Water storage system

A water storage container, water level technology, applied in the directions of dissolution, mixer, chemical instrument and method, can solve the problems of high water level overflow, low production efficiency, unfavorable market competition, etc., to prevent the water level from overflowing or being too low, The effect of improving the mixing uniformity and enhancing the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

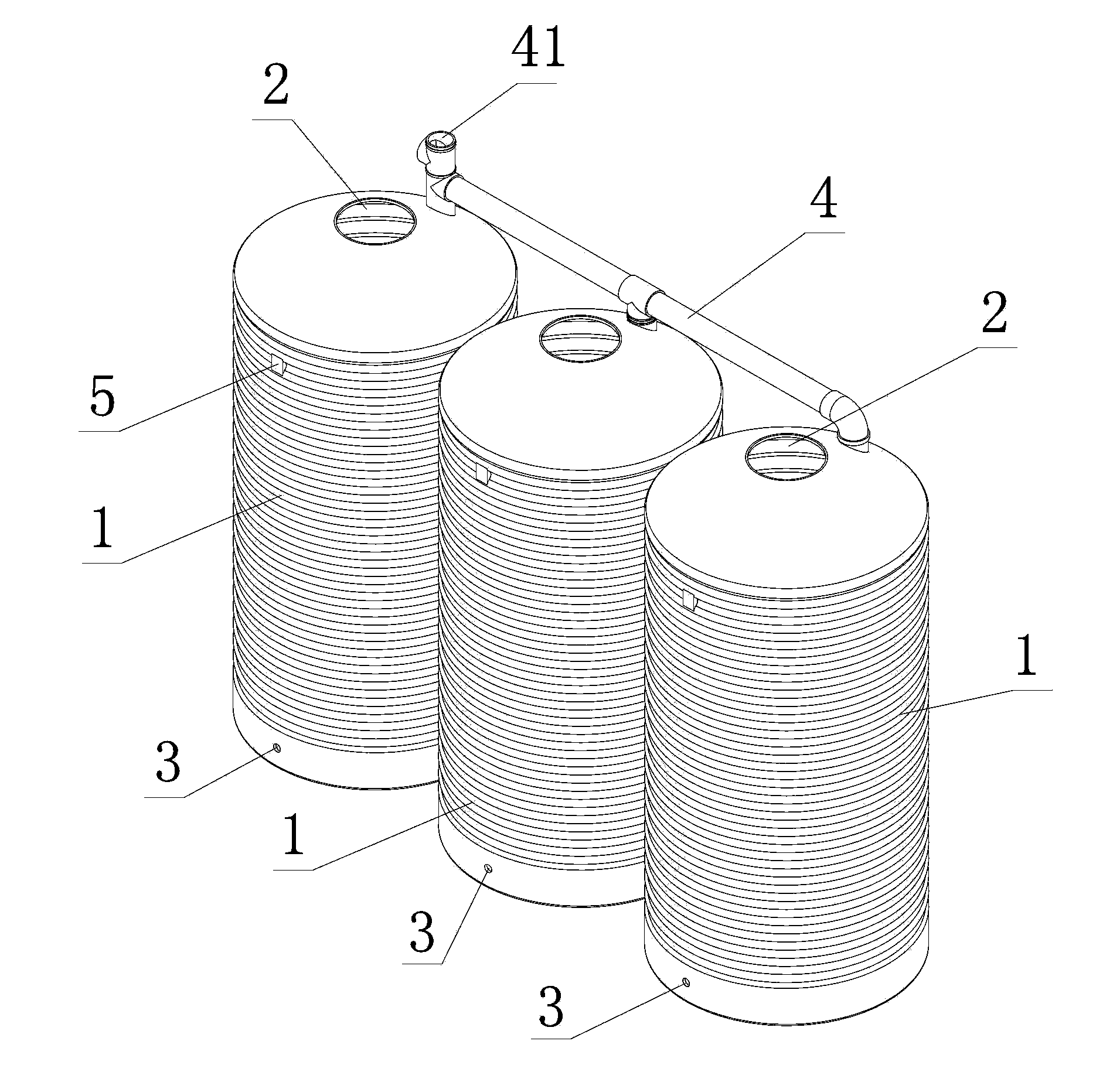

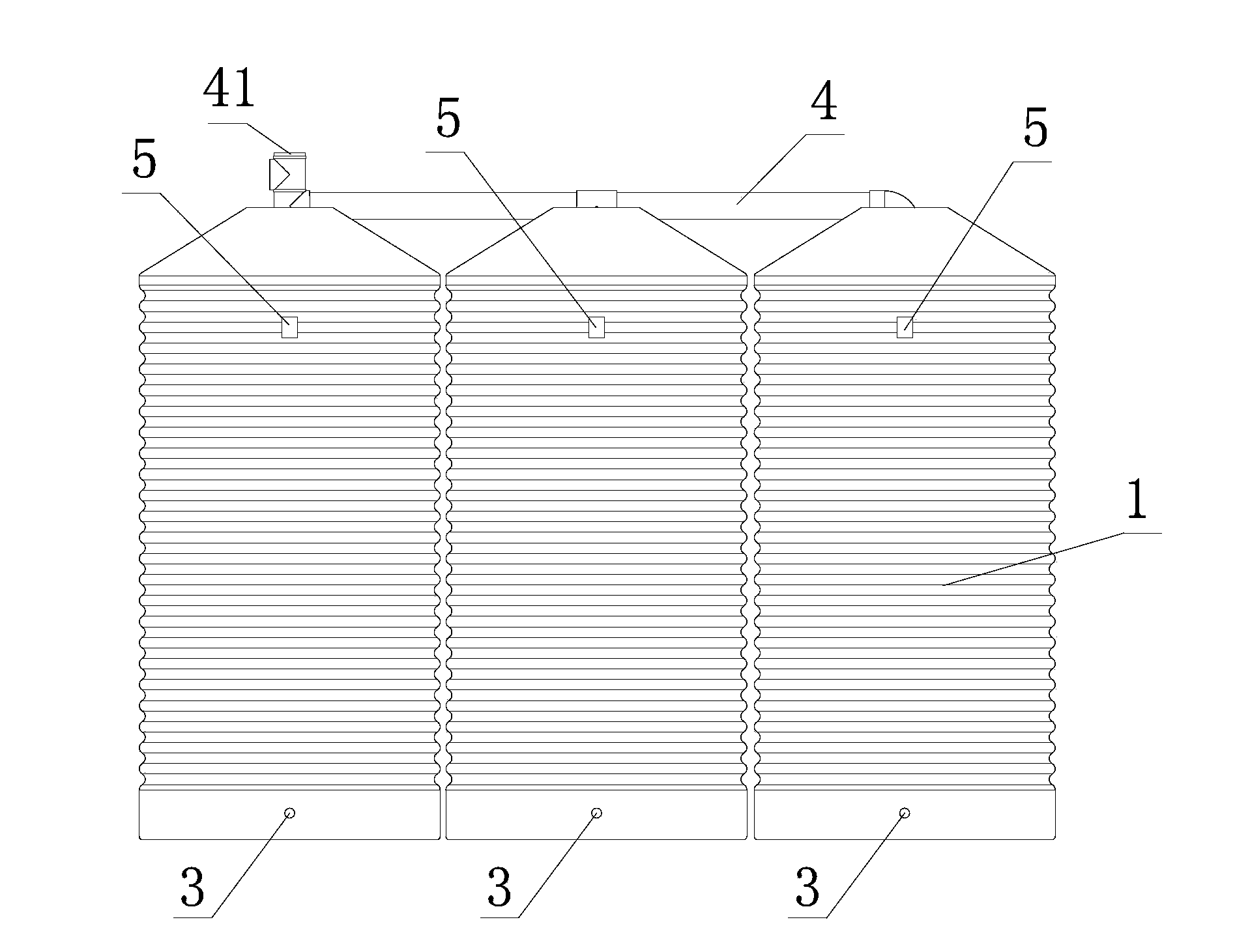

