Part making method and device

A technology for parts and intermediate parts, applied in the field of making parts, can solve the problem of adding two-color or multi-color parts, and the color separation part of two-color or multi-color parts can only be set on the plane or flat surface of the product, so as to increase the diversity, The effect of high oxidation rate of secondary color coloring and reduction of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In Embodiment 1, a method for manufacturing a component is provided. In practical applications, the component may be an alloy component or a metal component, such as aluminum alloy, stainless steel, metal aluminum, metal iron, and the like.

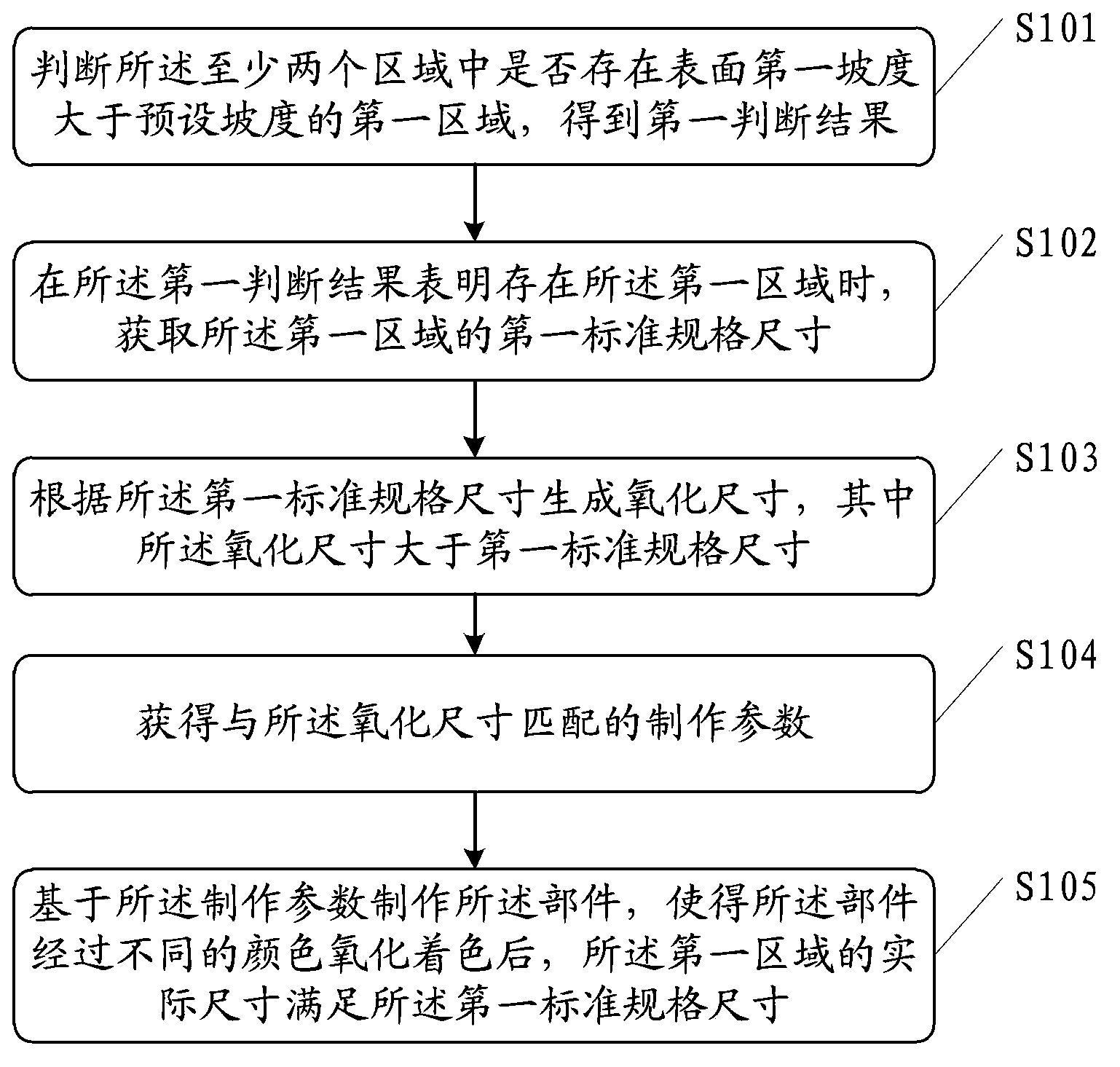

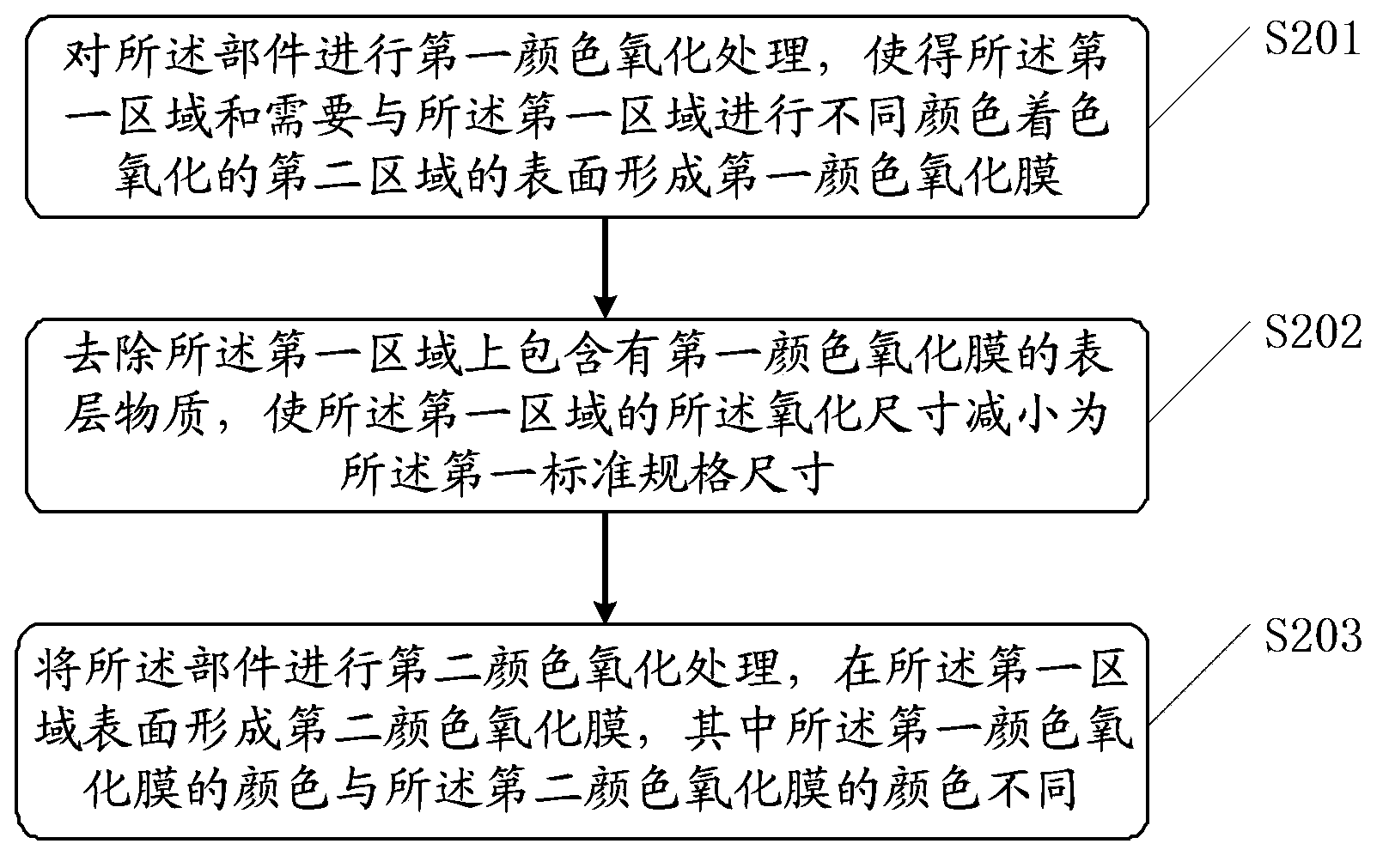

[0059] Please refer to figure 1 , a method for making a component provided in an embodiment of the present application, including:

[0060] Step 101: When at least two regions of the component need to be colored and oxidized with different colors, judge whether there is a first region with a first slope greater than a preset slope among the at least two regions, and obtain a first judgment result.

