Mounting fixture

A technology of fixtures and mounting pieces, applied in the direction of support structure installation, etc., can solve the problems of rectangular frame deformation, inability to install, squeezing servers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

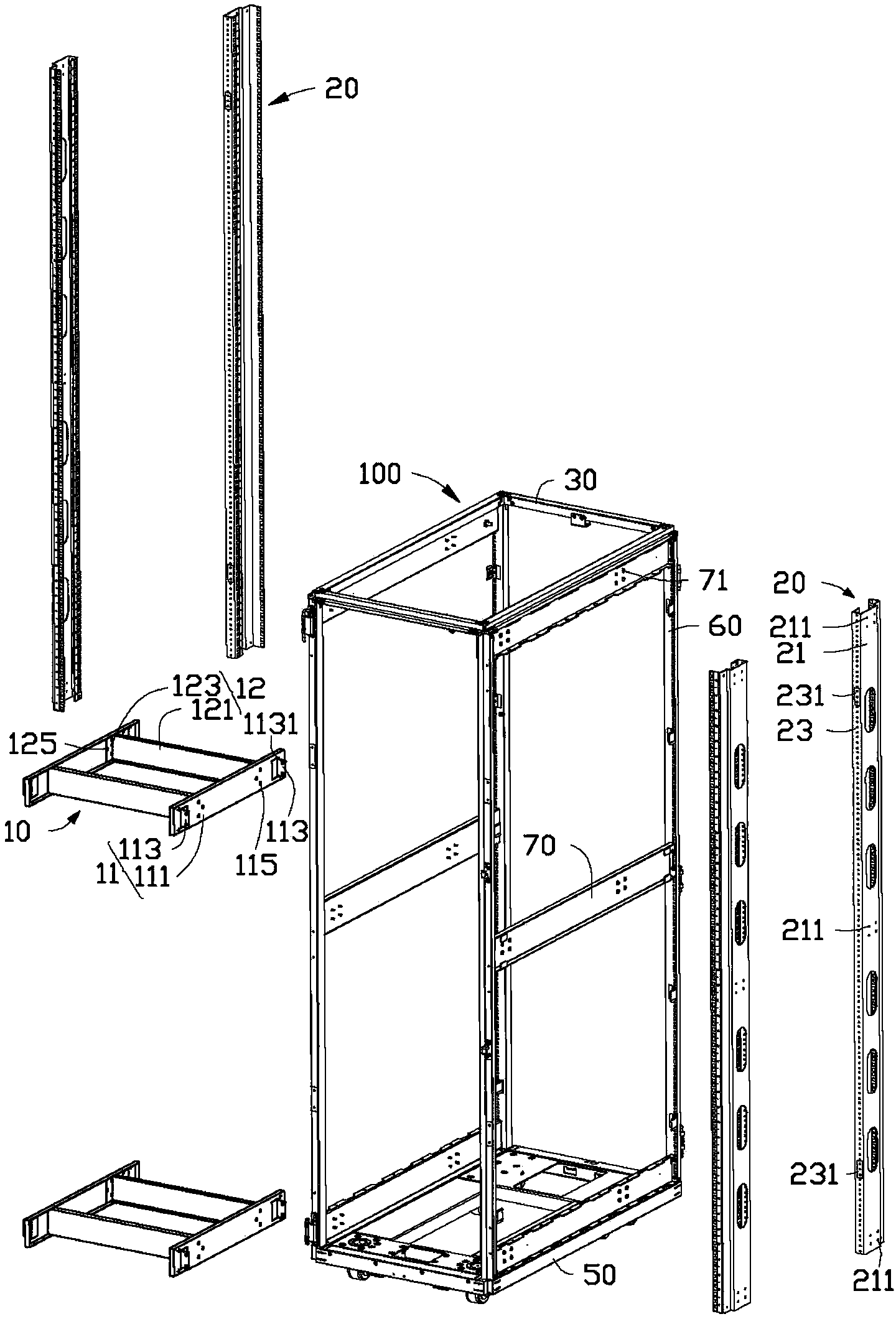

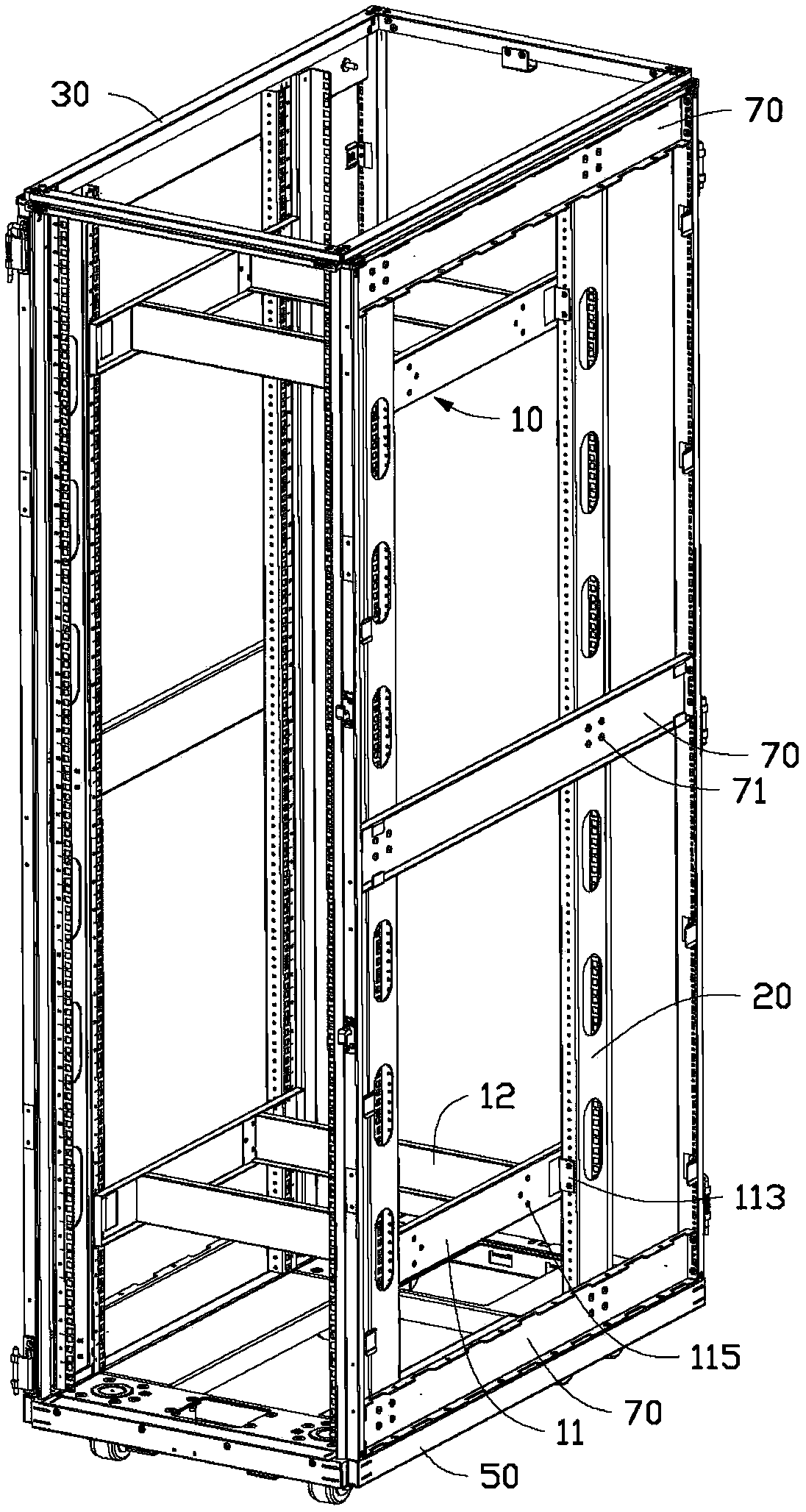

[0020] Please refer to figure 1 In a preferred embodiment of the present invention, two installation fixtures 10 are used to install four uprights 20 in a cabinet 100.

[0021] Each installation jig 10 includes two first positioning plates 11 and two second positioning plates 12. Each first positioning plate 11 includes a first plate 111 and a mounting piece 113 extending vertically outward from the outer surface of the first plate 111. The first plate 111 defines two sets of first fixing holes 115. There are three first fixing holes 115 in each group, and they are connected to form a triangle. Each mounting piece 113 defines two first mounting holes 1131. Each second positioning plate 12 includes a second plate 121 and two locking pieces 123 that are bent perpendicularly from two ends of the second plate 121 respectively. Each locking piece 123 defines three second fixing holes 125 corresponding to a group of first fixing holes 115. The two first plates 111 are parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com