Construction method and special hole forming machine of concrete cylinder buried in soft foundation

A concrete and soft foundation technology, applied in earthwork drilling, infrastructure engineering, liquid/gas jet drilling, etc., can solve the problems of long construction hours, high equipment requirements, and high equipment cost of concrete cylinders, and achieve easy compression , increase the construction depth, improve the effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

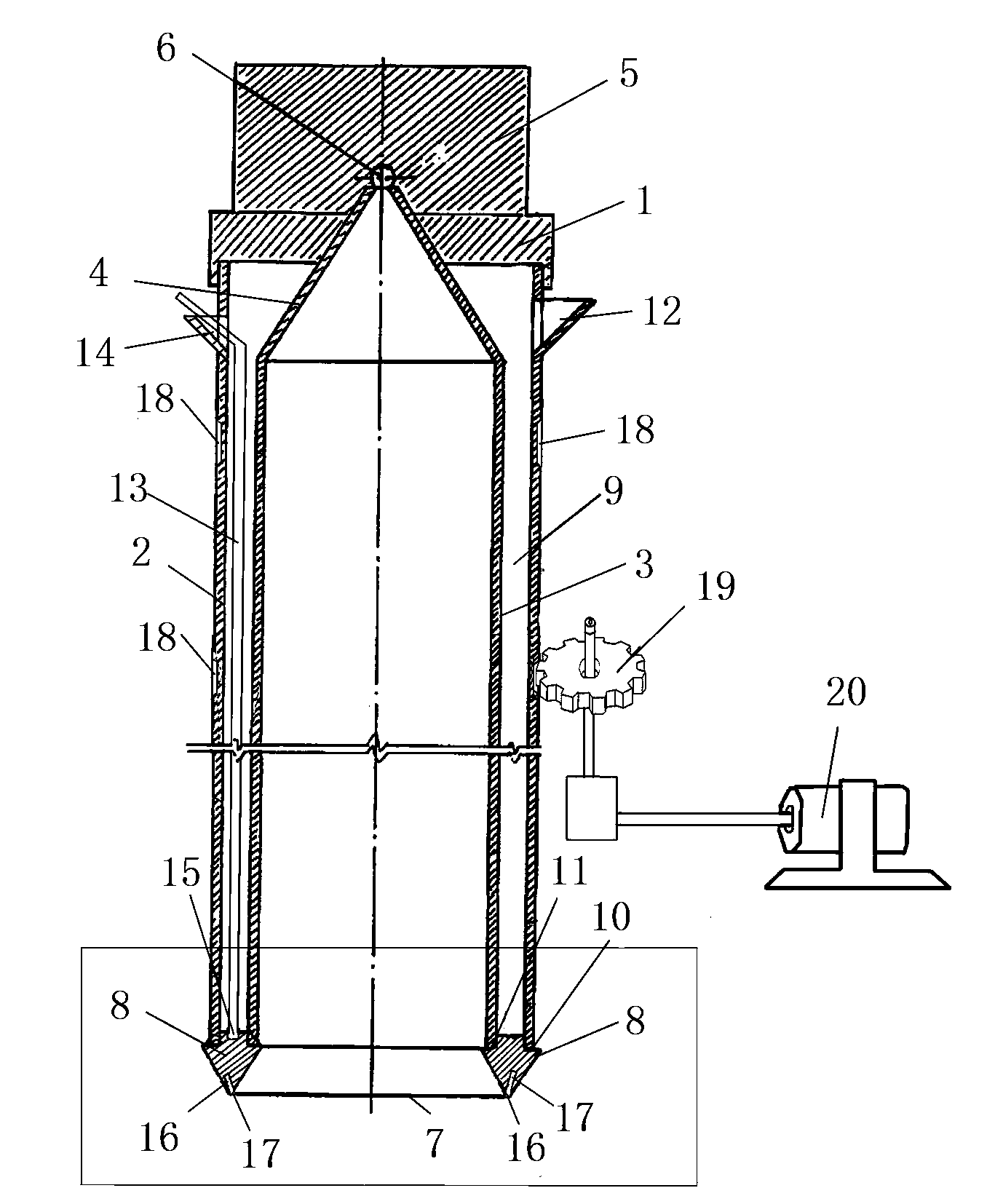

