Underwater crack corrosion jet nozzle

A technology of jet nozzles and jets, applied in the direction of injection devices, injection devices, liquid injection devices, etc., can solve the problems of limiting cavitation jet erosion ability and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and embodiments.

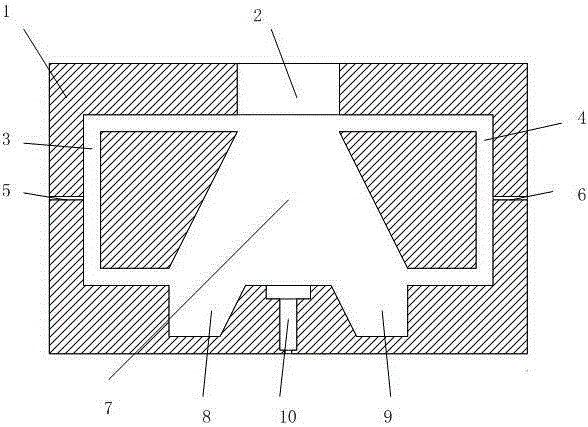

[0015] Such as figure 1 As shown, in the present invention, a jet inlet 2 is opened in the upper part of the valve body 1, a small to large conical oscillation cavity 7 is opened in the middle part, and a self-excited oscillation cavity 10 communicating with the oscillation cavity is opened in the lower part. The center of the cavity and the self-excited oscillation cavity 10 are located on the same axis; the left side of the valve body 1 is provided with a left feedback channel 3 which communicates with the end of the jet inlet 2 and the other end communicates with the left reflux cavity 8 at the bottom of the oscillation cavity. 1. On the right side, there is a right feedback channel 4 with one end communicating with the end of the jet inlet 2 and the other end communicating with the right reflux cavity 9 at the bottom of the oscillation cavity. The sides of the left r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com