[0061] In the specific implementation process, the preset slope can be set to 30 degrees, because when the slope of the area of two-color or multi-color coloring oxidation is greater than 30 degrees, ink printing, jig masking and laser engraving are used to carry out double-color or multi-color coloring oxidation. There will be a pro...

Embodiment 2

[0088] Please refer to Figure 4 , the embodiment of the present application also provides a device for making components, including:

[0089] Judging module 401, configured to judge whether there is a first region whose surface first slope is greater than a preset slope in the at least two regions when at least two regions of the component need to be colored and oxidized in different colors, and obtain a first judgment result.

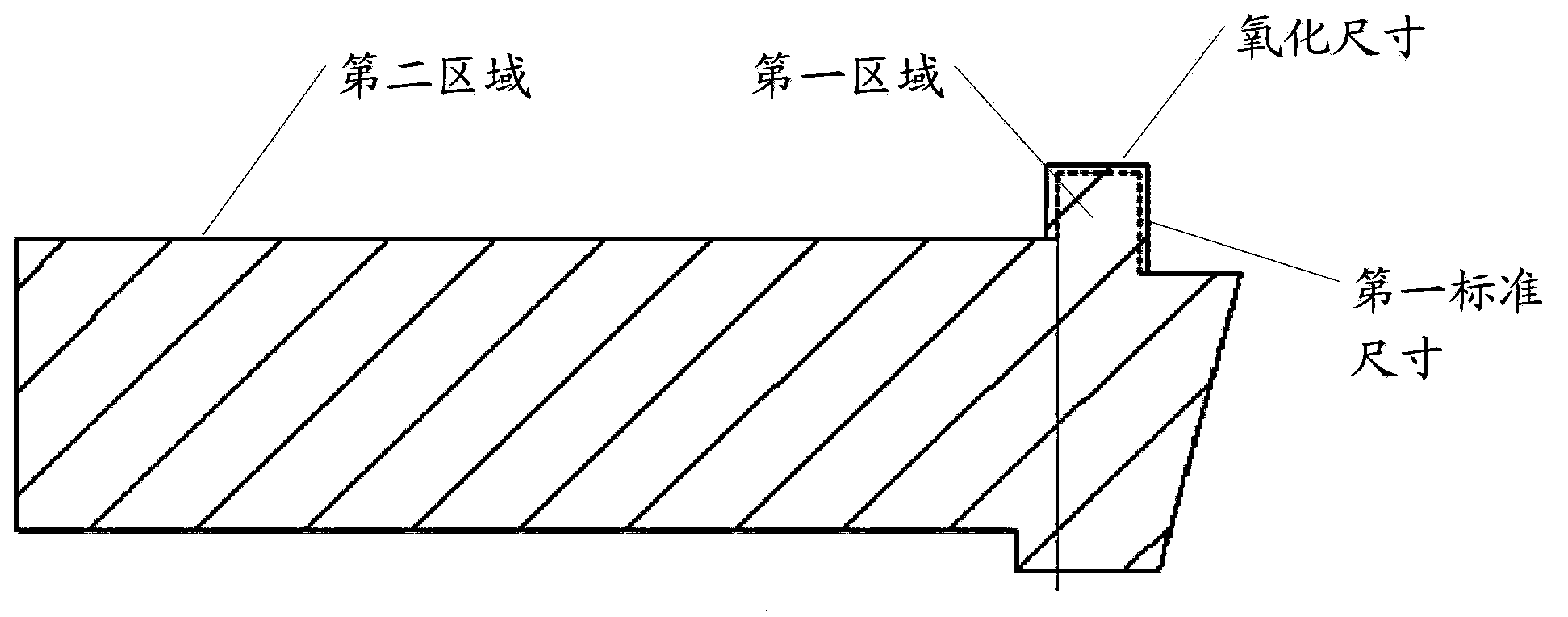

[0090] A data processing module 402, connected to the judging module 401, configured to obtain a first standard size of the first region when the first judging result indicates that the first region exists, and obtain the first standard size of the first region according to the first The standard gauge size generates an oxidized size, wherein the oxidized size is larger than the first standard gauge size, followed by obtaining fabrication parameters matching the oxidized size.

[0091] The production module 403 is connected to the data processing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com