Motor rotor assembly

A technology of motor rotors and components, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of large amount of magnetic ring materials, poor magnetic ring induction, complex structure, etc., and achieve good induction effect, The induction magnetic field is uniform and the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

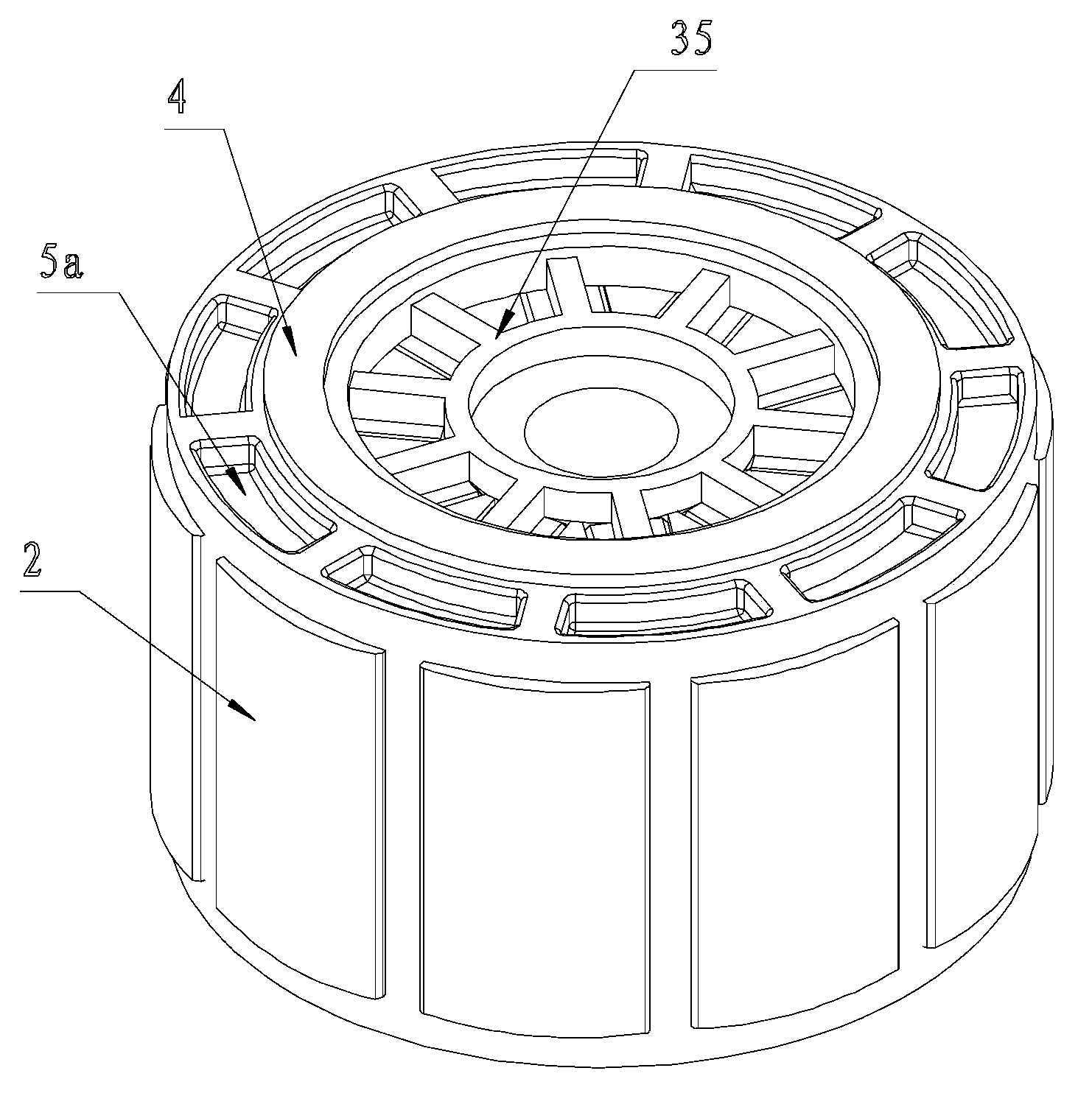

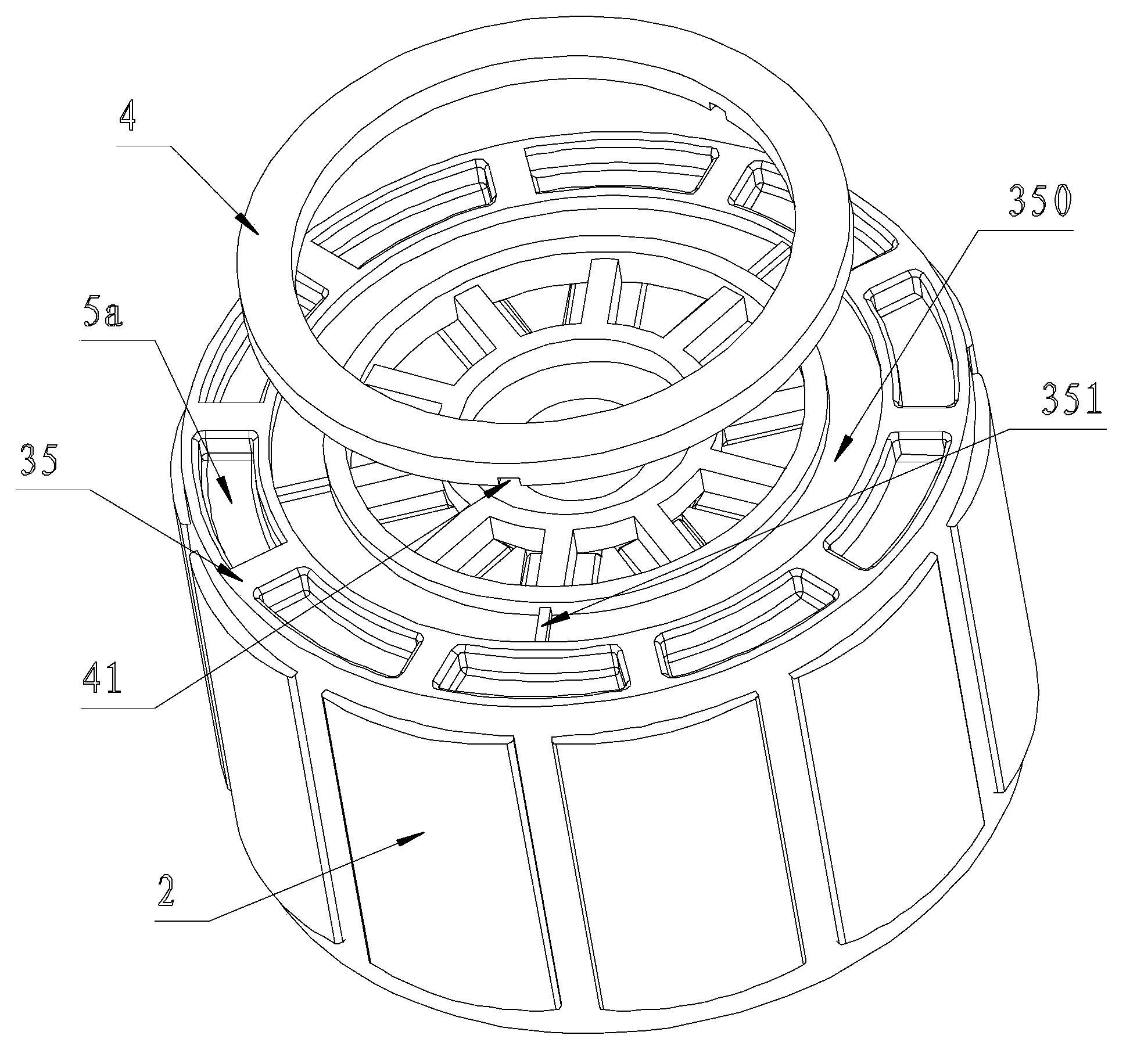

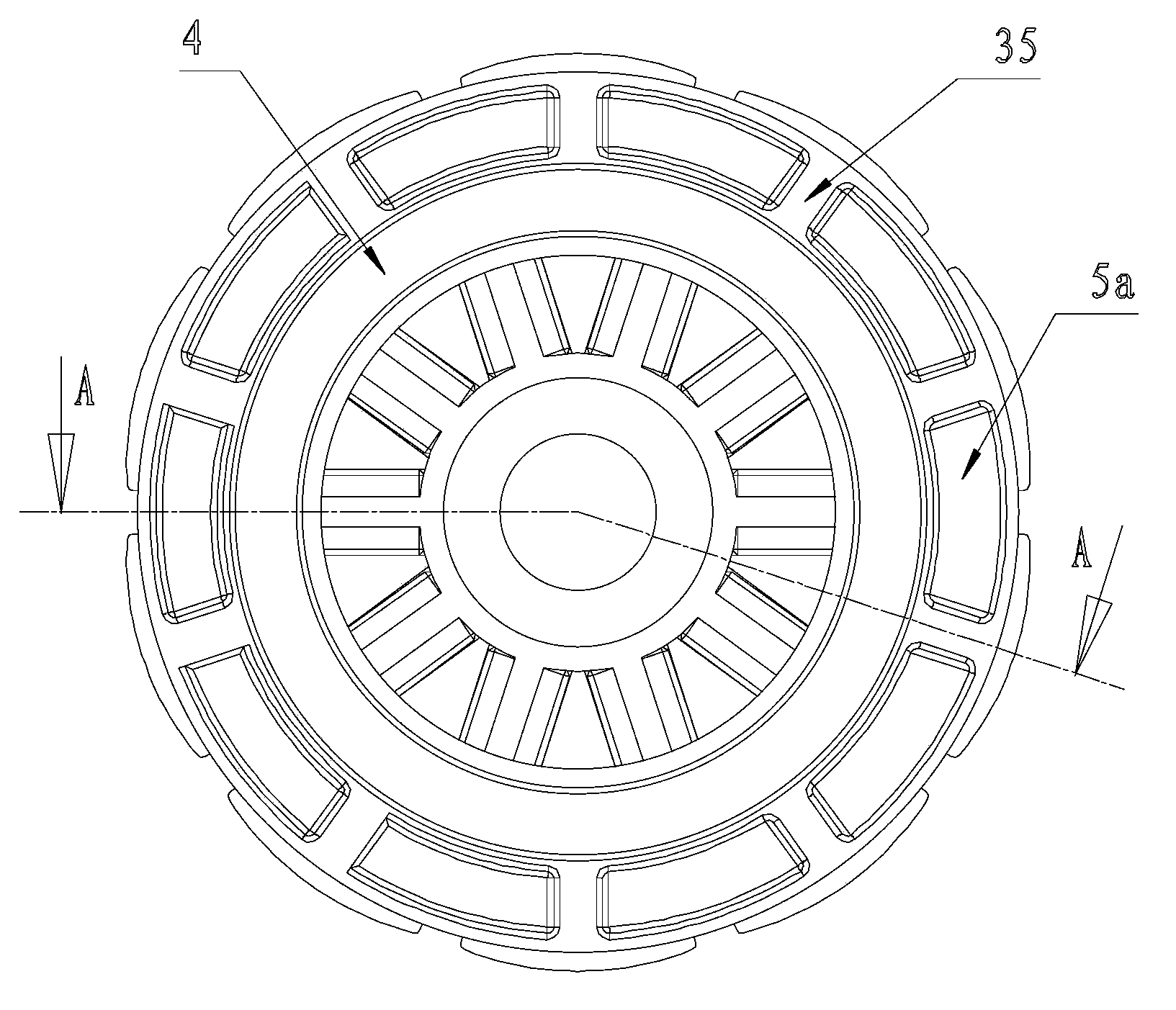

[0030] Embodiment one: if figure 1 and Figure 8 As shown, the present invention is a motor rotor assembly, including a permanent magnet 1, a rotor core 2 and a magnetic ring 4, and the rotor core 2 includes an annular ring 22 provided with a central