Ultrasonic cavitation intensifying device and ultrasonic cavitation intensifying method

An intensifying device and ultrasonic technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as poor economy, pollution of treated liquids, and restrictions on large-scale industrial applications of sonochemistry, and achieve Enhance the effect of cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

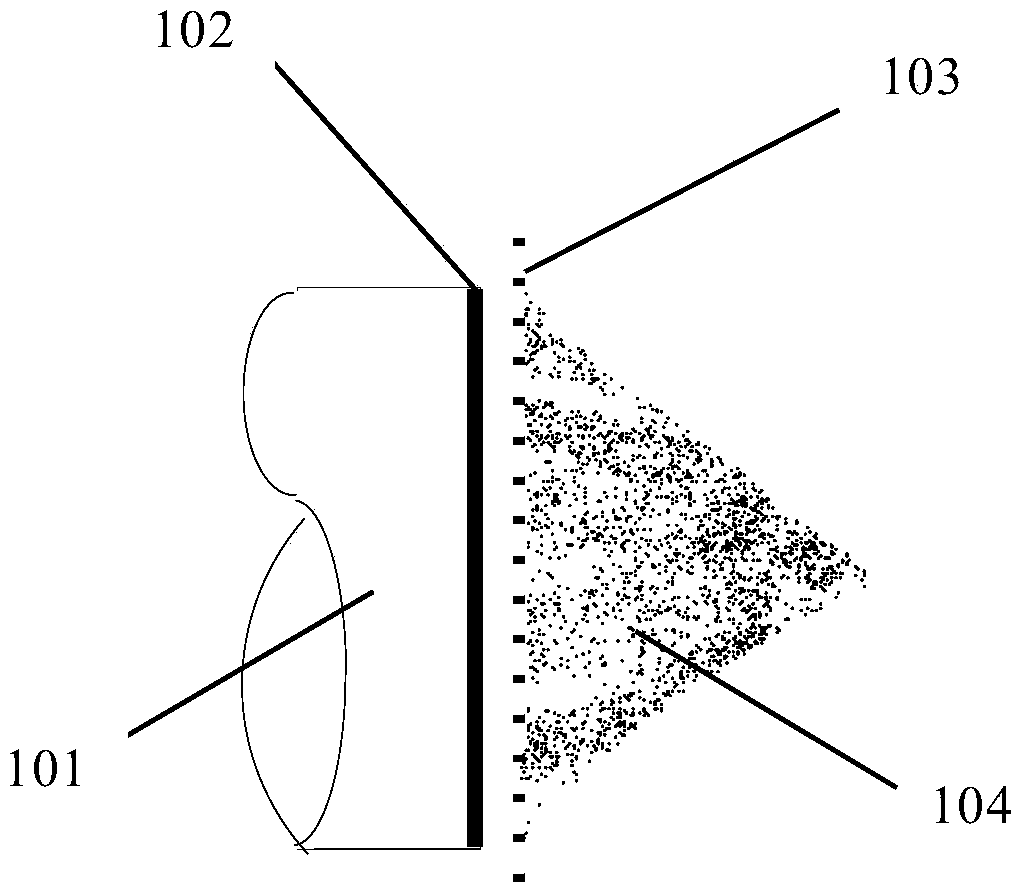

[0025] figure 1 It is a schematic diagram of the principle of the ultrasonic cavitation strengthening device in an embodiment of the present invention.

[0026] Such as figure 1 As shown, in this embodiment, the ultrasonic cavitation device includes a transducer 101, a transducer radiation surface 102 and a gas nucleus source 103, wherein:

[0027] The transducer 101 is used to convert electrical energy into ultrasonic waves. Specifically, in this embodiment, the average radiated sound intensity of the preferred transducer 101 is 2-6W / cm 2 , the working frequency is 10kHz-100kHz. Wherein, in this embodiment, it is preferable that the radiating surface of the transducer 101 is smooth without obvious flaws, and no other types of cavitation clouds (such as Smoker, CBS, etc.) adhere to the radiating surface of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com