Vertical skid-resistant friction plate used for improving skid-resistant safety of welding-type cable saddle

A friction plate and welded technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of economical reduction and achieve the effects of good deformation coordination, large longitudinal shear force, and small vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

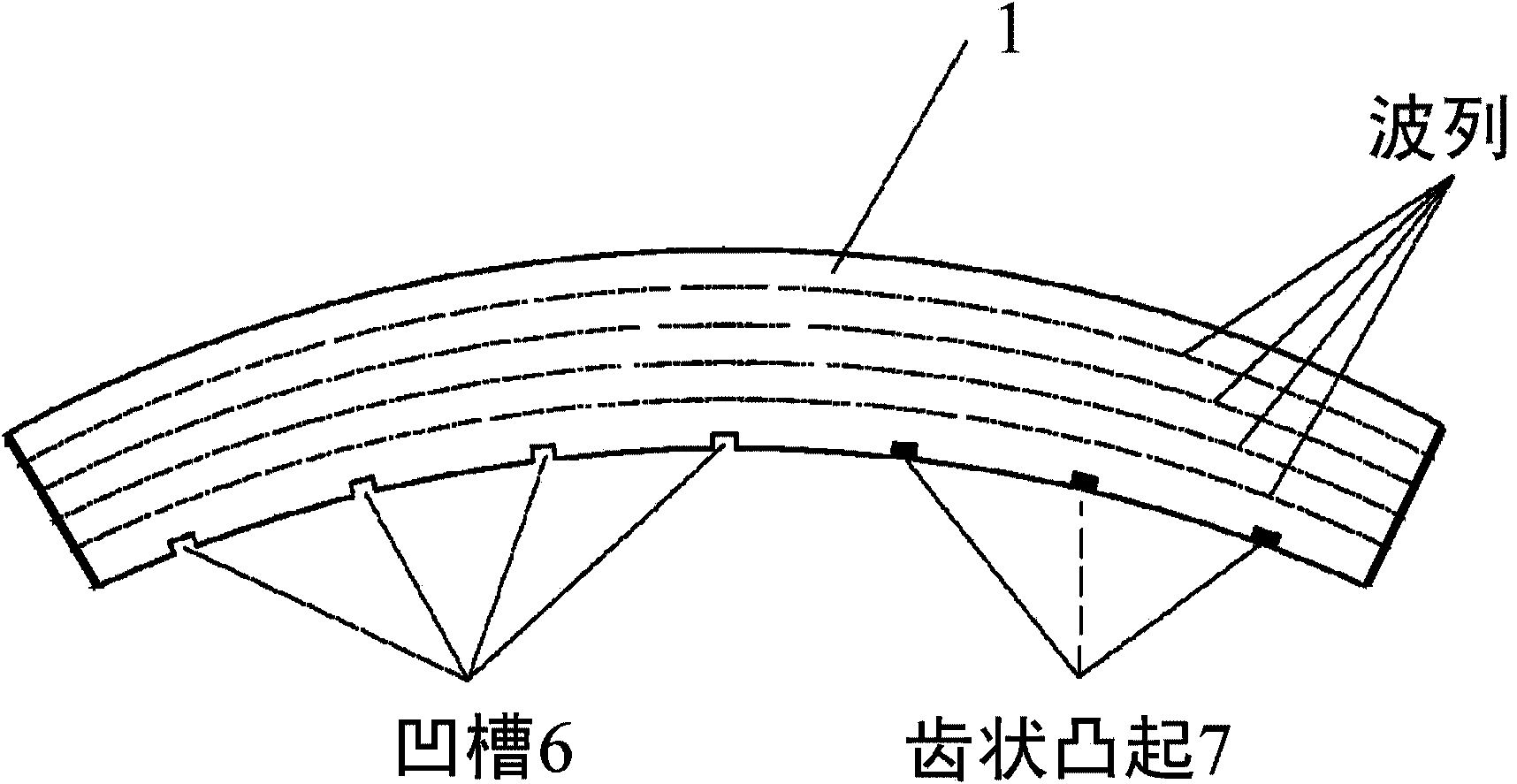

[0027] Such as figure 1 As shown, the vertical anti-slip friction plate 1 provided by the present invention for improving the anti-skid safety of the welded cable saddle is a sector-shaped corrugated steel plate, and the sector-shaped corrugated steel plate is uniformly distributed with a plurality of concentric Circular wave train, the trend of the wave train is parallel to the upper edge and the lower edge of the fan-shaped corrugated steel plate, and a plurality of "mouth" shapes or "mouths" are opened on the lower edge of the fan-shaped corrugated steel plate "shaped groove 6.

