Organic wastewater treatment device coupled with low-energy-consumption membrane biological reactor of microbial fuel cell

A technology for membrane bioreactor and organic wastewater treatment, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of inability to effectively remove suspended solids, difficulty in reusing effluent or Emissions and other issues, to achieve the effect of reducing construction costs, reducing operating costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

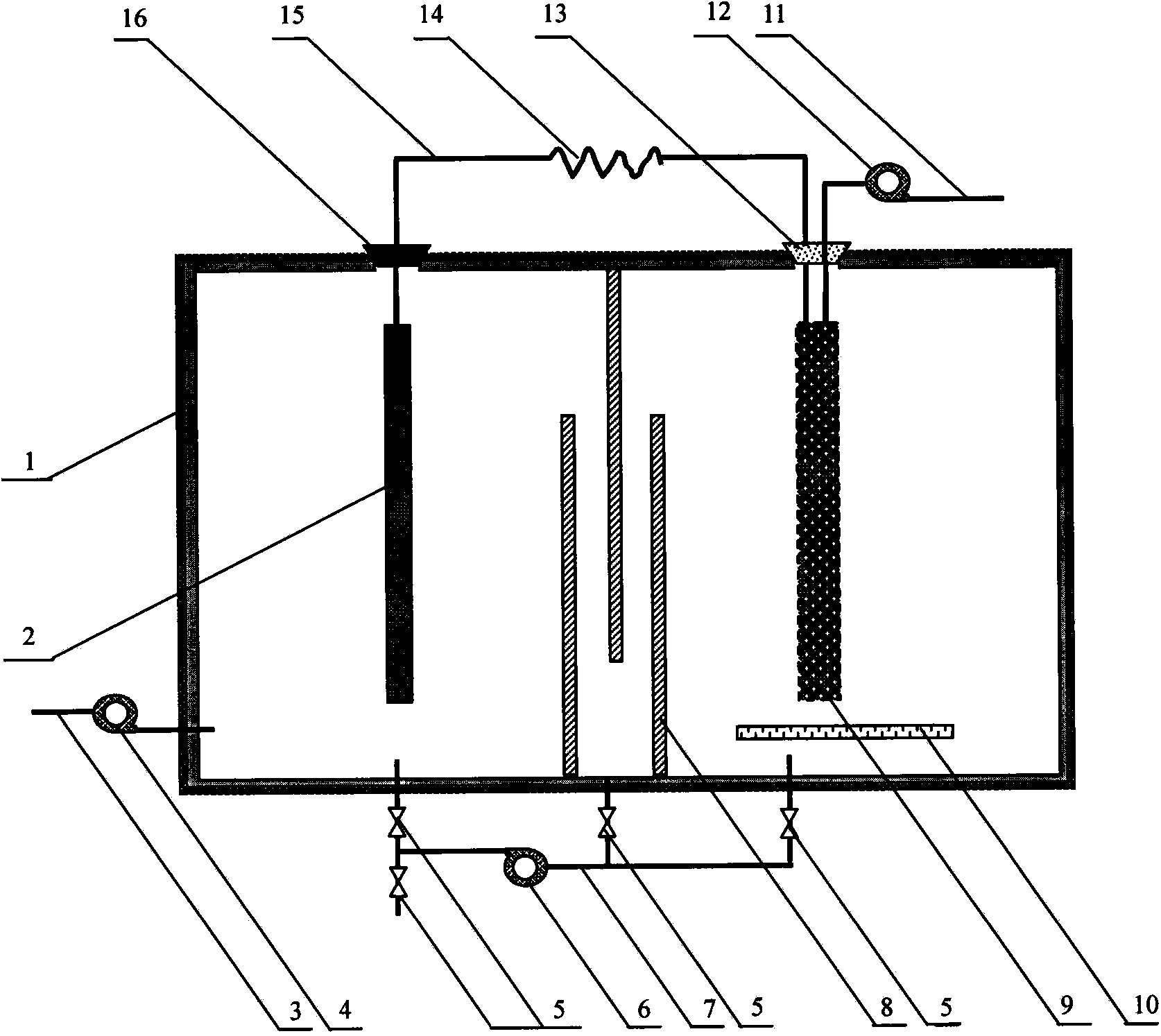

[0017] Example 1: MFC anode (2) adopts carbon felt, deflector (8) adopts 3 pieces of cross arrangement, MBR membrane module (9) and MFC cathode adopt graphene, polyvinylidene fluoride 1: 2 mixed modification non-woven fabric . The water quality of the system is as follows: COD concentration is 500mg / L, ammonia nitrogen is 20mg / L, and the pH value is 7; the HRT of the MFC anode chamber is 8h; the HRT of the baffle area is 10h, and the dissolved oxygen concentration is 0.2mg / L; the MBR unit The HRT is 6h, the dissolved oxygen concentration is 4.0mg / L; the temperature is 25°C.

Embodiment 2

[0018] Example 2: The MFC anode (2) is made of carbon cloth, the deflector (8) is arranged in five intersections, and the MBR membrane module (9) and the MFC cathode are made of polyaniline-modified stainless steel mesh. The water quality of the system feed water is as follows: COD concentration is 1000mg / L, ammonia nitrogen is 50mg / L, and the pH value is 8; the HRT of the MFC anode chamber is 10h; the HRT of the baffle area is 12h, and the dissolved oxygen concentration is 0.5mg / L; the MBR unit The HRT is 8h, the dissolved oxygen concentration is 2.0mg / L; the temperature is 30℃.

Embodiment 3

[0019] Example 3: The MFC anode (2) is made of graphite, the deflector (8) is arranged in 7 intersections, and the MBR membrane module (9) and the MFC cathode are made of graphene-modified carbon cloth. The water quality of the system inlet water is as follows: COD concentration is 10000mg / L, ammonia nitrogen is 2000mg / L, and the pH value is 9; the HRT of the MFC anode chamber is 22h; the HRT of the baffle area is 18h, and the dissolved oxygen concentration is 0.1mg / L; the MBR unit The HRT is 12h, the dissolved oxygen concentration is 6.0mg / L; the temperature is 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com