Top shaft multistage rapid flushing gate

A fast flushing and shaft jacking technology, applied in water conservancy projects, artificial waterways, marine engineering and other directions, can solve problems such as the inability to control the drainage of irrigation canals, and achieve the effects of low pressure, simple structure, and reduced size and strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

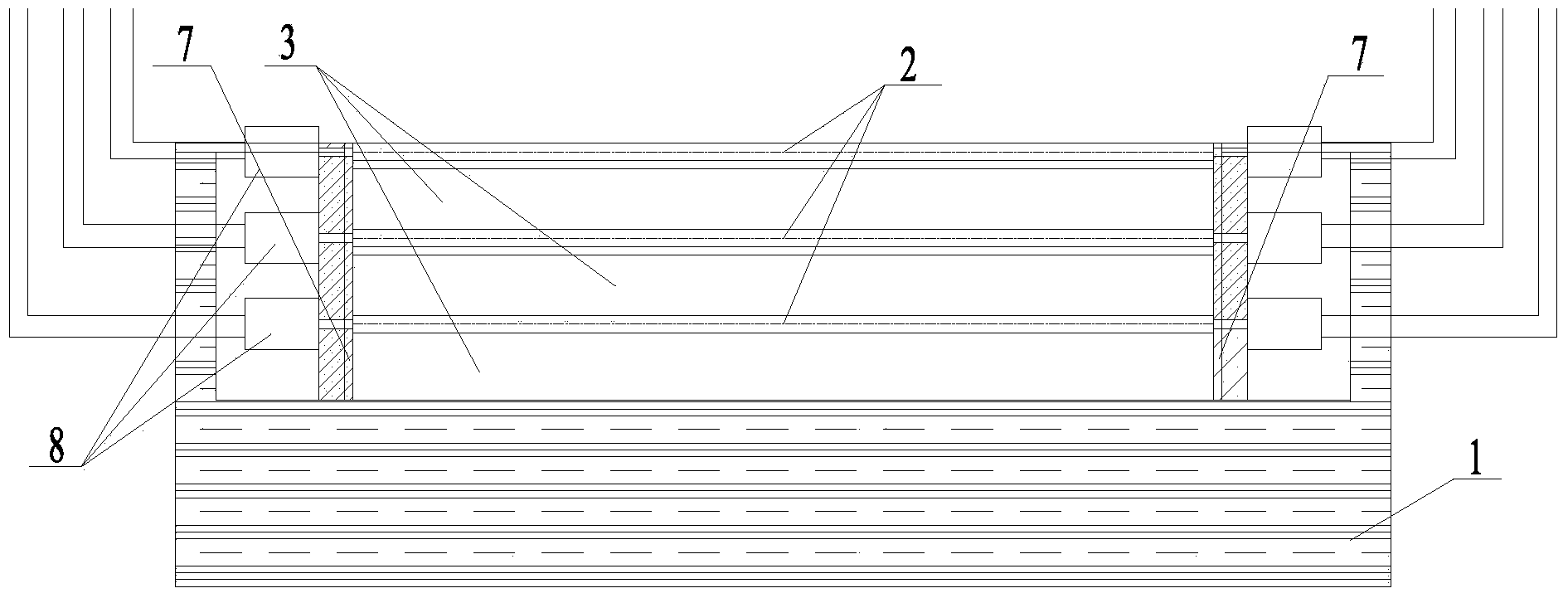

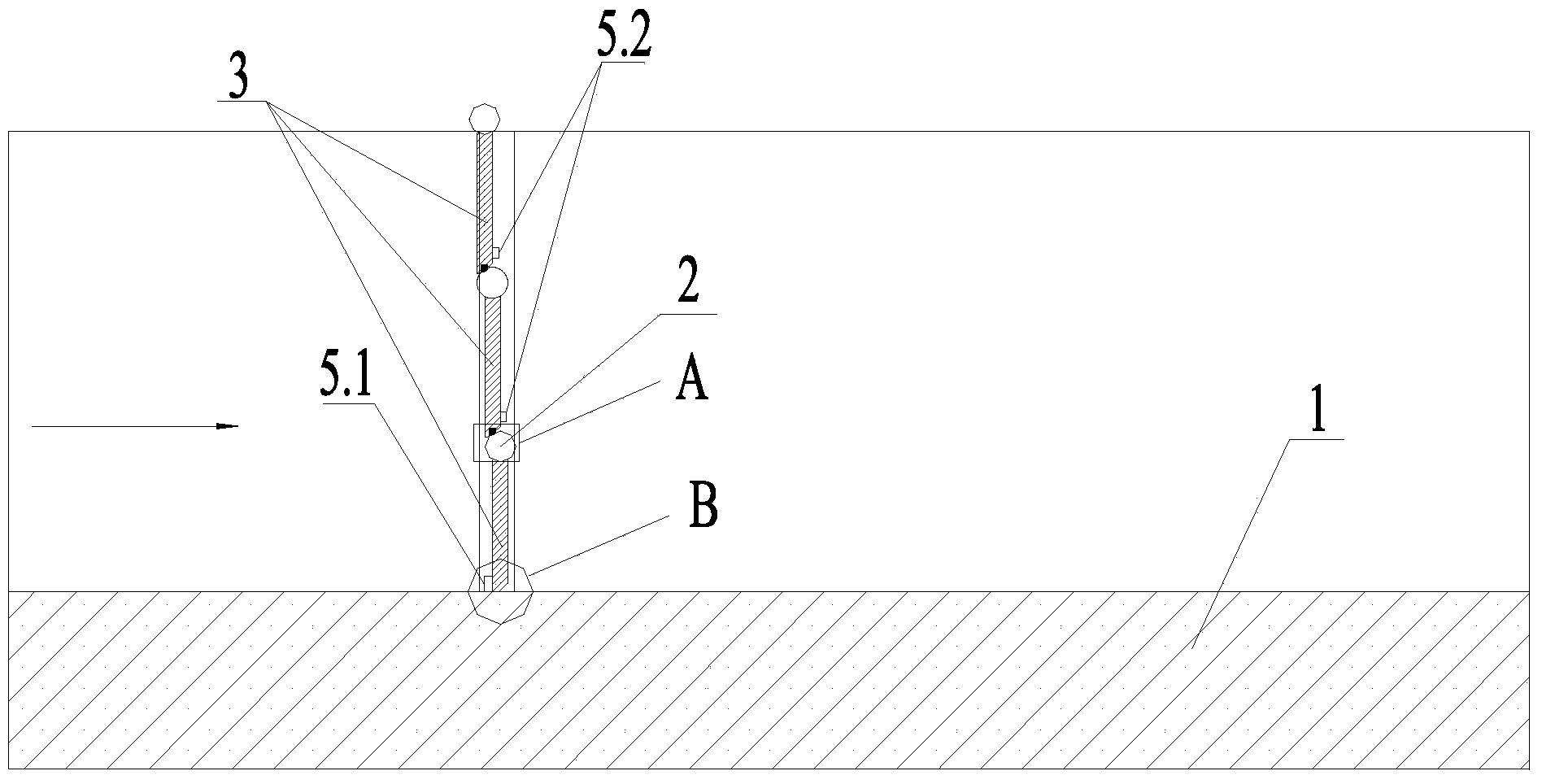