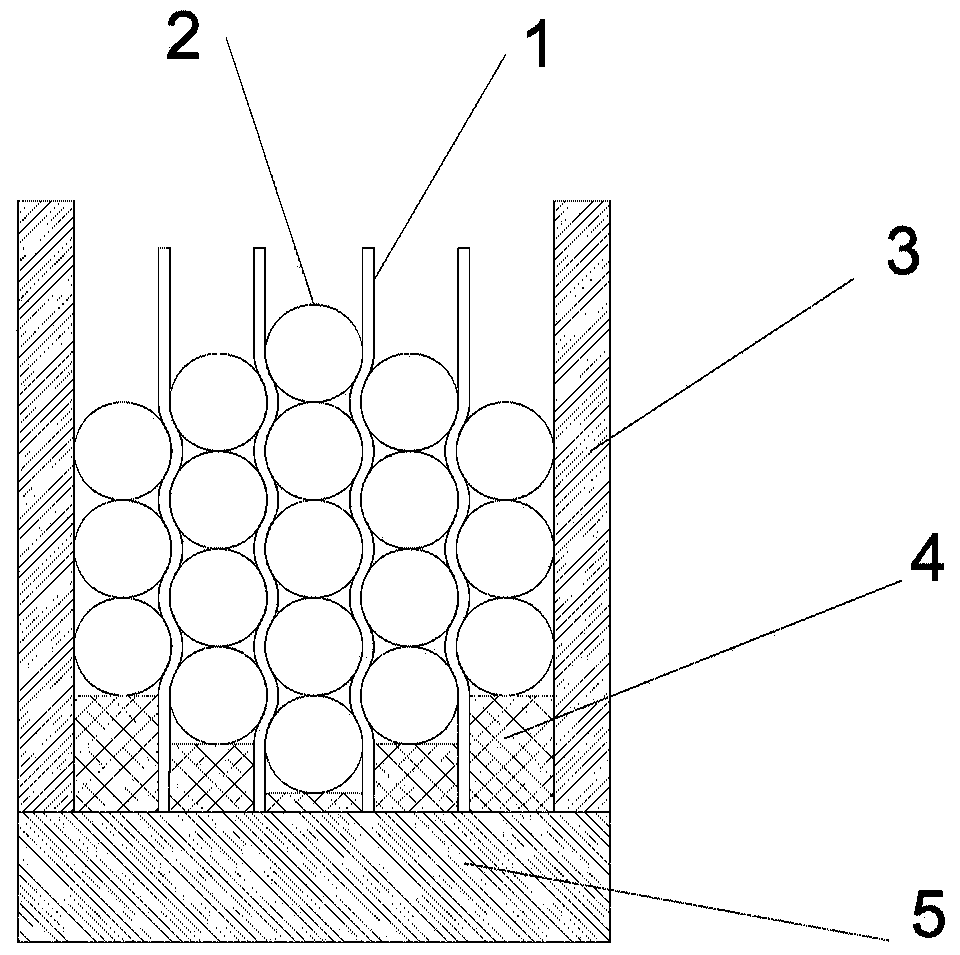

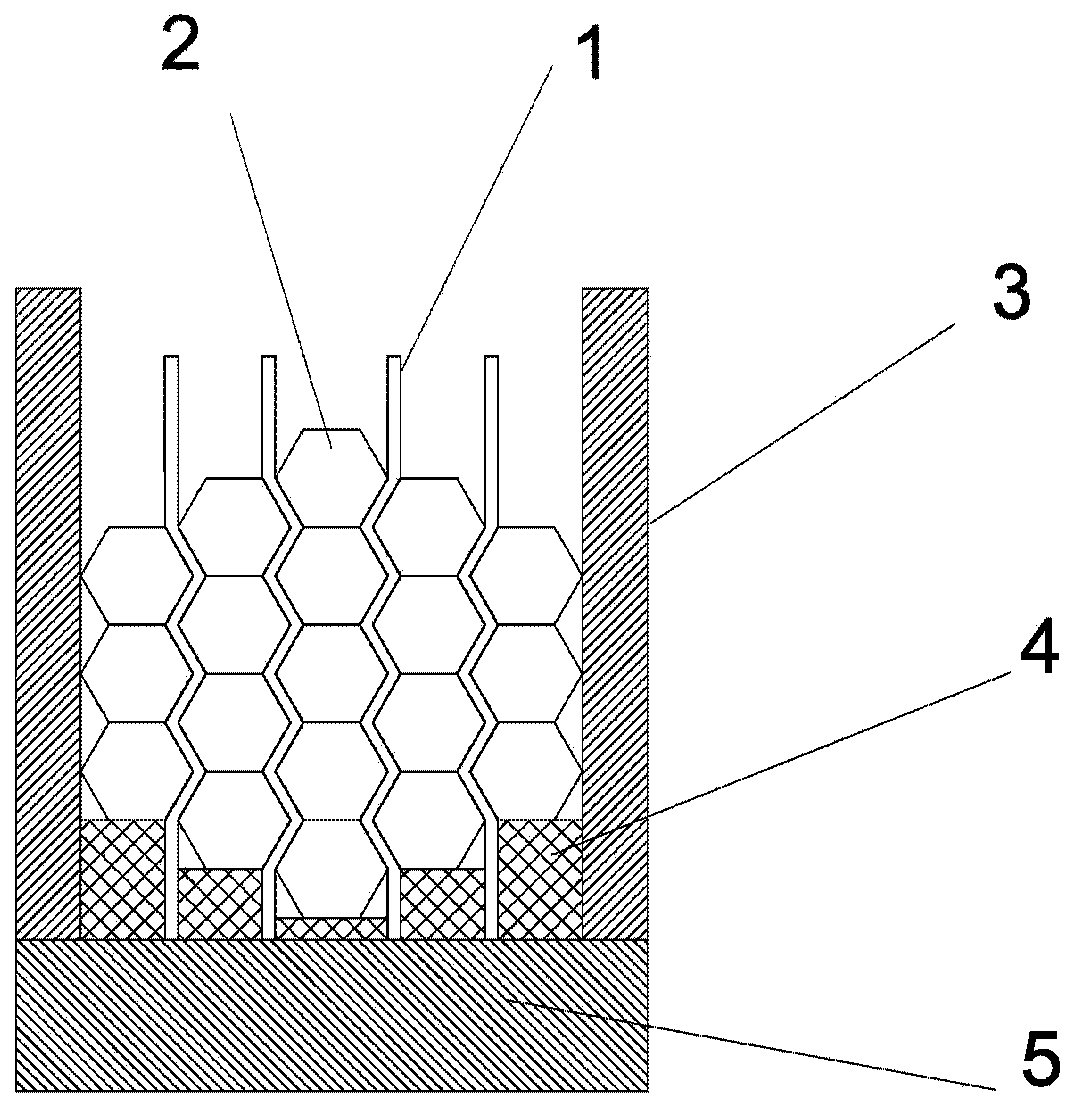

[0028] The lower edge of the fan-shaped corrugated steel plate is closely attached to the arc top surface of the saddle groove 5, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com