Bouncing mechanism of car trunk

A technology for trunks and trunk lids, which is applied to superstructures, vehicle parts, and subassemblies of superstructures, etc. It can solve the problems of increasing the number of parts, high cost, and abnormal noise caused by friction between torsion bar springs and plastic clips. Effects of weight reduction, material cost reduction, and noise elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

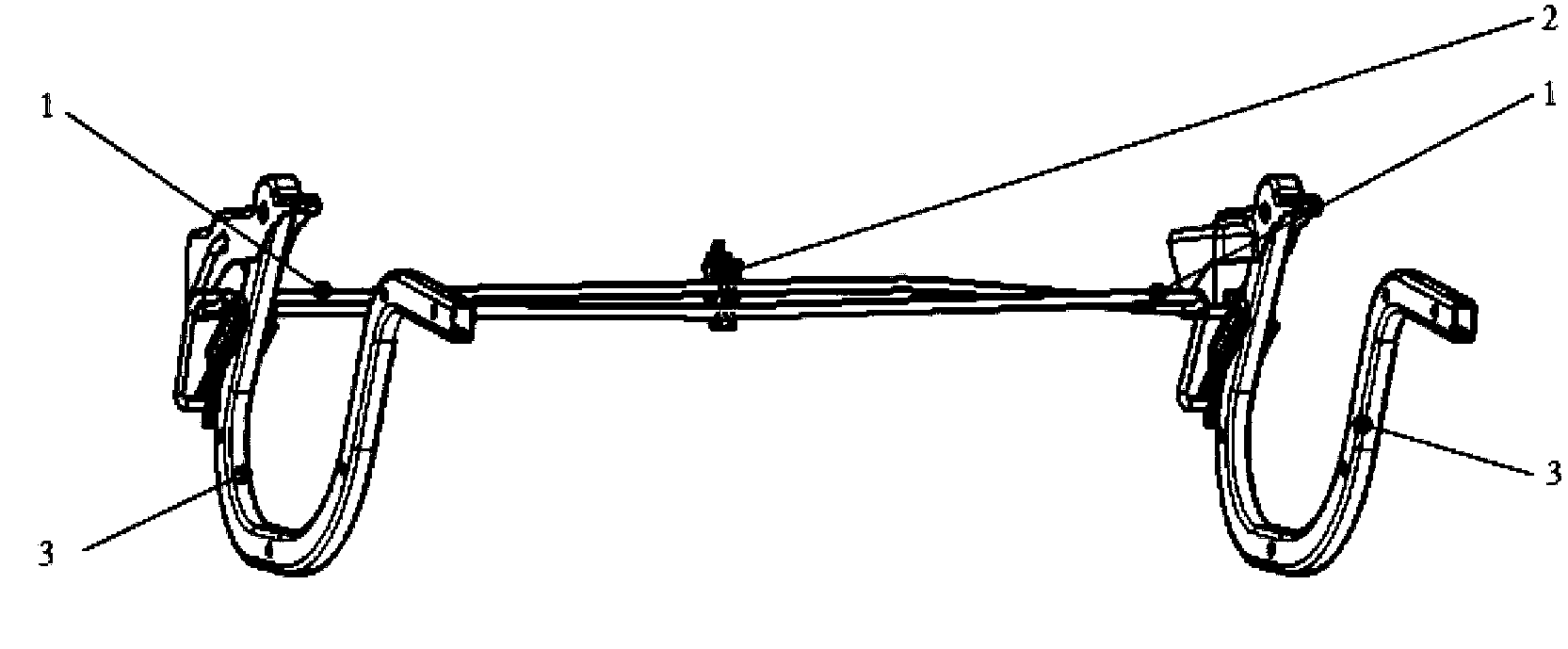

[0022] see figure 2 , This mechanism includes the torsion bar spring 4, the mounting seat plate 5, the torsion spring connecting rod 6, the bow arm 3 of the bow hinge, etc. Bow hinges, mounting seat plates and torsion bar springs are installed symmetrically on the left and right sides of the suitcase. The two sets of structures are the same. In this embodiment, the right set is taken as an example. The following descriptions and drawings are all about the structure and movement of the left side. The right side is completely symmetrical with it.

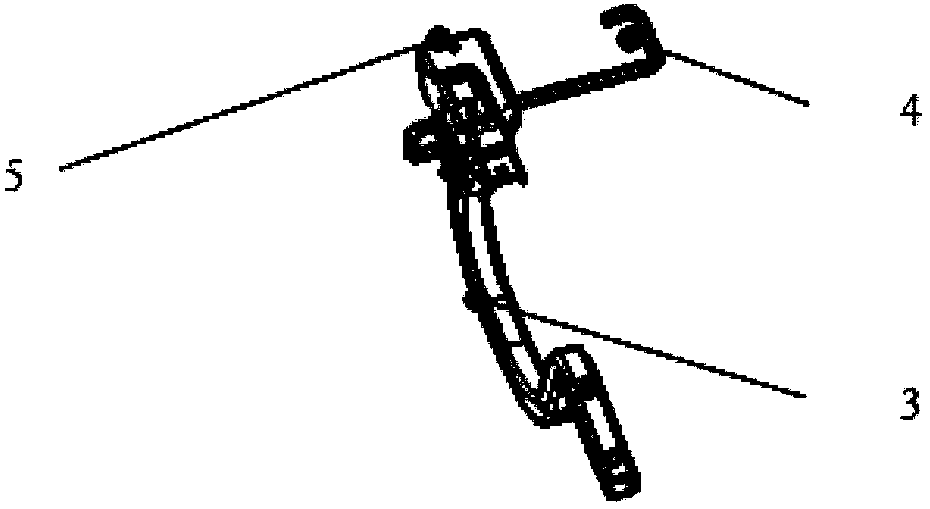

[0023] see image 3 , both the inner end 42 and the outer end of the torsion bar spring 4 are bent into an L shape.

[0024] see Figure 4 , the same as the existing arched hinge installation structure, one end of the arched arm 3 is hinged with the mounting seat plate 5, the mounting seat plate is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com