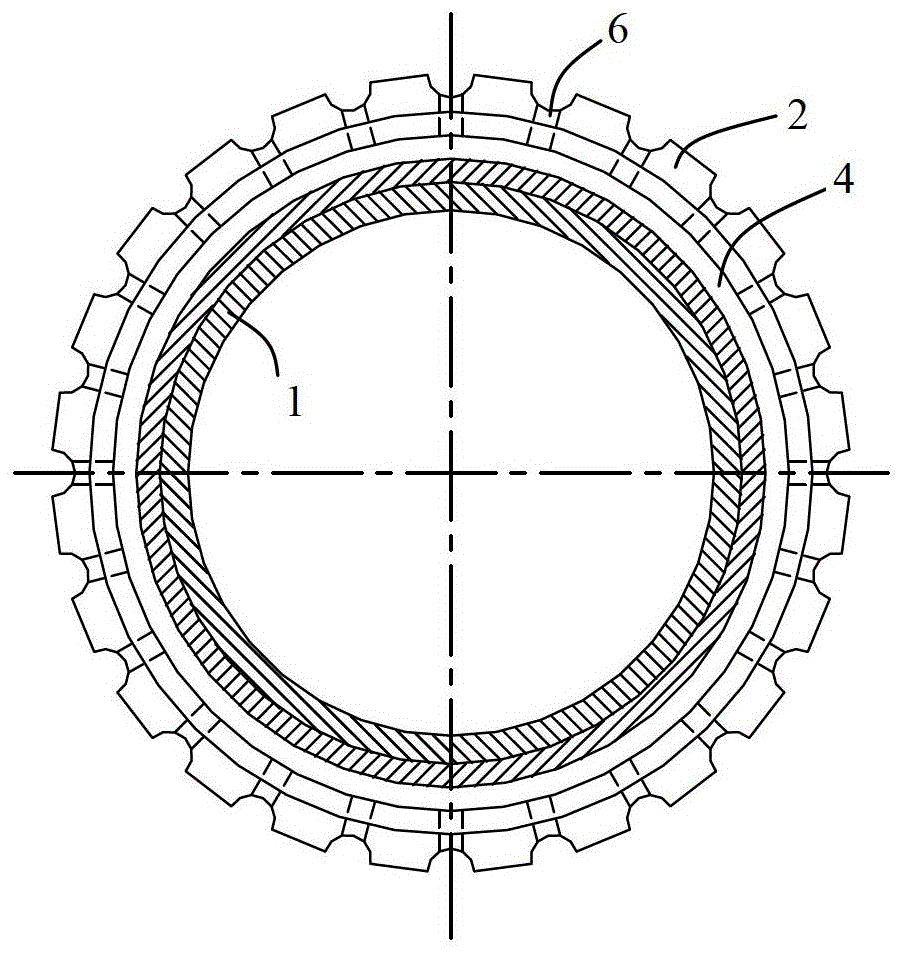

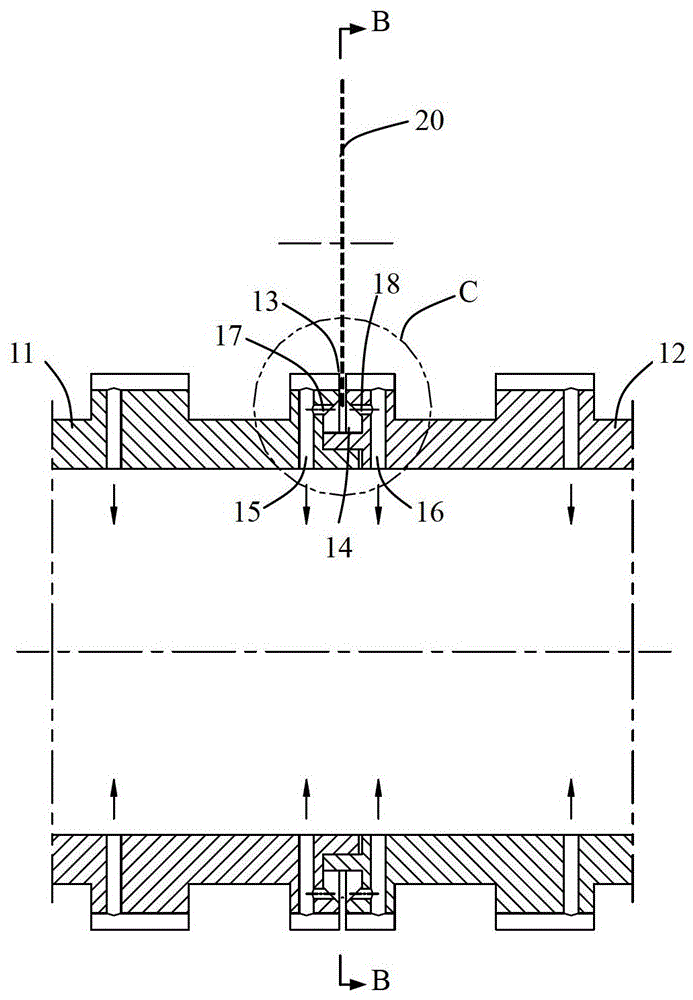

[0015] See Figure 3~5 , The final cutting drum used for the PASSIM crimping unit of the present invention includes a left drum 11 and a right drum 12, the left drum 11 and the right drum 12 are fixedly connected and a circumferential knife groove is formed at the joint 13 and a circumferential chip groove 14, the knife groove 13 and the chip groove 14 are connected, the left drum 11 and the right drum 12 are respectively provided with a plurality of left drum groove suction holes 15 and Right drum groove suction hole 16. The final cutting drum for the PASSIM crimping unit of the present invention also includes a plurality of left drain holes 17 connecting the chip pocket 14 with the plurality of left drum groove suction holes 15, and a plurality of cleaning holes. The chip pocket 14 is connected to the right drain hole 18 of the plurality of right drum groove suction holes 16. Use the left drum groove suction hole 15 and the right drum groove suction hole 16 to timely pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com