Photovoltaic module capable of increasing power output

A photovoltaic module and a power-increasing technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as rough surface, unfavorable module power, and inability to absorb sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

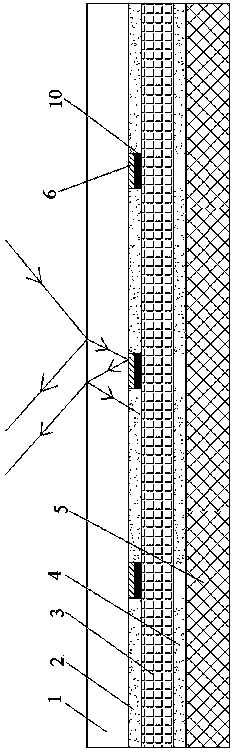

[0020] Such as figure 1 A photovoltaic module with increased power output is shown, including tempered glass 1, upper hot-melt adhesive film (EVA) 2, battery sheet 3, lower hot-melt adhesive film (EVA) 4 and back sheet stacked in sequence from top to bottom 5. It is characterized in that the battery sheet 3 is welded with an interconnection strip 9, and a layer of reflective layer 6 is coated on the interconnection strip 9. The width of the reflective layer 6 is consistent with the interconnection strip 9 . During the normal operation of this type of component, the sunlight originally irradiated on the interconnection bar 10 is now irradiated on the reflective layer 6, and the reflected light from the reflective layer 6 irradiates the interface between the tempered glass 1 and the air, part of the light is refracted, and the rest of the light is reflected Return to the direction of the battery sheet 3 and be absorbed. A large part of the light that was originally irradiated ...

Embodiment 2

[0022] Such as figure 1 A photovoltaic module with increased power output is shown, including tempered glass 1, upper hot-melt adhesive film (EVA) 2, battery sheet 3, lower hot-melt adhesive film (EVA) 4 and back sheet stacked in sequence from top to bottom 5. It is characterized in that the battery sheet 3 is welded with an interconnection strip 9, and a layer of reflective layer 6 is attached to the interconnection strip 9. The reflective layer 6 includes three layers, which are reflective material layer, isolation layer and self-adhesive layer from top to bottom. The width of the reflective layer 6 is consistent with that of the interconnection bars 9 , and the upper surface of the reflective layer 6 is directly attached to the toughened glass 1 through the upper hot-melt adhesive film 2 .

Embodiment 3

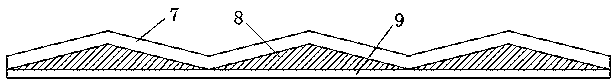

[0024] Such as figure 1 and 2 A photovoltaic module with increased power output is shown, including tempered glass 1, upper hot-melt adhesive film (EVA) 2, battery sheet 3, lower hot-melt adhesive film (EVA) 4 and back sheet stacked in sequence from top to bottom 5. It is characterized in that the battery sheet 3 is welded with an interconnection strip 9, and a layer of reflective layer 6 is attached to the interconnection strip 9. The reflective layer 6 is tooth-shaped, and the highest point of the tooth shape passes through a hot-melt adhesive film Connecting with the tempered glass 1, the tooth shape can increase the light receiving surface, further improving the utilization rate of sunlight. The tooth-shaped reflective layer has three layers, which are the reflective material layer 7, the tooth-shaped base layer 8 and the self-adhesive layer 9 from top to bottom. The profile angle is 170°. The width of the reflective layer 6 is consistent with that of the interconnectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com