Double-sided intelligent embroidering machine

An embroidery machine and intelligent technology, applied in the field of embroidery, can solve problems such as low work efficiency, achieve the effects of convenient thread change, improved processing efficiency and processing quality, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

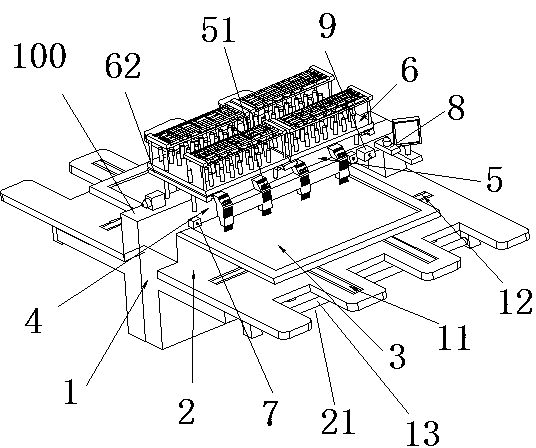

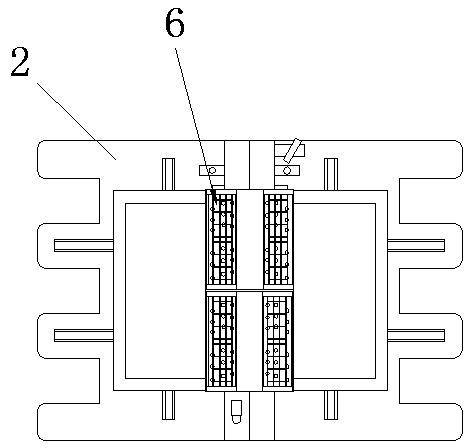

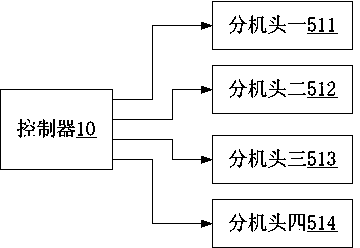

[0031] Such as Figure 1-7As shown, as an embodiment of the present invention, a double-sided intelligent embroidery machine includes a control system 10, a frame 1 and an embroidery unit, and the embroidery unit includes a workbench 2 on the frame 1 and a workbench 2 on the workbench 2. The embroidery frame 3 and the embroidery unit 4, the embroidery unit 4 includes a group of machine heads 5 fixed on the beam 100 of the frame 1 and a group of wire frames 6 for supplying thread to the machine heads 5, the embroidery unit 4 is There are two embroidery units, and the two embroidery units are arranged symmetrically on both sides of the cross beam 100 along the center line of the cross beam, and corresponding to each embroidery unit, there is also a stop brake lever 13 . The workbench 2 of the embroidery unit can be a split structure, that is, a workbench 2 is set corresponding to each embroidery unit. In this embodiment, the workbench 2 of the two embroidery units is integrated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com