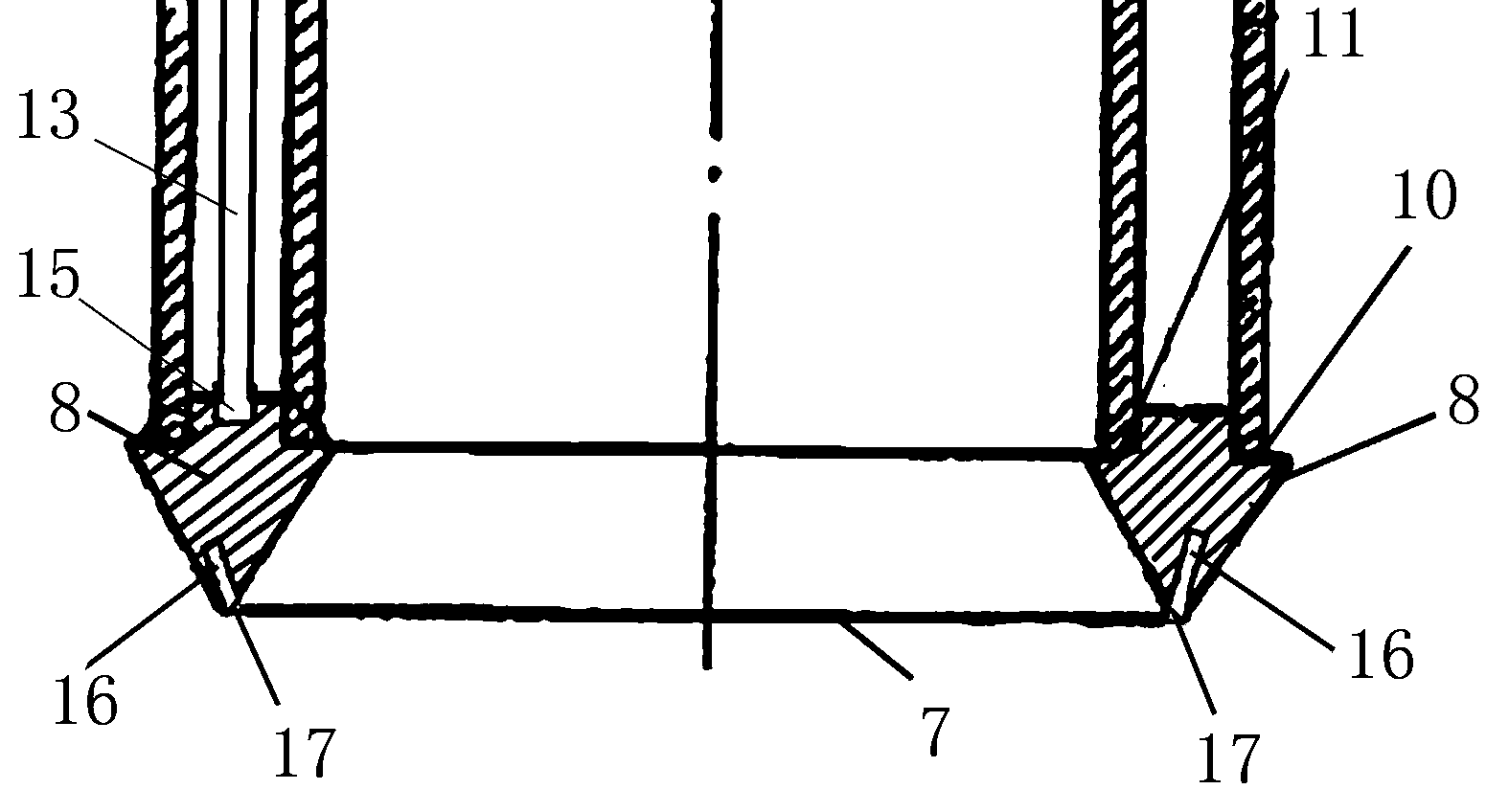

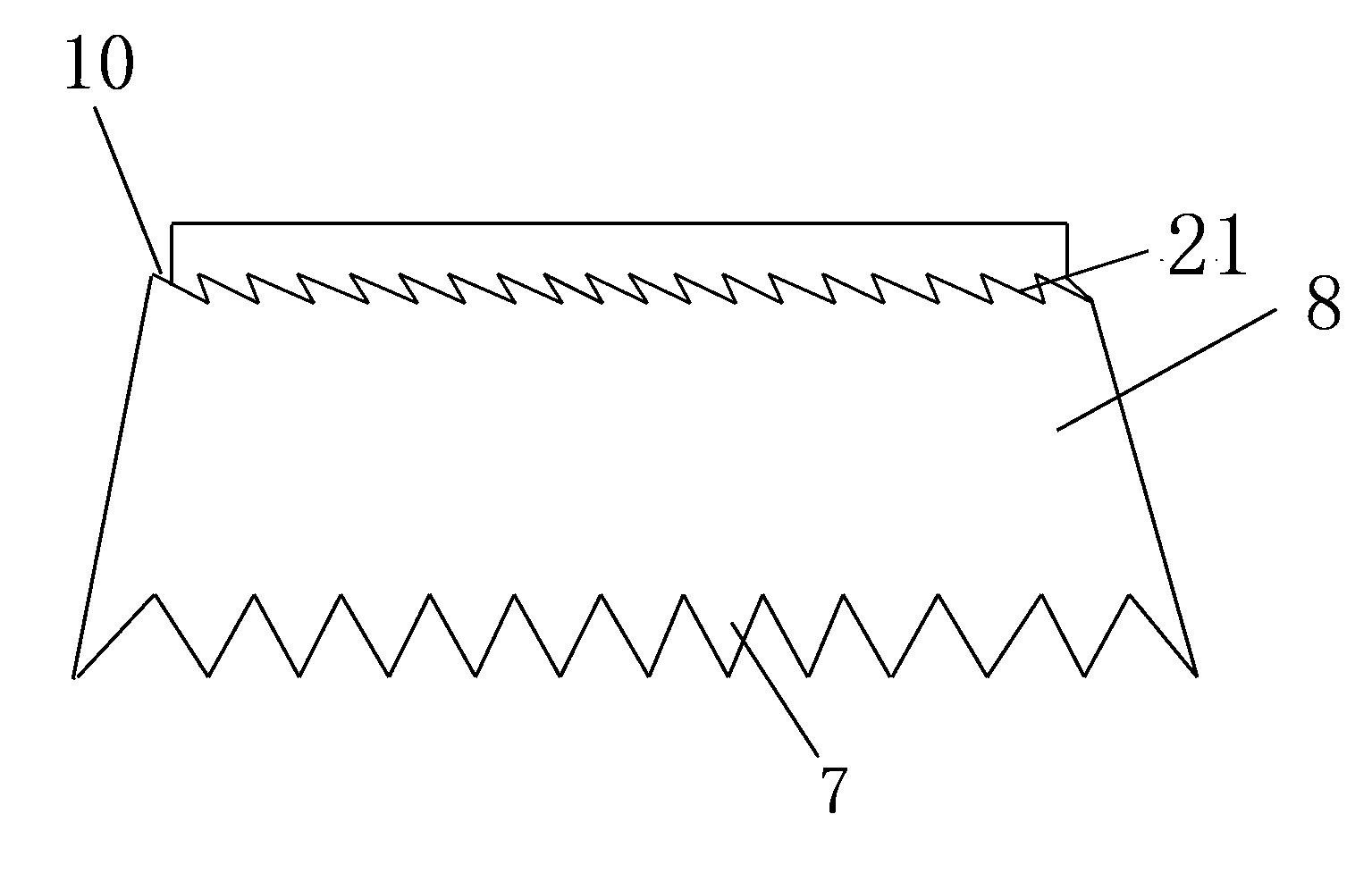

[0017] See attached picture. This embodiment includes a gland 1, an inner wall sleeve 3 and an outer wall sleeve 2. The outer wall sleeve 2 is provided with a pouring port 12 on the side; the inner wall sleeve 3 and the outer wall sleeve 2 The cover 1 is connected, and the upper end of the inner protective wall sleeve 3 forms a tapered tube 4 which is inserted into the pressure head 5 placed above the gland 1 and communicates with the mud hole 6 in the pressure head 5; The lower end of the tube 3 and the outer protective wall sleeve 2 is sheathed with a barrel shoe 8 with a cylindrical structure. The lower end of the barrel shoe 8 forms a cutting edge 7; the upper end of the barrel shoe 8 has a "convex" shape in radial section and has a ring shape. The outer bearing surface 10 and the inner bearing surface 11; the boot 8 is sleeved in the bore 9 between the inner wall sleeve 3 and the outer wall sleeve 2; the cutting edge 7 at the lower end of the boot 8 is serrated The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com