Forming method of electronic-type switch applied to direct-current brushless motor

A DC brushless motor and electronic technology, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of softness, short life of electric switches, small finger movement range, etc., and achieve compact structure, low cost and wide range of motion small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Below in conjunction with the preferred embodiment shown in the accompanying drawings, the present invention will be further described in detail:

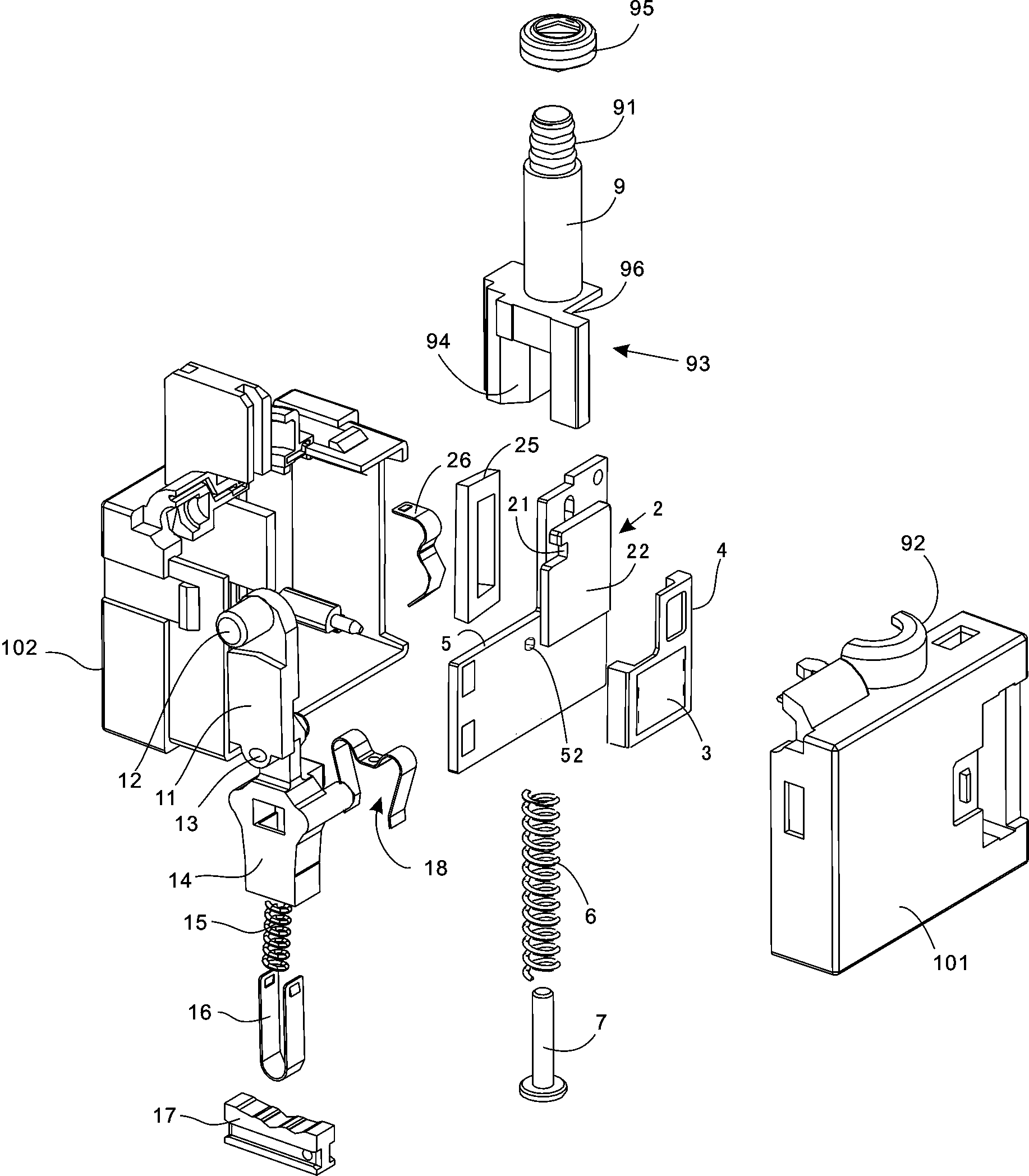

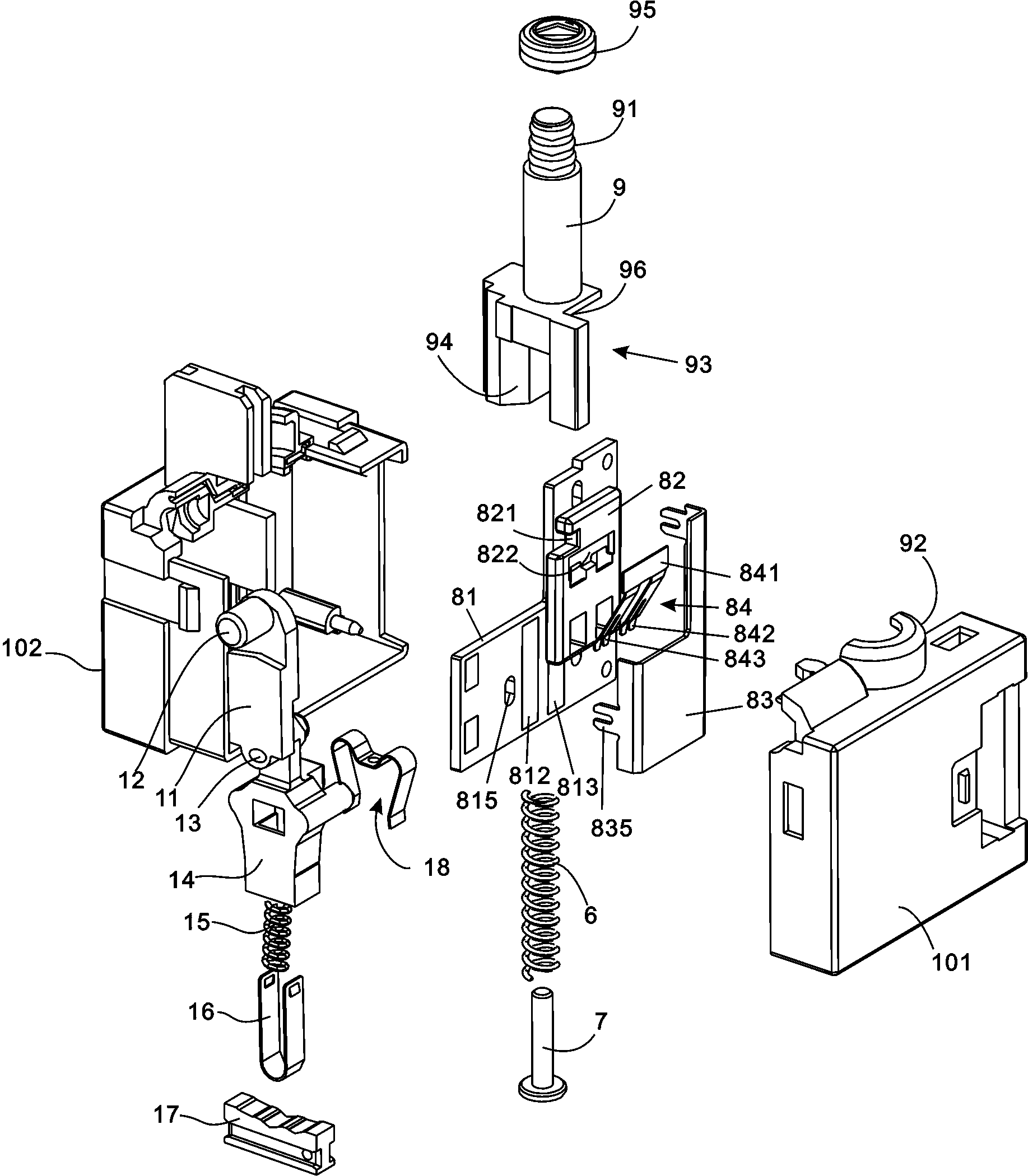

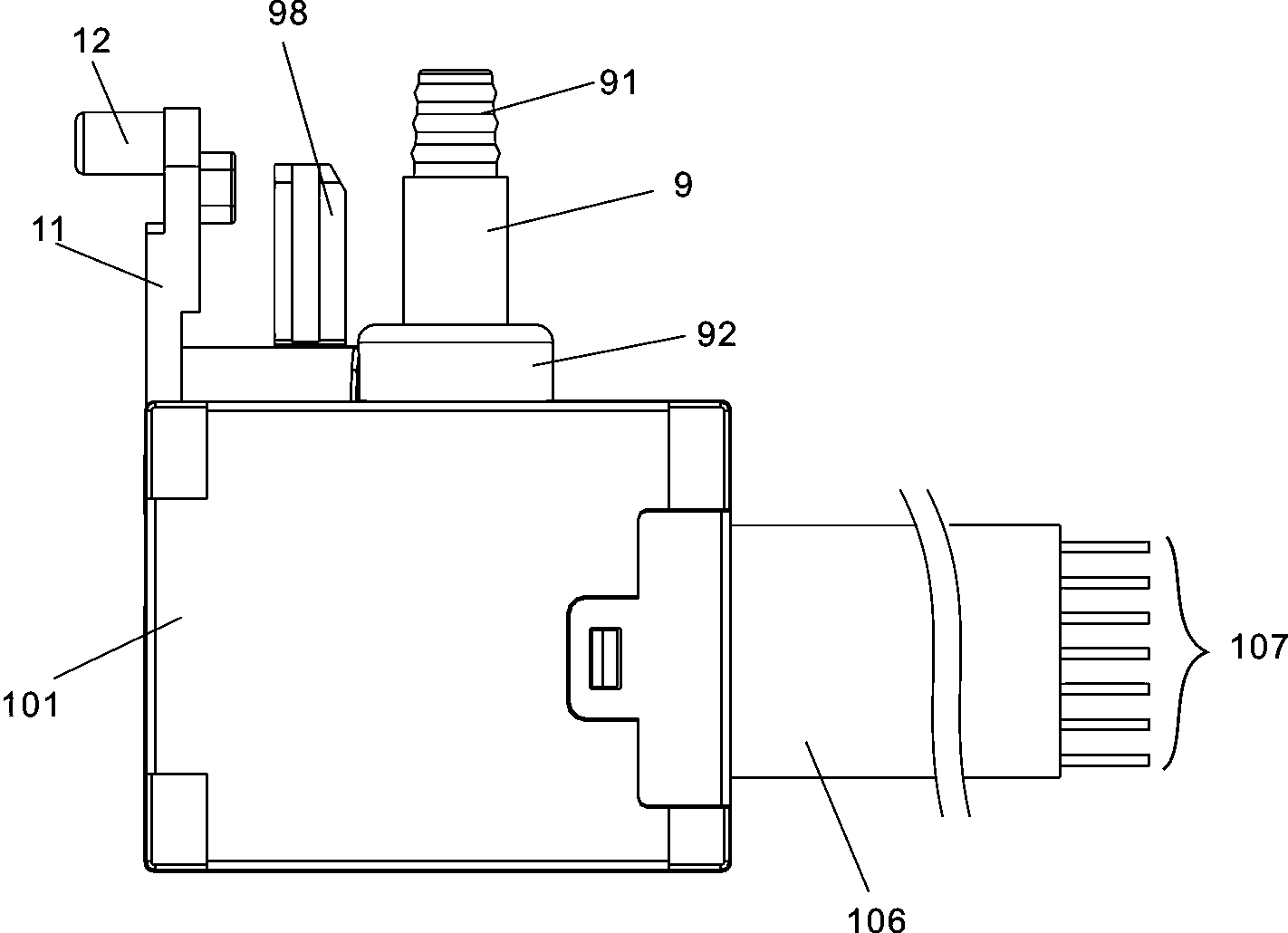

[0089] Implementation of an electronic switch applied to a DC brushless motor constitutes a method such as Picture 1-1 , Figure 2 to Figure 8 shown.

[0090] Method of the present invention comprises steps:

[0091] A. First, a housing is provided, and the housing is composed of a right housing 101 and a left housing 102; then the right housing 101 and the left housing 102 are provided to clamp a button main shaft 9 to slide up and down on the housing;

[0092] B. Next, the button spindle 9 is set to connect the spindle clamping part 93 inside the housing. The spindle clamping part 93 has a spindle clamping groove 96 and a spindle compression spring hole 94; the spindle compression spring hole 94 is provided to accommodate the spindle compression spring 6; Set the main shaft compression spring 6 to be set on the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com