axis hole 21 and protruding from the outer side of the annular ring 22 A plurality of magnetic conductive blocks 23, through holes 27 are opened on the magnetic conductive blocks 23, radial grooves 24 are formed between two adjacent magnetic conductive blocks 23, the permanent magnets 1 are embedded in the radial grooves 24, and the rotor core 2 An end plate 35 and a bottom plate 36 are respectively injection-molded on the end face and the bottom face of the end plate 35 and the bottom plate 36 are connected into a whole through the connecting column 37 passing through the through hole 27, and an annular groove 350 is arranged on the end face of the end plate 35, and the magnetic ring 4 Embedded in the groove 350 li.

Embodiment 2

[0031] Embodiment two: if figure 2 As shown, on the basis of Embodiment 1, the following technical features are added: a number of clamping blocks 351 protrude from the bottom of the groove 350 and the end plate 35 , and the clamping blocks 351 are embedded in the clamping groove 41 opened on the bottom surface of the magnetic ring 4 .

Embodiment 3

[0032] Embodiment three: as Figure 4 As shown, the following technical features are added on the basis of Embodiment 1 or Embodiment 2: the magnetic ring 4 is concentric with the central shaft hole 21 , and the magnetic ring 4 is adsorbed by the rotor core 2 and tightly attached to the end plate 35 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com