Treatment method for hyperosmosis concentrated mash waste liquor

A treatment method and a concentrated mash technology are applied in the treatment field of high-osmotic concentrated mash waste liquid, which can solve the problems of secondary soil pollution, incomplete humification, incomplete harmlessness, etc., and achieve improved sugar content and flavor. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

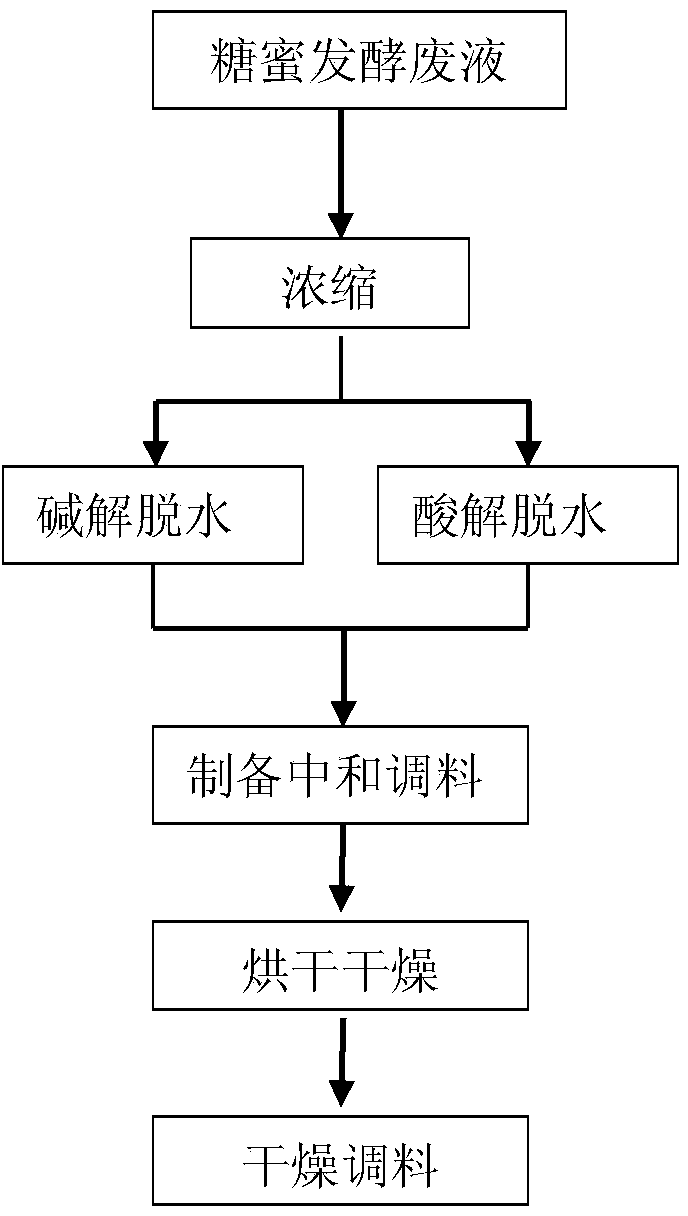

[0026] The molasses fermentation waste liquid of this embodiment comes from a large-scale cassava alcohol fermentation production enterprise in Guangxi. The harmless treatment steps are as follows:

[0027] 1) Concentration: Heat and evaporate at 65°C to concentrate the molasses fermentation waste liquid to an organic matter content of 55%, and then cool the concentrated liquid. After cooling, the concentrated liquid is divided into two parts for use, one part is used for alkaline hydrolysis dehydration, and the other part is used for acid Dehydration.

[0028] 2) Alkaline hydrolysis dehydration: Take part of the concentrated solution obtained in step 1), add 30% alkali hydrolysis agent (lime, the content of CaCO3 in the lime is ≥ 92%), alkali hydrolysis dehydration for 30 minutes under the condition of 150 r / min low-speed stirring, and then Add 10% calcium-magnesium phosphate fertilizer and 10% potassium fertilizer and stir evenly to obtain the alkaline solution seasoning. ...

Embodiment 2

[0033] The molasses fermentation waste liquid of this embodiment comes from a large-scale cassava alcohol fermentation production enterprise in Guangxi. The harmless treatment steps are as follows:

[0034] 1) Concentration: Heat and evaporate at 85°C to concentrate the molasses fermentation waste liquid to an organic matter content of 75%, and obtain the concentrated liquid for cooling. After cooling, the concentrated liquid is divided into two parts for use, one part is used for alkaline hydrolysis dehydration, and the other part is used for acid Dehydration.

[0035] 2) Alkaline hydrolysis dehydration: Take part of the concentrated solution obtained in step 1), add 35% alkali hydrolysis agent (liquid ammonia), and dehydrate it for 25 minutes under low-speed stirring at 200 r / min, then add 13% calcium magnesium phosphate fertilizer, 15 % potash fertilizer was stirred evenly to obtain the alkaline solution seasoning.

[0036] 3) Acidolysis and dehydration: take part of the ...

Embodiment 3

[0040] The molasses fermentation waste liquid of this embodiment comes from a large-scale cassava alcohol fermentation production enterprise in Guangxi. The harmless treatment steps are as follows:

[0041] 1) Concentration: Heat and evaporate at 50°C to concentrate the molasses fermentation waste liquid to an organic matter content of 60%, and then cool the concentrated liquid. After cooling, the concentrated liquid is divided into two parts for use, one part is used for alkaline hydrolysis dehydration, and the other part is used for acid Dehydration.

[0042] 2) Alkaline hydrolysis dehydration: take part of the concentrated solution obtained in step 1), add 25% alkali hydrolysis agent (ammonium carbonate powder), alkali hydrolysis dehydration for 40 minutes under the condition of 150 r / min low-speed stirring, then add 8% calcium magnesium phosphate fertilizer, 15% potash fertilizer was stirred evenly to obtain alkaline solution seasoning.

[0043] 3) Acid hydrolysis and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com