Axial turbine

An axial-flow turbine, turbine technology, applied in the direction of impact engine, reaction engine, non-variable-capacity engine, etc., can solve the efficiency of the damage distance of the wing plate, the site conditions that cannot be selected, and the angle of the turbine wing plate. Efficiency maximization and other issues, to achieve the effect of large distance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

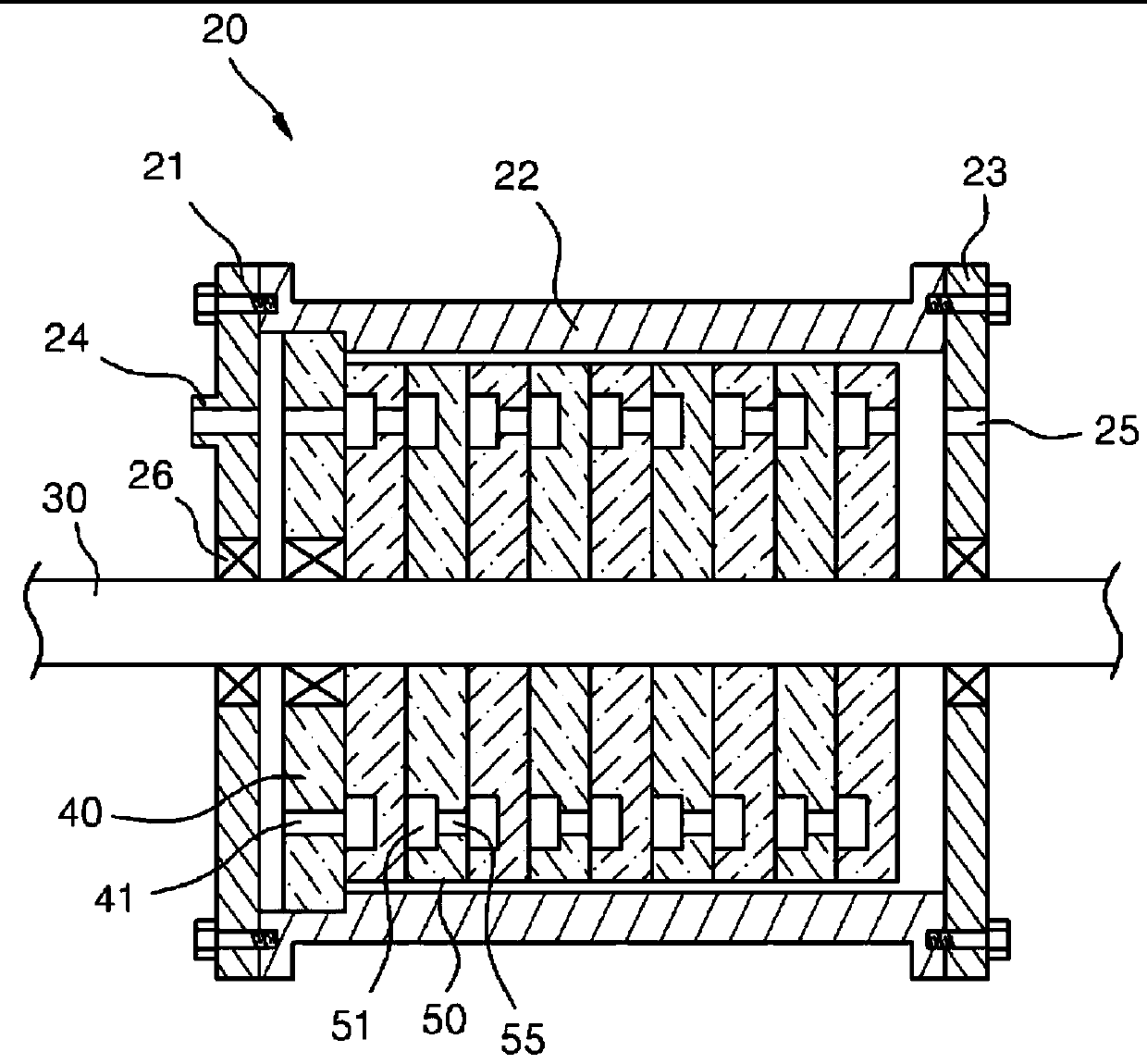

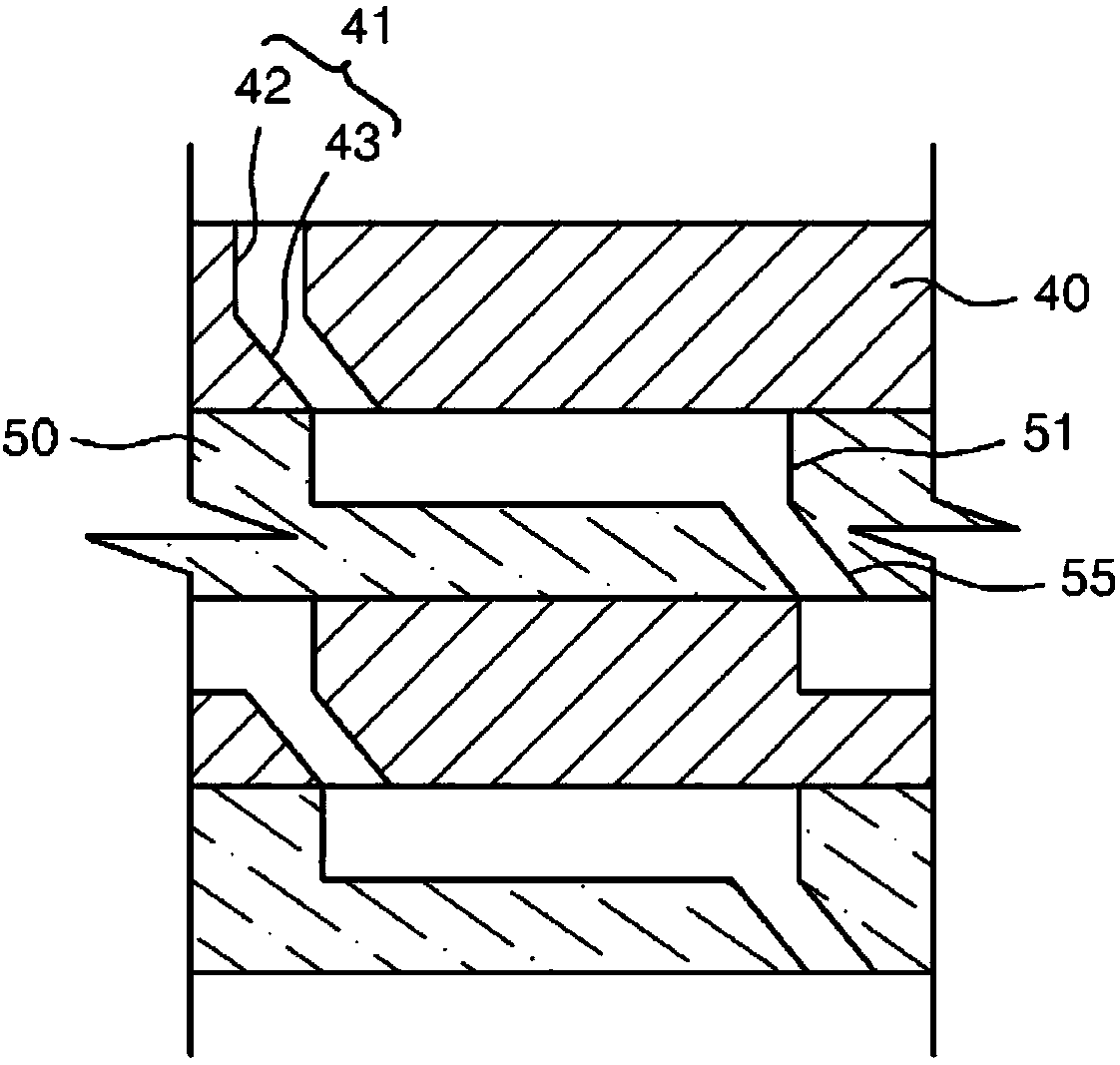

