Dual-specification adaptor

A socket and dual-specification technology, applied in the field of dual-specification sockets, can solve the problems of occupying space, limited structural design of the sleeve, and difficulty for users to distinguish the size of the two sets of fitting holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

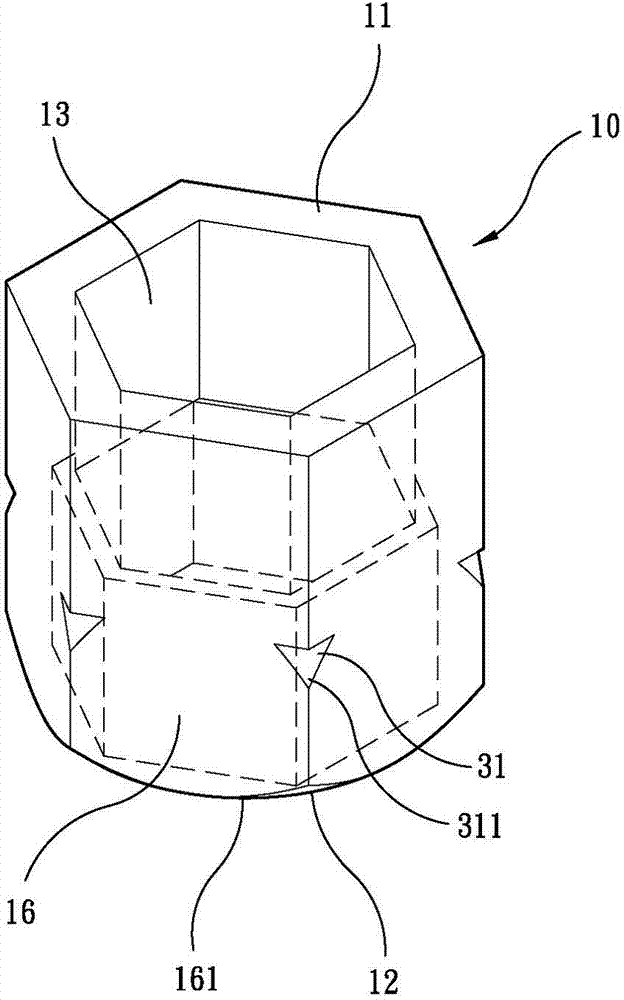

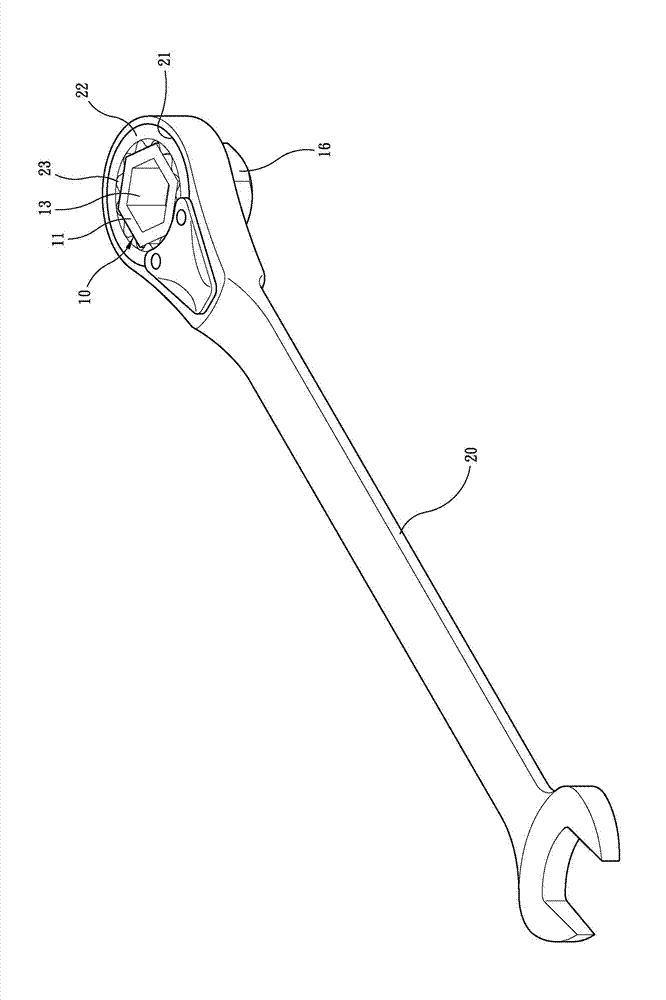

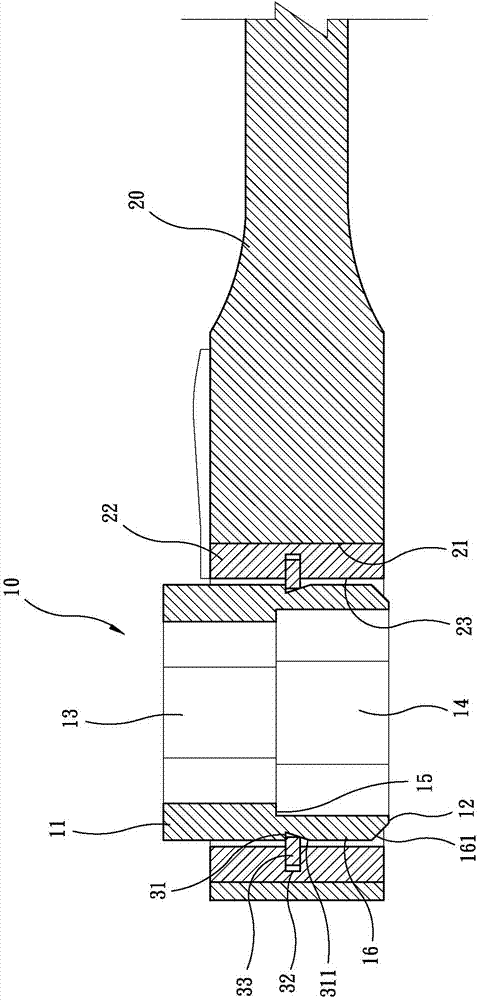

[0039] see Figure 1 to Figure 3 , the socket 10 of the present invention is a cylindrical body with a corresponding first end 11 and a second end 12. The first end 11 is recessed with a first fitting hole 13 capable of driving a screw lock assembly. As for the second end 12 is concavely provided with a second fitting hole 14, and the pitch diameter of the second fitting hole 14 is larger than the pitch diameter of the first fitting hole 13, so that it can drive another screw lock assembly with a larger size;

[0040] The shape of the first fit hole 13 and the second fit hole 14 is corresponding, and it can be as figure 1 Shown to form a regular hexagon, of course, can also be as Figure 4A , Figure 4B The formation of a regular square or a regular hexagonal quincunx as shown only needs to be able to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com