Pneumatic control rivet feeding mechanism for automatic rivet feeding riveting machine

A riveting machine and nail feeding technology, which is applied in the field of riveting equipment, can solve the problems of unsuccessful feeding, complex structural parts, high length of compression spring 7, etc., and achieve the effect of stable feeding and simple structural parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

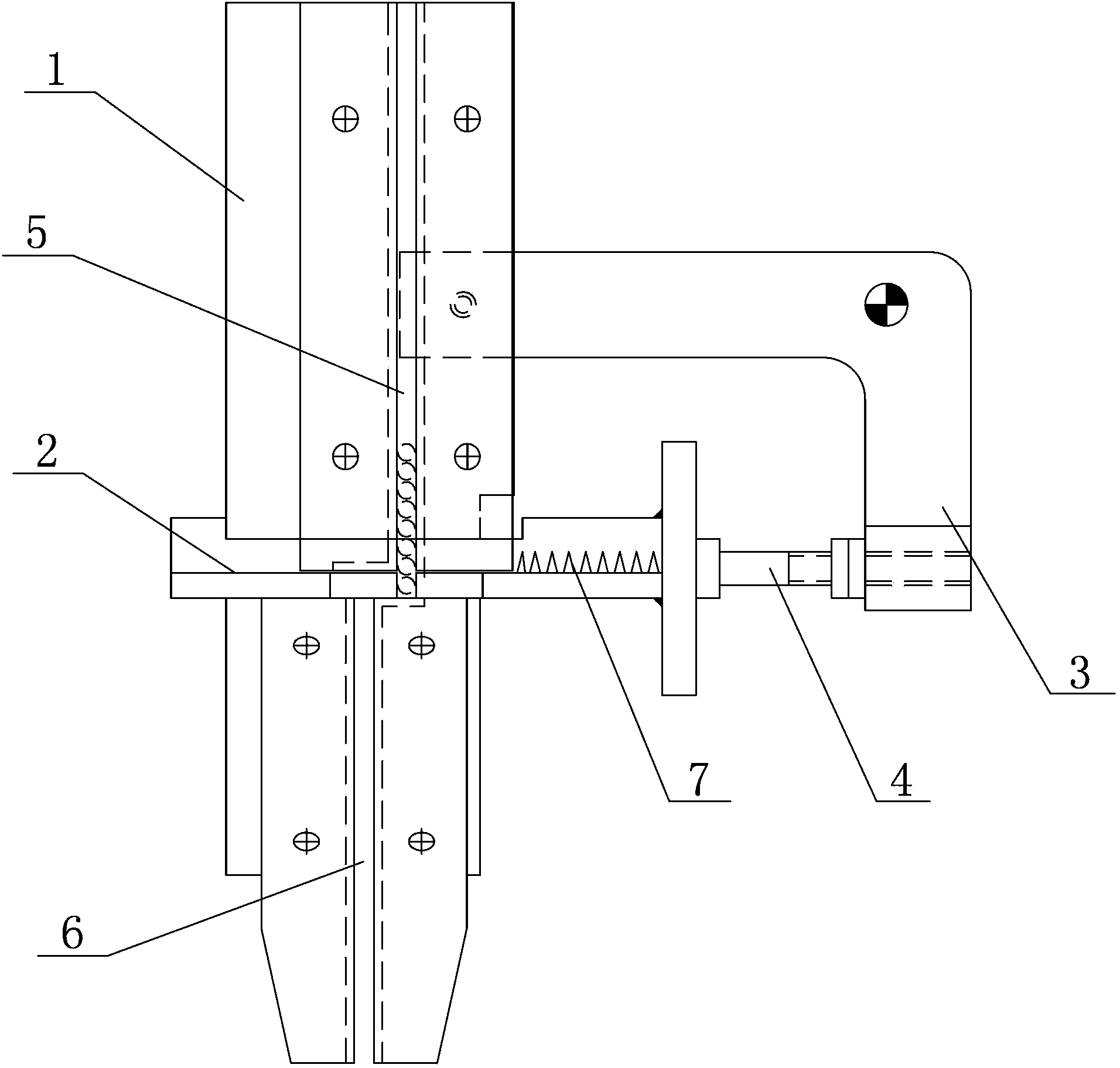

[0013] figure 1 The mechanical pendulum-type nail-feeding mechanism of the existing automatic nail-feeding riveting machine shown has been introduced in detail in the background art, and will not be repeated here.

