Hydraulic ejecting, pushing and sliding installation method for transformer

An installation method and transformer technology, applied in the direction of transformer/reactor installation/support/suspension, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of high lifting command requirements, achieve simple laying, save mechanical costs, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated below by specific examples.

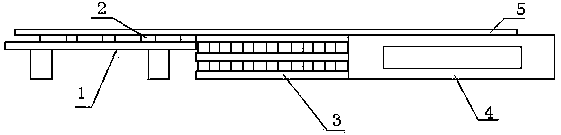

[0030] Such as figure 1 As shown, a hydraulic pushing and sliding installation method of a transformer, which includes steel (wooden) bent frames 2, four hydraulic jacks, two steel rails 5, two hydraulic pushing machines, steel plates, a number of sleepers 3, loaded with transformers Transport vehicle 1, transformer base 4; also include the following steps:

[0031] Step 1. Acceptance of the transformer on site: check that the oil tank is well sealed, that there are no impact marks and deformation on its surface, check that the oil tank cover and flange connecting bolts and sealing plates are complete, and that the fasteners are in good condition; for the transformer that is inflated and transported by the body, observe the transformer The nitrogen inflation pressure of the body (should be 0.01-0.03MPa), check whether the nitrogen replenishment device is reliable. Check the record value with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com