Precise linear shaft for cutter grinder

A tool grinding machine, linear axis technology, applied in the direction of manufacturing tools, grinding/polishing equipment, other manufacturing equipment/tools, etc., can solve the problems of slow processing speed, low processing accuracy, poor performance of the whole machine, etc. Improve, improve the processing speed, the effect of repeating the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

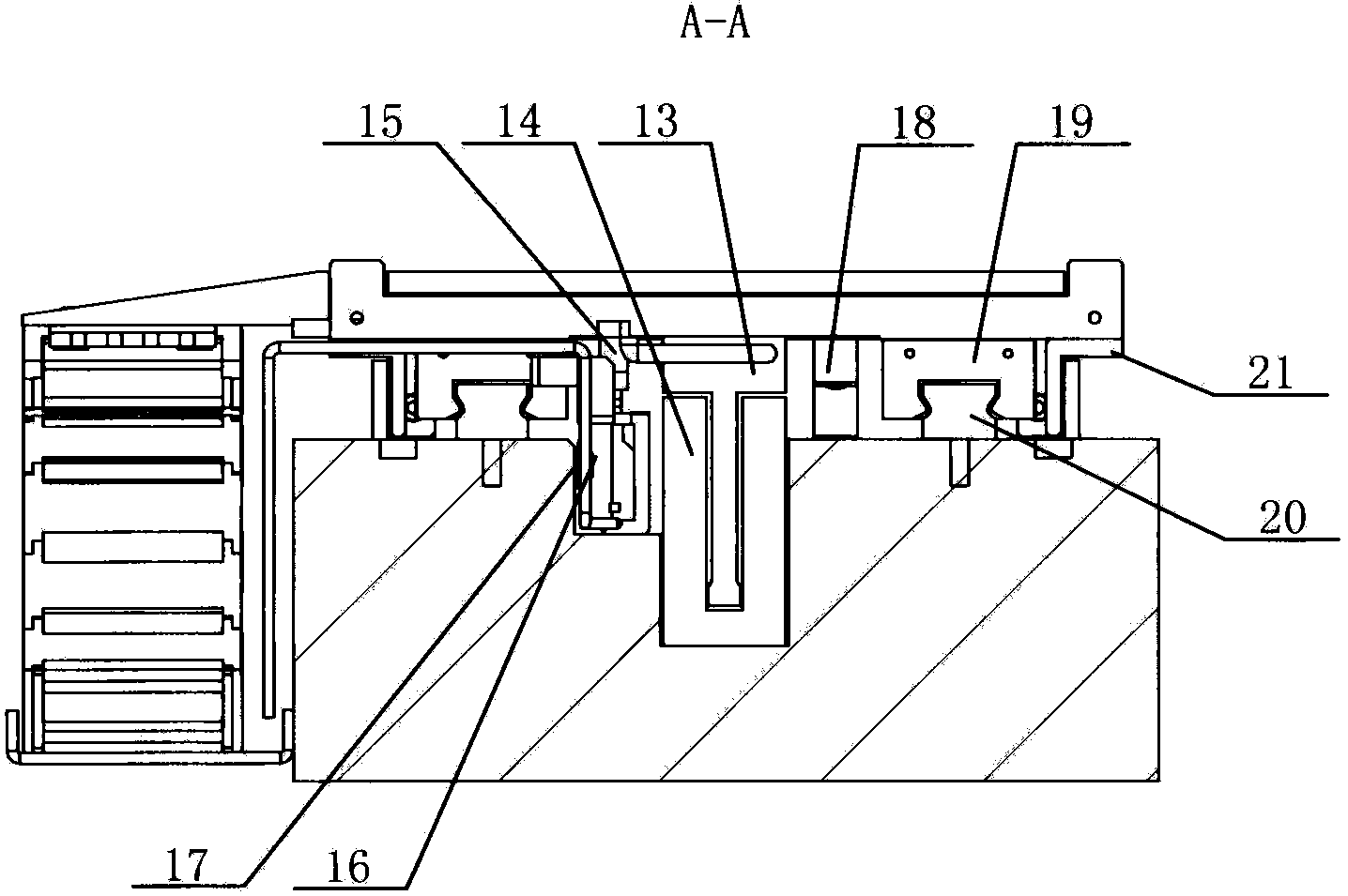

[0009] see figure 1 , figure 2 , the specific embodiment adopts the following technical solutions: it includes a base 1, a water retaining plate 2, an end plate 3, a protective plate 4, a left dust cover 5, a right dust cover 6, a moving plate 7, and a dust cover connecting plate 8 , drainage groove 9, external interface connecting plate 10, electrical interface 11, air pipe interface 12, linear motor rotor 13, linear motor stator 14, limit block 15, reading ruler 16, grating ruler 17, hard limit 18, slider 19 , guide rail 20, inner water retaining plate 21, the upper end of the base 1 is provided with a water retaining plate 2, the two ends of the base 1 are each provided with an end plate 3, the two end plates 3 are fixed with a protective plate 4 by bolts, and the water retaining plate 2 The upper end is provided with a left dust cover 5 and a right dust cover 6, and the right end of the left dust cover 5 and the left end of the right dust cover 6 are provided with a dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com