Power converter and cooling system thereof

A technology for power converters and heat dissipation systems, applied in electrical components, output power conversion devices, cooling/ventilation/heating transformation, etc., can solve problems such as high inverter cost and bulky inverter, and reduce production costs , Guarantee the effect of dissipating and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

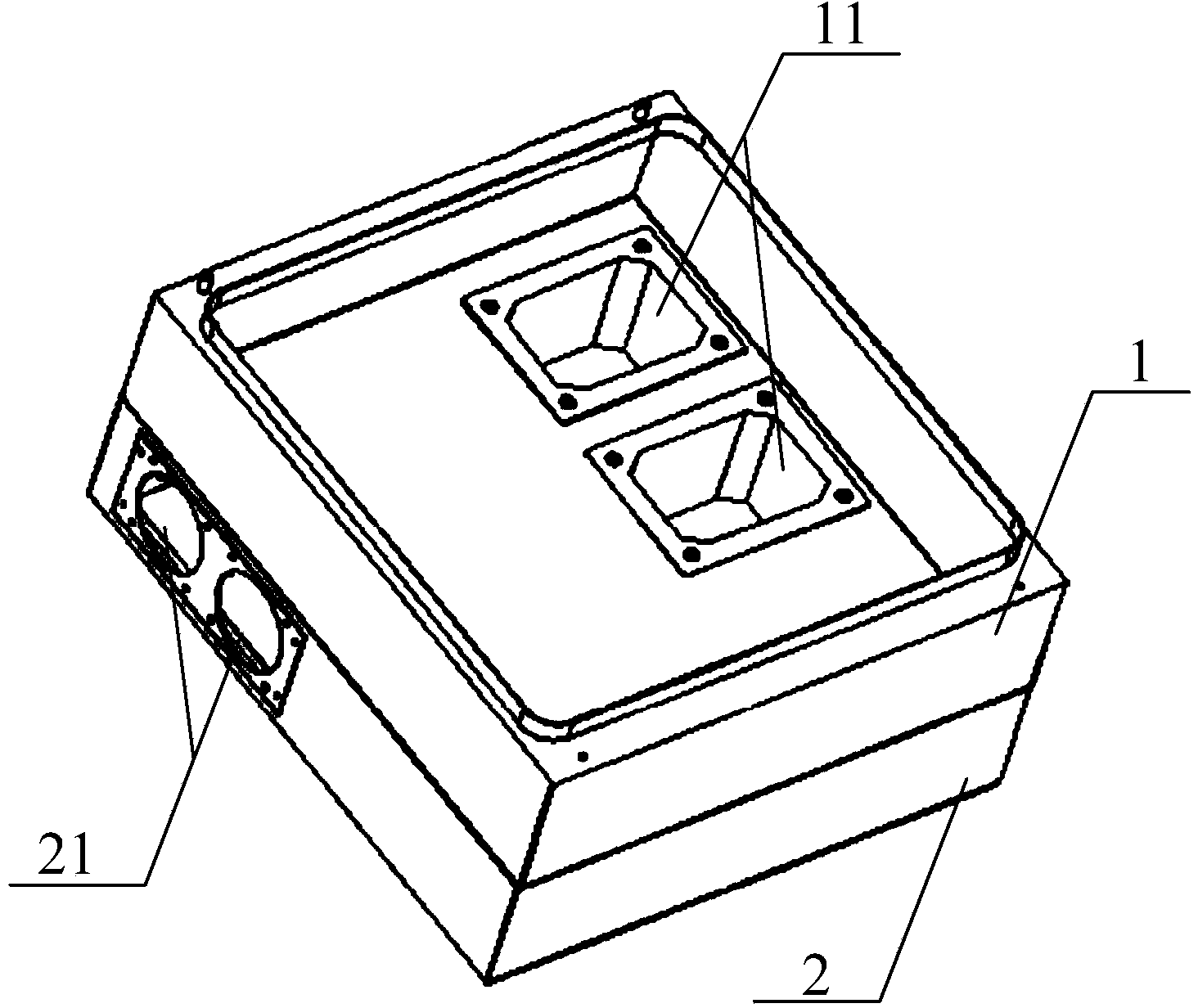

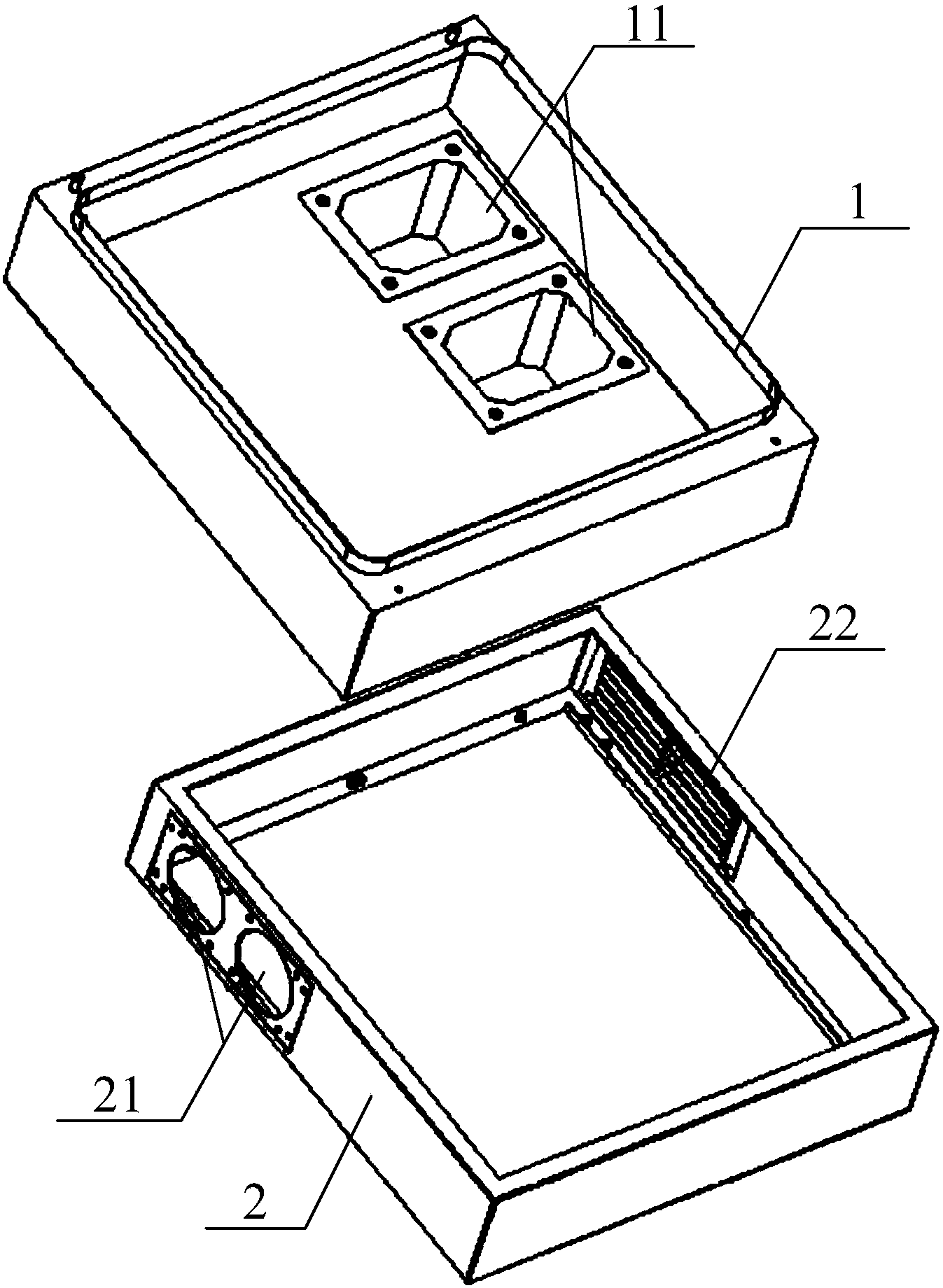

