Boiler having a fluidized bed heat exchanger

A heat exchanger, fluidized bed technology, applied in fluidized bed heat exchangers, heat exchange equipment, fluidized bed combustion equipment, etc., can solve problems such as good execution without difficulty

Active Publication Date: 2014-06-04

GENERAL ELECTRIC TECH GMBH

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this solution requires great construction skills to install all the different parts of the fluidized bed heat exchanger without gaps and without difficulties afterward to evaluate the good execution of the work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

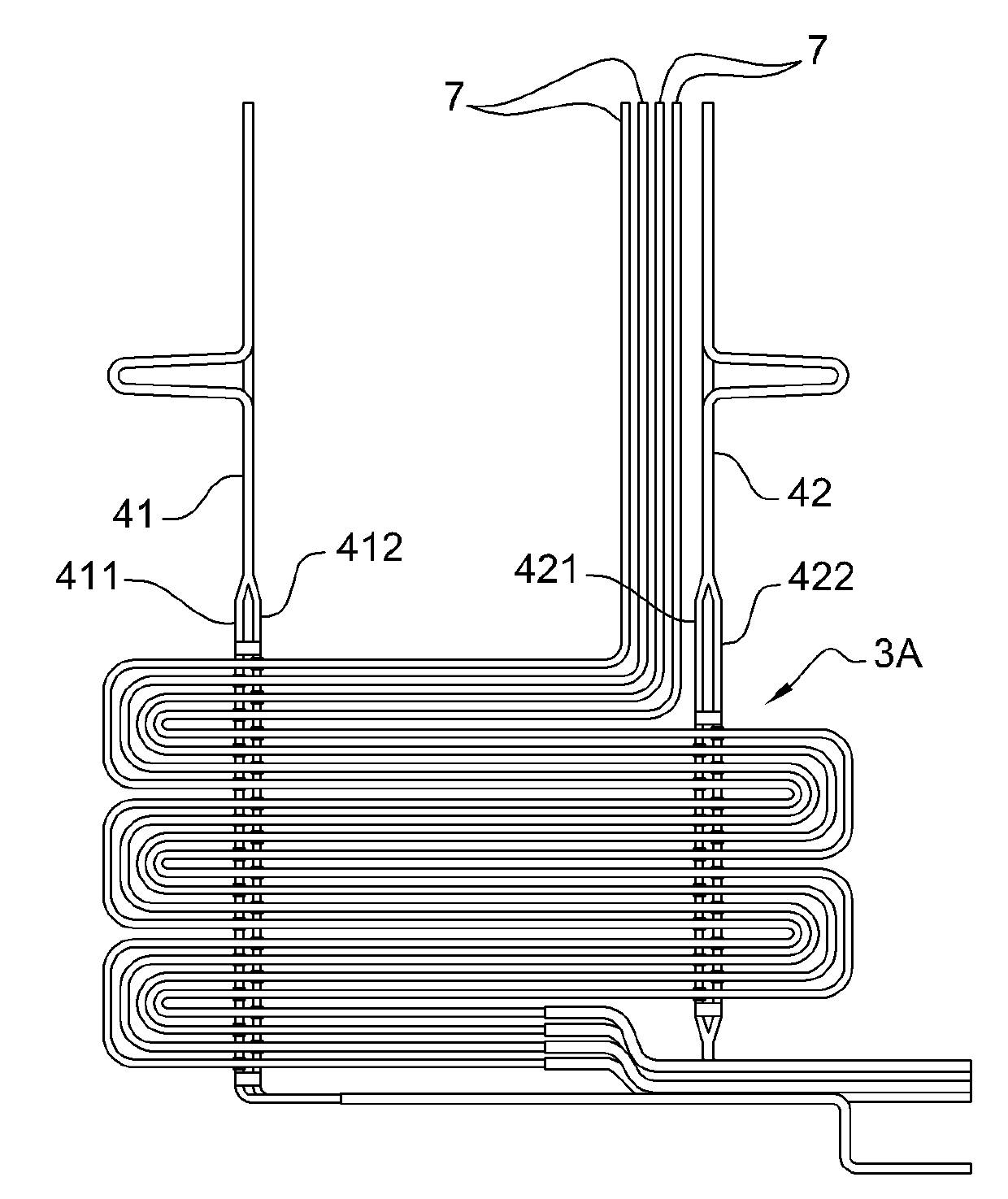

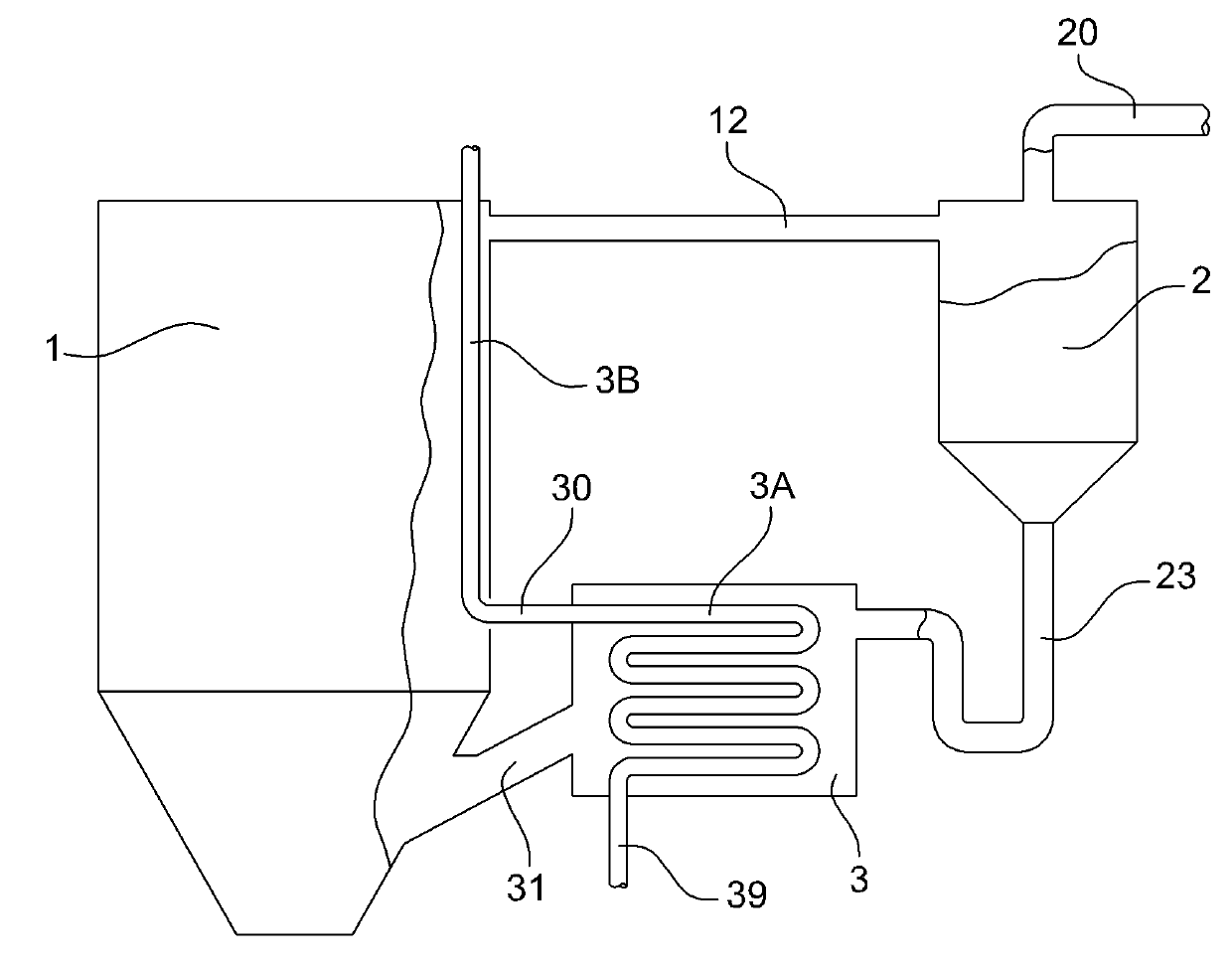

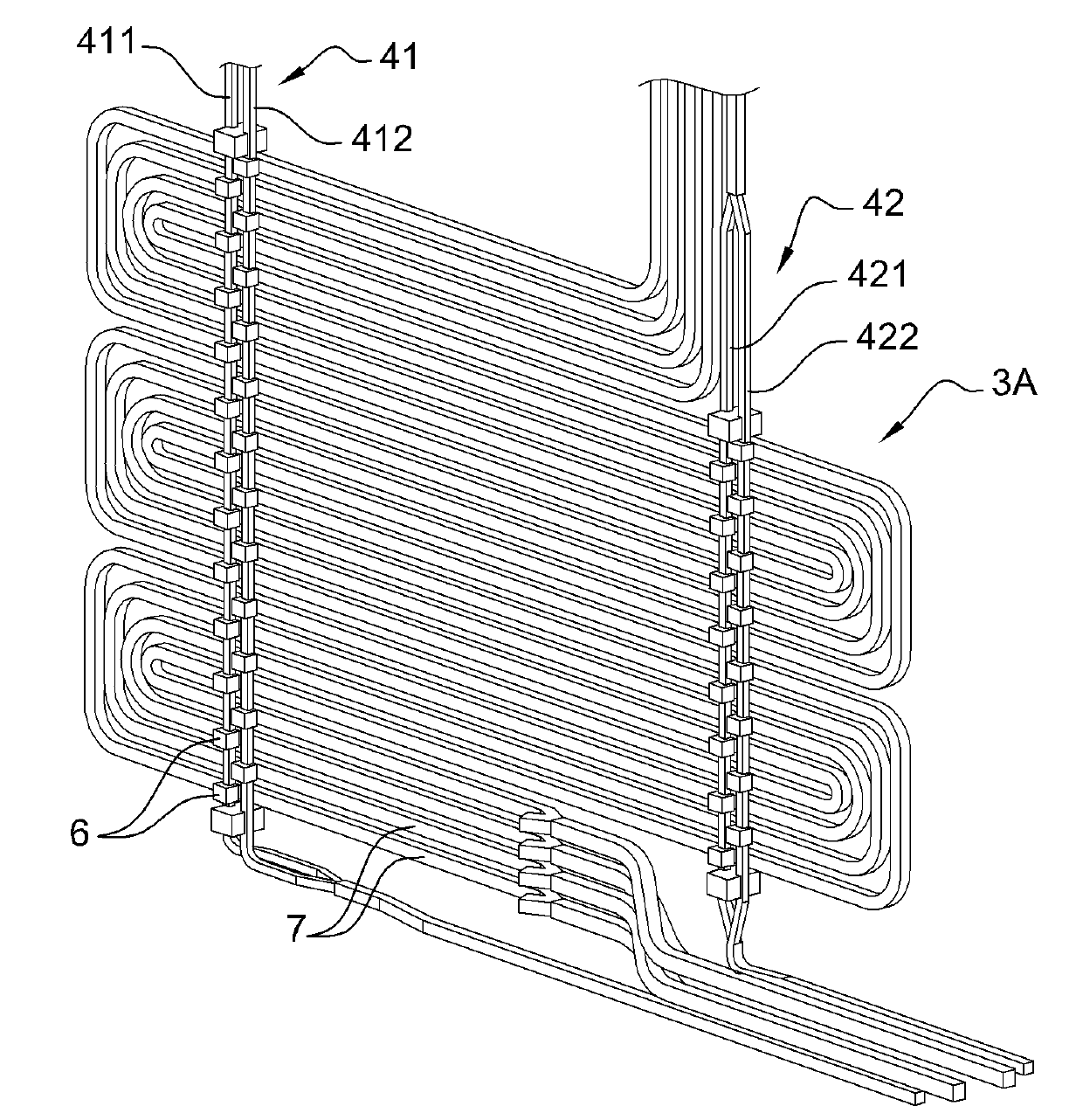

