Micro-assembly-oriented submicron precision coaxial confocal alignment detection method and device

A detection method and micro-assembly technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of inability to obtain the exact position and orientation information of parts in three-dimensional space, inability to complete the operation and assembly of structural parts, and lack of versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail in conjunction with accompanying drawing:

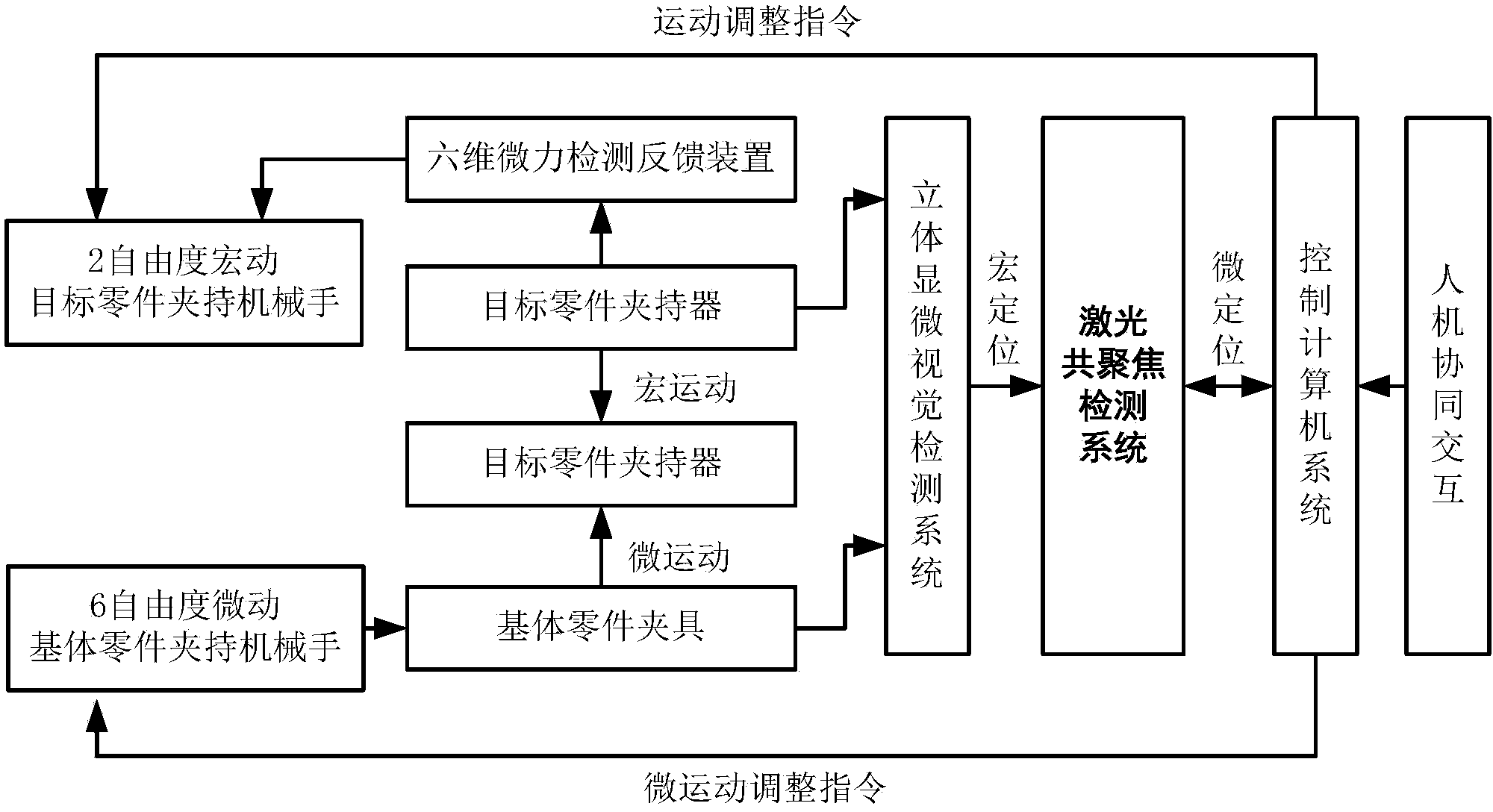

[0018] 1. Laser confocal coaxial precise alignment detection system

[0019] The overall block diagram of the laser confocal coaxial alignment detection system is as follows: figure 1 As shown, the target part clamping fixture of the macro-moving manipulator 1 and the base part clamping fixture of the micro-moving robot realize the final assembly of the micro-device. Both robot 1 and robot 2 are controlled by the main control computer. The manipulator of the target part can realize a wide range of macro-movements, from the position of the feeding mechanism to the initial position of the assembly alignment. This part mainly adopts the ordinary micro-optical system. The optical system can realize a large detection field of view, and realize the initial alignment and positioning of the target part and the base part under the condition of a large field of view. The traditional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com