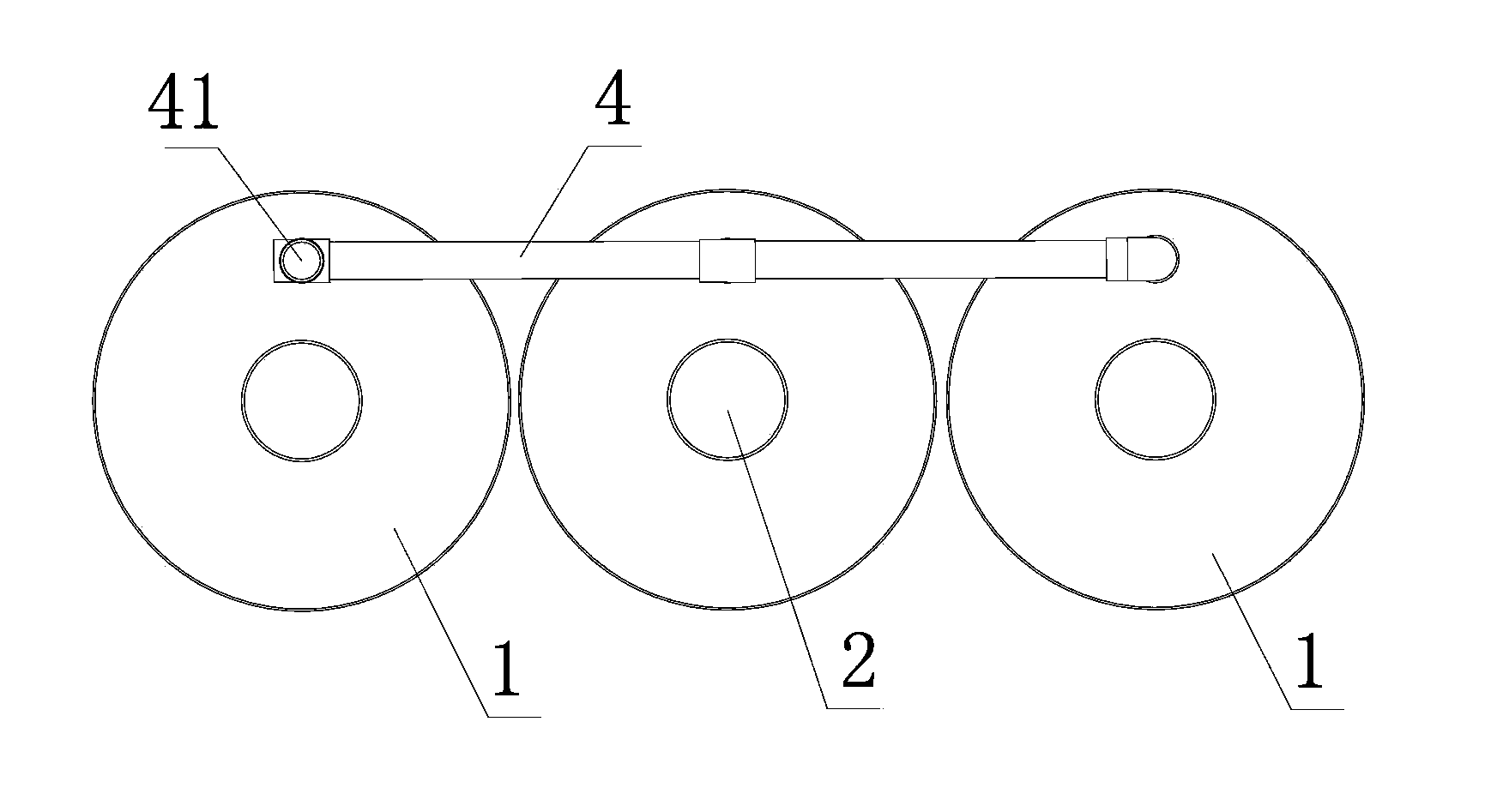

[0015] see figure 1 , figure 2 with image 3 , the present embodiment provides a water storage system, which includes three vertical water storage containers 1 arranged in a "one" shape. In other embodiments, it can be set according to the type of mixed liquid and each mixing parameter The quantity of water storage container 1 can be arranged, and this water storage container 1 can be arranged in triangle or other shape, to meet the demand of each place. The top of the water storage container 1 is provided with a water inlet 2, and the bottom is provided with a water outlet 3, and one side of the water inlet 2 is provided with a through pipe 4 that can connect the water storage container 1 with the adjacent water storage container 1, And the through pipe 4 is provided with a water inlet 41, which can inject liquid from the water inlet 2 and the water inlet 41 at the same time, saving working time. If it is necessary to produce different products or mix other liquids, other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com