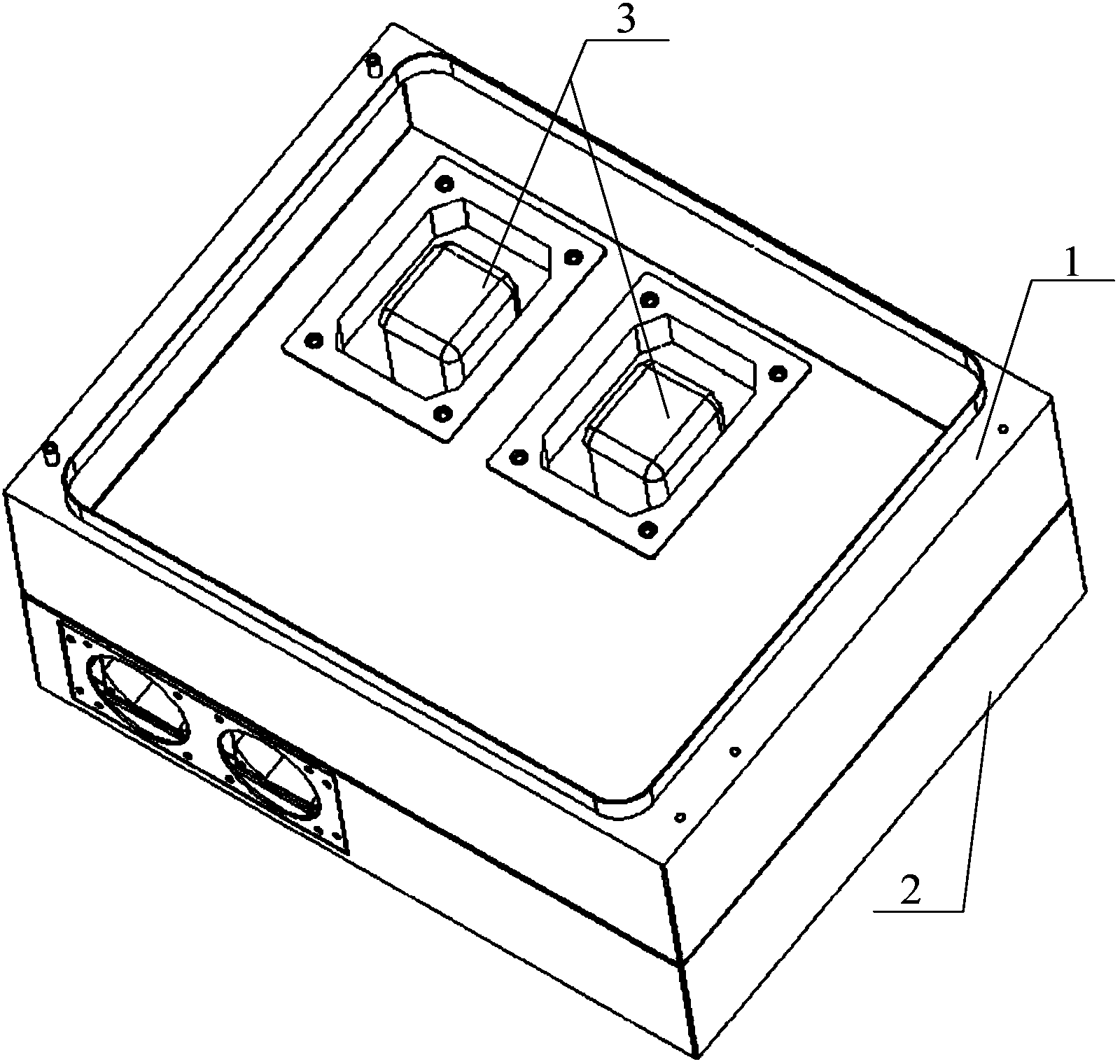

[0034] One of the cores of the present invention is to provide a heat dissipation system for a power converter, so as to effectively reduce the production cost of the power converter and the overall weight of the power converter while ensuring that the heat generated by the heating element is dissipated in time.

[0035] Another core of the present invention is to provide a power converter with the above heat dissipation system.

[0036] In order to enable those skilled in the art to better understand the solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] It should be noted that the essence of this solution has nothing to do with the type of the power converter. For the convenience of explanation, the embodiment of the present invention takes the inverter as an example for illustration, although only the inverter is given in this paper. embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com