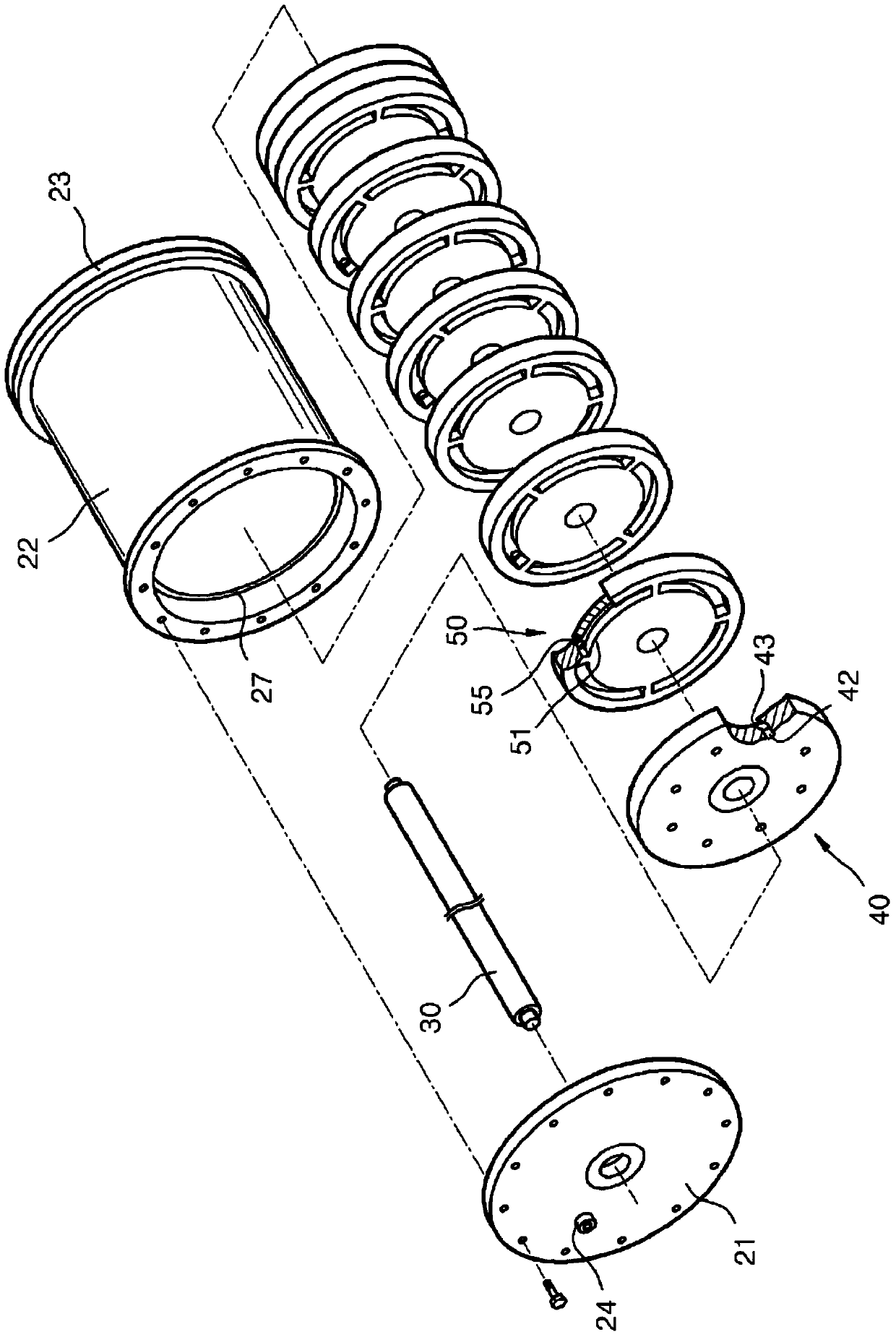

[0064] The improved structure applied to the axial flow turbine of the present invention is as Figure 2 to Figure 23 shown.

[0065] In describing the present invention, when a detailed description of related known functions and structures would unnecessarily obscure the essence of the present invention, the detailed description will be omitted.

[0066] In addition, the following terms are set in consideration of their functions in the present invention and may be different from the manufacturer's intention and custom, and their definitions should be based on the contents of the entire specification.

[0067] First, the invention relates to axial flow turbines and includes a fluid filled submerged turbine 100 . The turbine includes: a main body 110 having a space 111, an inlet 112 and an outlet 113, the interior of the space 111 is filled with fluid, and the inlet 112 and the outlet 113 are respectively located on one side and the opposite side of the main body; a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com