Spill plate of coal mining machine

A technology of coal retaining plate and shearer, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of poor coal retaining effect, complex mechanism, high energy consumption, etc., achieve good coal loading effect, low energy consumption, Easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

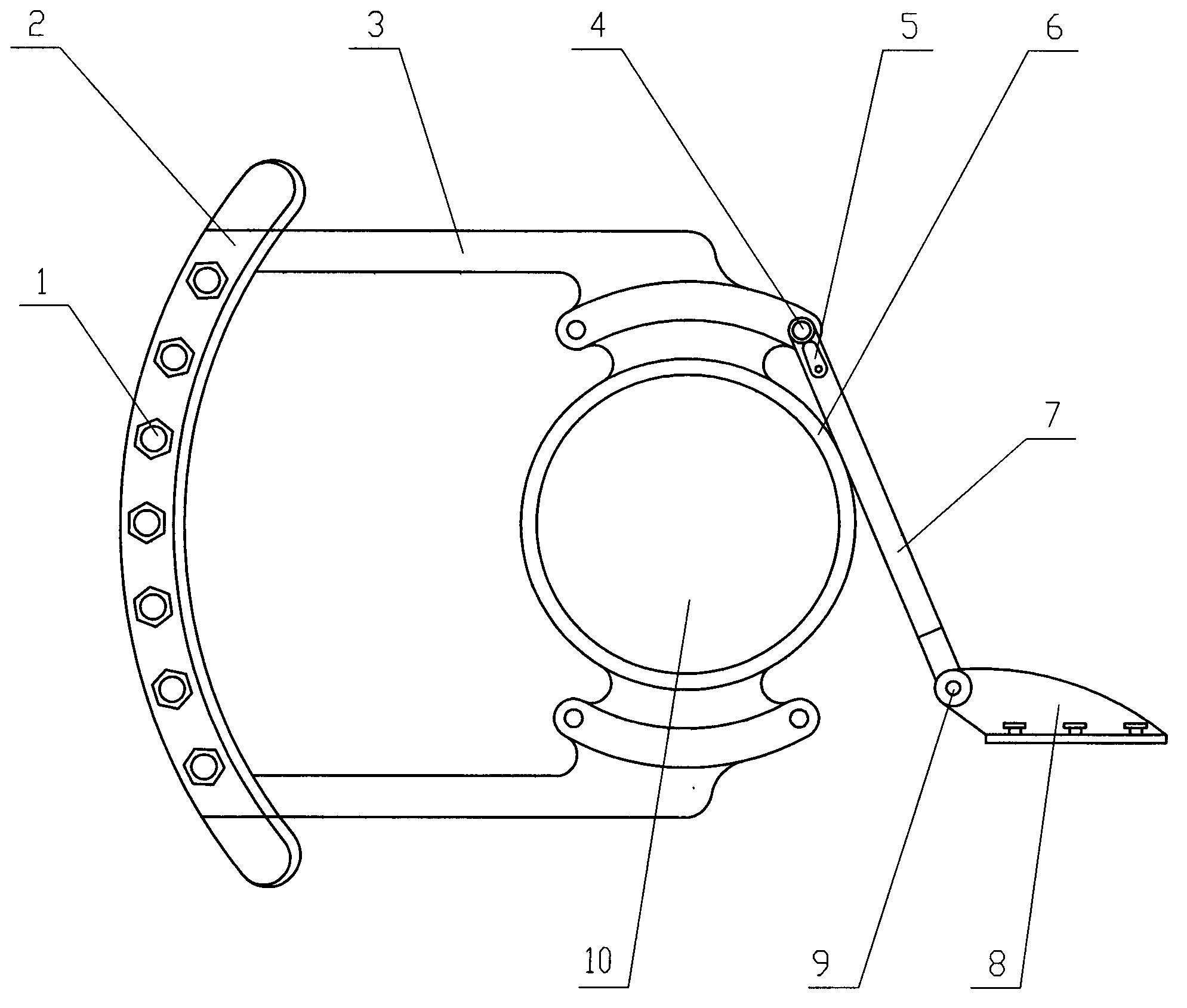

[0012] see figure 1 , The present invention includes a body 10, a bracket 3 on the body 10, the body 10 is connected to a support 8 by a connecting rod 7, and the bracket 3 is fixedly connected to the arc plate 2 by a screw 1 for easy replacement; the body 10 is fixedly connected to a gland 6. One end of the connecting rod 7 is rotatably connected with the support 8 via a pin 9, and the other end of the connecting rod 7 is rotatably connected with the body 10 via a pin 4; the connecting rod 7 and the body 10 are provided with a lug 5.

[0013] The connecting rod mechanism formed by the bracket, the arc plate and the connecting rod of the present invention enables the arc plate to move parallel to the bottom plate at any height of the drum within the adjustment range, so as to adapt to the work of the shearer and ensure a good coal loading effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com