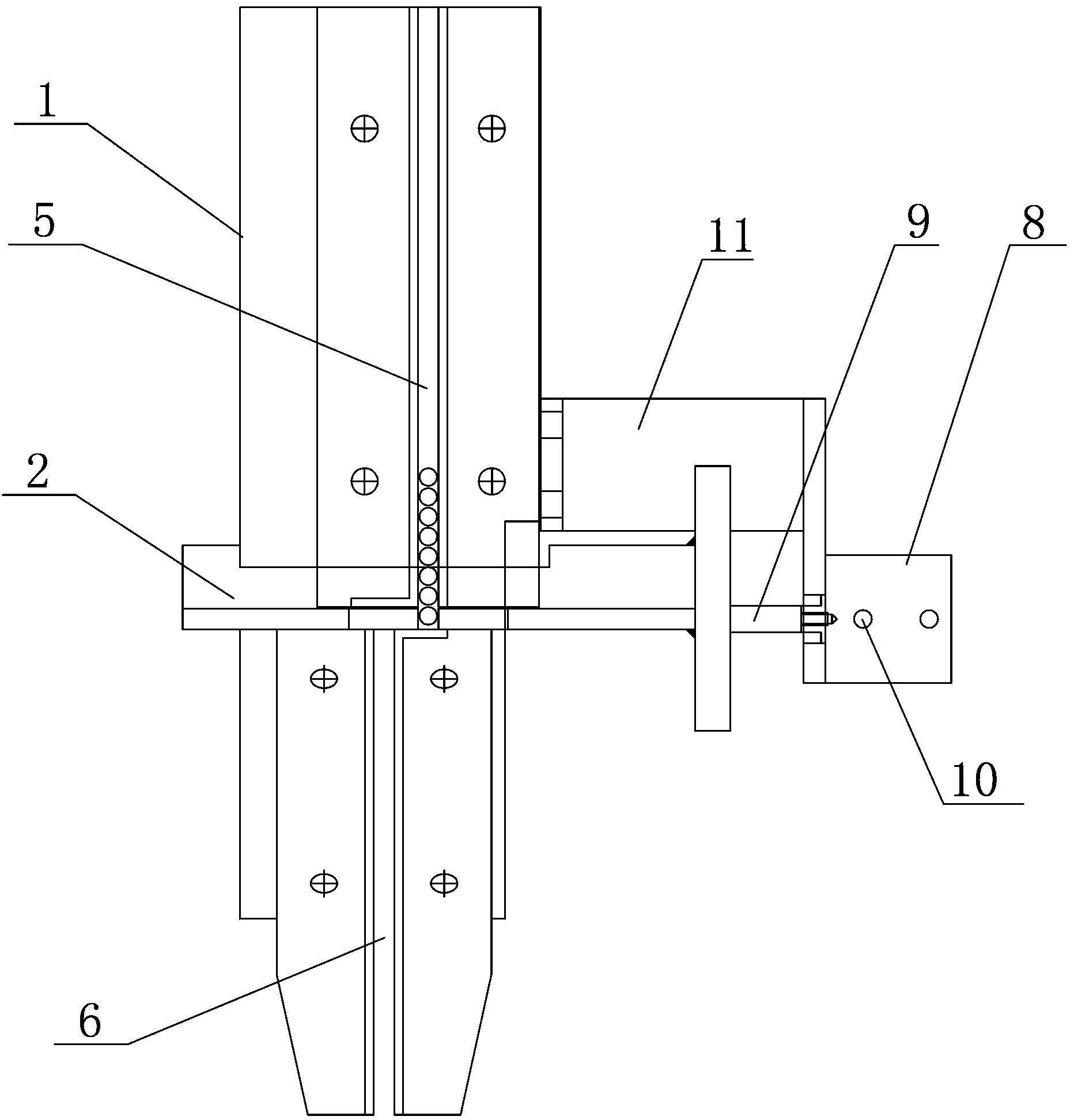

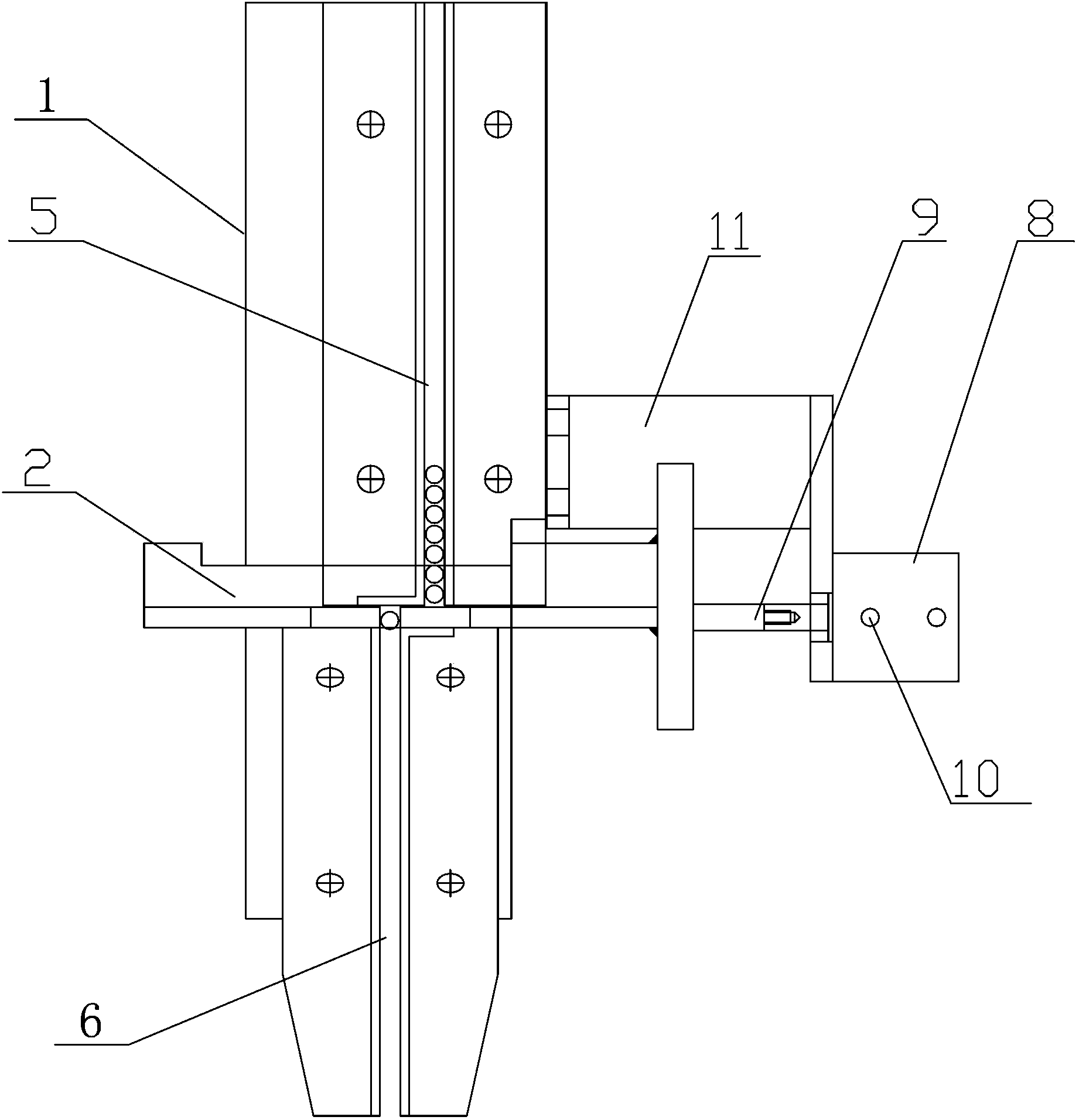

[0014] Figure 2~3 The air-controlled nail-feeding mechanism of the automatic nail-feeding riveting machine shown includes a bracket 1, a feeding rack 2, an upper guide rail 5 and a lower guide rail 6 located above and below the feeding rack 2, respectively. The side of feed frame 2 is provided with cylinder 8, and the piston push rod 9 of cylinder 8 is connected with the side end surface of feed frame 2, and the feeding direction of piston push rod 9 is parallel with feed frame 2. The cylinder 8 is connected to the bracket 1 through the cylinder bracket 11 , and the air cylinder 8 is provided with a ventilation hole 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com