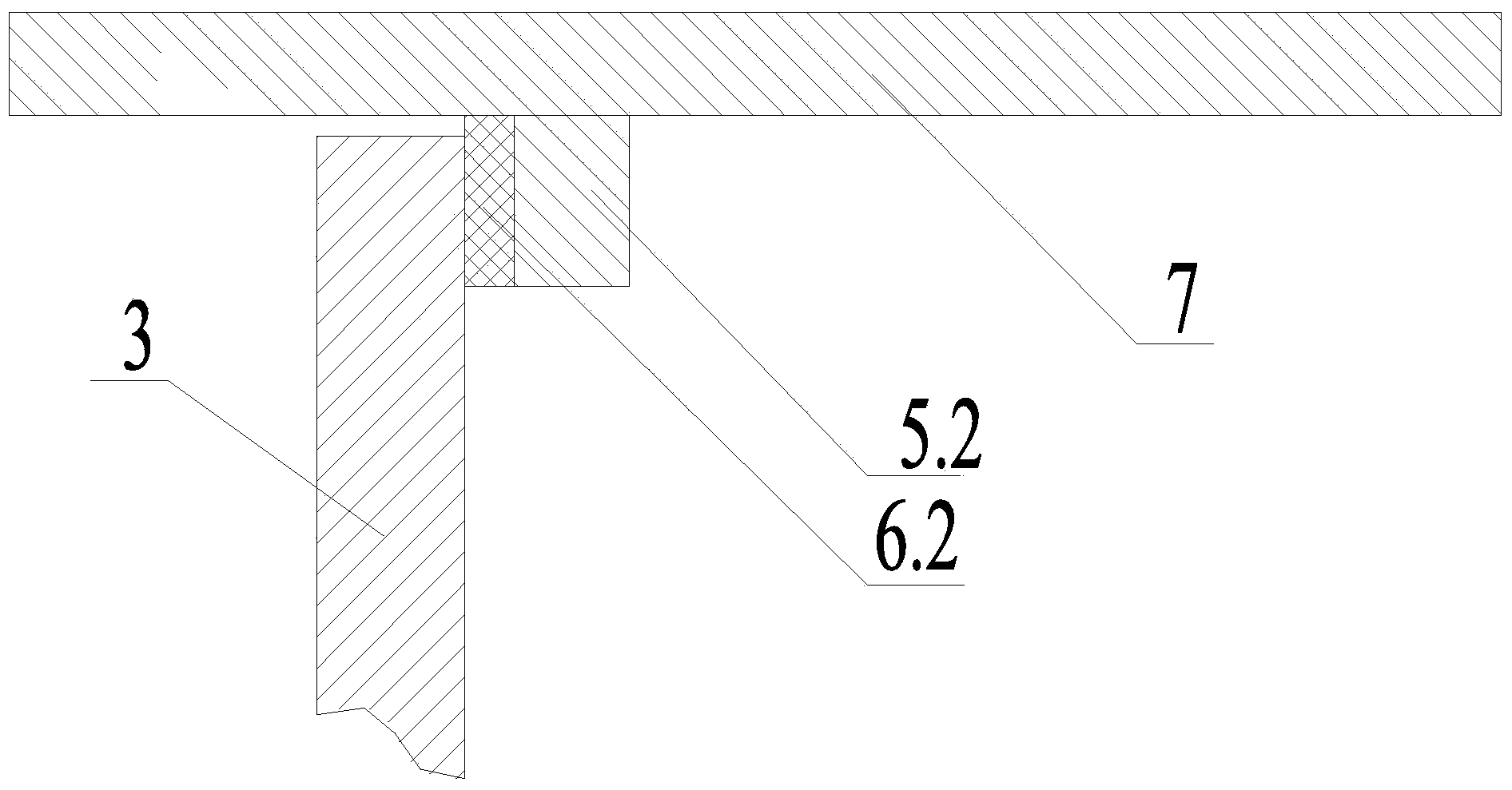

[0022] Such as figure 1 - The jacking shaft multi-stage fast flushing door shown in 2 includes a pipe foundation 1, a rotating shaft 2 is connected between the pipe foundation 1 on opposite sides, and the rotating shaft 2 is connected with a weir plate 3, and the weir plate 3 is vertically There are at least two pieces in the direction, and the top of each weir plate 3 is provided with a rotating shaft 2, such as figure 2 and Figure 4 As shown, a weir plate gasket 4 that can be compressed and sealed with the rotating shaft 2 is provided between the rotating shaft 2 and the weir plate 3 above it, and the weir plate sealing gasket 4 is fixed on the bottom of the weir plate 3, as shown in figure 2 and Figure 5 As shown, the bottom pipe foundation 1 is fixed with a first limit stopper 5.1, and the first limit stopper 5.1 is fixed with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com