The invention refers to a boiler having a fluidized bed heat exchanger. The invention relates to a fluidized bed heat exchanger (3A), the heat exchanger (3A) including a plurality of tubes (7) forming a tube bundle, each tube (7) following a vertical boustrophedon path, the tubes (7) being supported by at least two vertical supporting devices (41,42) placed on both sides of the tube bundle, characterized in that every vertical supporting device (41,42) comprises at least two vertical supports (411,412;421,422) for fixing the tubes (7).

Description

technical field The present invention relates to boilers, typically circulating fluidized bed boilers (CTB), which include fluidized bed heat exchangers. A circulating fluidized bed boiler comprises a reactor in which solid particles are fluidized and in which chemical and / or combustion reactions can take place. Circulating fluidization enhances particle mixing and potentially exothermic or endothermic chemical reactions. Background technique The principle of operation of a fluidized bed heat exchanger is relatively simple: hot solids are brought into a chamber where they are gasified by air or a recirculation flue into a slowly bubbling fluidized bed. A heat exchanger element (usually in the form of a coil following a right-hand left-hand alternate writing path) is located inside the fluidized bed and is supplied with coolant fluid. The coil must be held by supports. It is known to use a sliding connection to the support, allowing differential movement between the tube ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23C10/00F23C10/18

CPCF22B37/203F28F9/013F22B21/34F22B31/0092F22B37/205F28D7/082F28D13/00

Inventor F.卡鲁兹C.恩奧特A.夸兰塔T.格里伊

Owner GENERAL ELECTRIC TECH GMBH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com